2 5 Sensor Installation Guidelines

2 5 Sensor Installation Guidelines

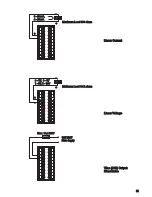

Proper sensor installation can eliminate many problems in a control system. The

probe should be placed so that it can detect any temperature change with

minimal thermal lag. In a process that requires fairly constant heat output, the

probe should be placed closed to the heater. In a process where the heat

d e m a n d i s v a r i a b l e , t h e p r o b e s h o u l d b e c l o s e d t o t h e w o r k a r e a . S o m e

experiments with probe location are often required to find this optimum position.

In a liquid process, addition of a stirrer will help to eliminate thermal lag. Since

the thermocouple is basically a point measuring device, placing more than one

thermocouple in parallel can provide an average temperature readout and

produce better results in most air heated processes.

P r o p e r s e n s o r t y p e i s a l s o a v e r y i m p o r t a n t f a c t o r t o o b t a i n p r e c i s e

measurements. The sensor must have the correct temperature range to meet

the process requirements. In special processes the sensor might need to have

different requirements such as leak-proof, anti-vibration, antiseptic, etc.

S t a n d a r d s e n s o r l i m i t s o f e r r o r a r e ± 4 F ( ± 2 ° C ) o r 0 . 7 5 % o f s e n s e d

temperature (half that for special ) plus drift caused by improper protection or an

over-temperature occurrence. This error is far greater than controller error and

c a n n o t b e c o r r e c t e d o n t h e s e n s o r e x c e p t b y p r o p e r s e l e c t i o n a n d

replacement.

°

24