Perform step 1 stated above , then press scroll key until the display

shows

. Apply up/down key until value 0.0 is obtained. Press

scroll key for at least 3 seconds . The display will blink a moment and

a new value is obtained. Otherwise , if the display didn't blink or if

the obtained value is equal to -199.9 or 199.9, then the calibration

fails.

Perform step 1 stated above , then press scroll key until the display

shows

. Apply up/down key until value 0.0 is obtained. Press

scroll key for at least 3 seconds . The display will blink a moment and

a new value is obtained. Otherwise , if the display didn't blink or if

the obtained value is equal to -199.9 or 199.9, then the calibration

fails.

Perform step 1 stated above , then press scroll key until the display

shows

. Apply up/down key until value 0.1 is obtained.

Press scroll key for at least 3 seconds. The display will blink a moment

and the new value 0.0 is obtained. Otherwise , the calibration fails.

Perform step 1 stated above , then press scroll key until the display

shows

. Apply up/down key until value 0.1 is obtained.

Press scroll key for at least 3 seconds. The display will blink a moment

and the new value 0.0 is obtained. Otherwise , the calibration fails.

Perform step 11 to calibrate

of

compensation if

required, otherwise , perform step 11N to use a nominal value for the

cold junction gain if a

for calibration is

.

gain

cold junction

test chamber

not available

Perform step 11 to calibrate

of

compensation if

required, otherwise , perform step 11N to use a nominal value for the

cold junction gain if a

for calibration is

.

gain

cold junction

test chamber

not available

Setup the equipments same as step 10. The unit under calibration is

powered in a still-air room with temperature

. Stay at least 20

minutes for warming up . The calibrator source is set at 0.00 °C with

internal compensation mode.

50±3 °C

Setup the equipments same as step 10. The unit under calibration is

powered in a still-air room with temperature

. Stay at least 20

minutes for warming up . The calibrator source is set at 0.00 °C with

internal compensation mode.

50±3 °C

Step 11.

Step 11.

Step 11N.

Step 11N.

The unit under calibration is powered in a still-air room with

temperature

. Stay at least 20 minutes for warming up. The

DIP Switch is located at TC input .

Perform step 1 stated above, then press scroll key until the display

shows

. Apply up/down key until value 0.00 is obtained .

Press scroll key at least 3 seconds. The display will blink a moment

and a new value is obtained . Otherwise , if the display didn't blink

or if the obtained value is equal to -5.00 or 40.00, then the calibration

fails.

25±3 °C

The unit under calibration is powered in a still-air room with

temperature

. Stay at least 20 minutes for warming up. The

DIP Switch is located at TC input .

Perform step 1 stated above, then press scroll key until the display

shows

. Apply up/down key until value 0.00 is obtained .

Press scroll key at least 3 seconds. The display will blink a moment

and a new value is obtained . Otherwise , if the display didn't blink

or if the obtained value is equal to -5.00 or 40.00, then the calibration

fails.

25±3 °C

*

*

Final step

Final step

Step 12.

Step 12. Set the DIP switch to your desired position ( refer to

).

section 1-3

Set the DIP switch to your desired position ( refer to

).

section 1-3

This setup is performed in a

, hence it is

recommended to use a computer to perform the procedures.

high temperature chamber

This setup is performed in a

, hence it is

recommended to use a computer to perform the procedures.

high temperature chamber

103

It is

to use this step 11N, since the

to achieve rated accuracy by this step.

not recommended

cold junction

gain is not able

It is

to use this step 11N, since the

to achieve rated accuracy by this step.

not recommended

cold junction

gain is not able

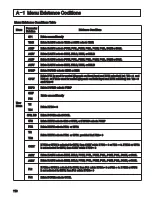

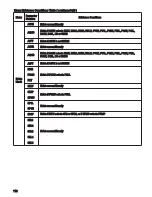

Automatic Calibration Procedures

Automatic Calibration Procedures

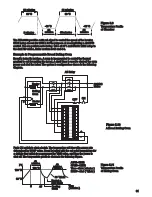

The programming port ( See

) of

-8300 can be used for

automatic calibration.

The equipments required for automatic calibration are available upon request.

Section 2-18

ETR

The programming port ( See

) of

-8300 can be used for

automatic calibration.

The equipments required for automatic calibration are available upon request.

Section 2-18

ETR

Caution:

Caution: