INSTRUCTION

MANUAL

MANUAL #27

1/8 DIN Solid State Temperature

Indicator Model ETR-9004

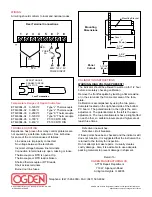

All temperature indicators in this series are made to fit

into panel cut-outs which measure 1

13

⁄

16

” x 3

5

⁄

8

” (46mm x

92mm). A minimum of 3

1

⁄

2

” (89mm) in depth is required

for electrical clearances of rear terminal connections.

The following specifications are common to all models:

INPUT

Thermocouple (T/C)

Type K, J. Specified on

Control Label.

RTD

PT 100 ohm, 2 or 3-wire

(

= .00385) DIN

(

= .00392) JIS

Cold Junction

Compensation

Automatic

Input Break

Built-in, upscale on open

sensor.

Input Impedance

1M ohm.

Common Mode

Rejection (CMR)

CMRR 120dB, Min.

Normal Mode

Rejection (NMR)

NMRR 60dB, Min. (60Hz)

POWER

Rating

120/240VAC field

selectable, 50/60Hz.

12-24VDC models

available on special order.

Accuracy

0.2% of SPAN.

Consumption

Less than 3VA.

ENVIRONMENTAL & PHYSICAL

Operating Temperature 10° to 125°F (-12 to 52°C).

Humidity

5 to 90% RH (non-

condensing).

Insulation

20M ohm Min., (5000VDC).

Breakdown

2000VAC, 50/60Hz,

1 minute.

Vibration

10 - 55Hz, Amplitude

1.0mm.

Shock

660 ft./S

2

(20g.)

Weight

11 oz. (312 grams)

DIMENSIONS

H – 1

7

⁄

8

” (48mm)

W – 3

3

⁄

4

” (96mm)

D – 3

1

⁄

4

” (83mm)

Depth behind panel – 3”

(76mm)

DIN Case

Plastic, with screw

terminals on rear,

adjustable brackets for

panel mounting.

MOUNTING

When mounting the instrument, it is important the

instrument remains within the ambient temperature

range of 10 to 125°F. Mounting it in any position is

permissible. After inserting the instrument into the

panel, secure it with the mounting bracket provided with

each unit.

•

Both solderless terminals or “stripped” leads

can be used for power leads. Only “stripped” leads

should be used for thermocouple connections to

prevent compensation and resistance errors.

•

Take care not to over-tighten the terminal screws.

•

Unused control terminals should not be used as

jumper points as they may be internally connected,

causing damage to the unit. This indicator is not

to be used in hazardous locations as defined in

Article 500 of the National Electric Code.