5 10 RS-485

5 10 RS-485

A

making plant has 5 production lines. Each production line is equipped

with 16 x ETR-8300s to control the temperature for each

. This process

requires the ability to program each controller and monitor the process in a

control room. This method would serve to improve the quality, efficiency and

productivity. A cost effective solution for the above application is to use 80

units of the

plus an

and Specview or ETR

PC based software.

tile

kiln

ETR-8300 / ETR-4300-XXXXXX1

SNA10B Smart Network

Adaptor

-Net

A

making plant has 5 production lines. Each production line is equipped

with 16 x ETR-8300s to control the temperature for each

. This process

requires the ability to program each controller and monitor the process in a

control room. This method would serve to improve the quality, efficiency and

productivity. A cost effective solution for the above application is to use 80

units of the

plus an

and Specview or ETR

PC based software.

tile

kiln

ETR-8300 / ETR-4300-XXXXXX1

SNA10B Smart Network

Adaptor

-Net

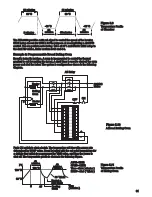

The system is installed as shown in the following diagram.

The system is installed as shown in the following diagram.

96

Kiln 1

Kiln 1

Kiln 5

Kiln 5

Kiln 2

Kiln 2

Kiln 3

Kiln 3

Kiln 4

Kiln 4

TX1

TX1

TX2

TX2

65

2

66

80

Control Room

Control Room

PC

( ETR-Net )

PC

( ETR-Net )

RS-232

SNA10B

TX1

TX2

Twisted-pair wire, max. distance .5 Mile

Twisted-pair wire, max. distance .5 Mile

Figure 5.17

Figure 5.17

RS-485 Applications

RS-485 Applications

Terminator, 220 ohms/0.5W

Terminator, 220 ohms/0.5W

ETR-8300

Out1 Out2

Alm1 Alm2

TX1

TX2

ETR-8300

Out1 Out2

Alm1 Alm2

TX1

TX2

ETR-8300

Out1 Out2

Alm1 Alm2

ETR-8300

Out1 Out2

Alm1 Alm2

ETR-8300

Out1 Out2

Alm1 Alm2

16

ETR-8300

Out1 Out2

Alm1 Alm2

1

TX2

TX2

TX2

TX2

TX1

TX1

TX1

TX1