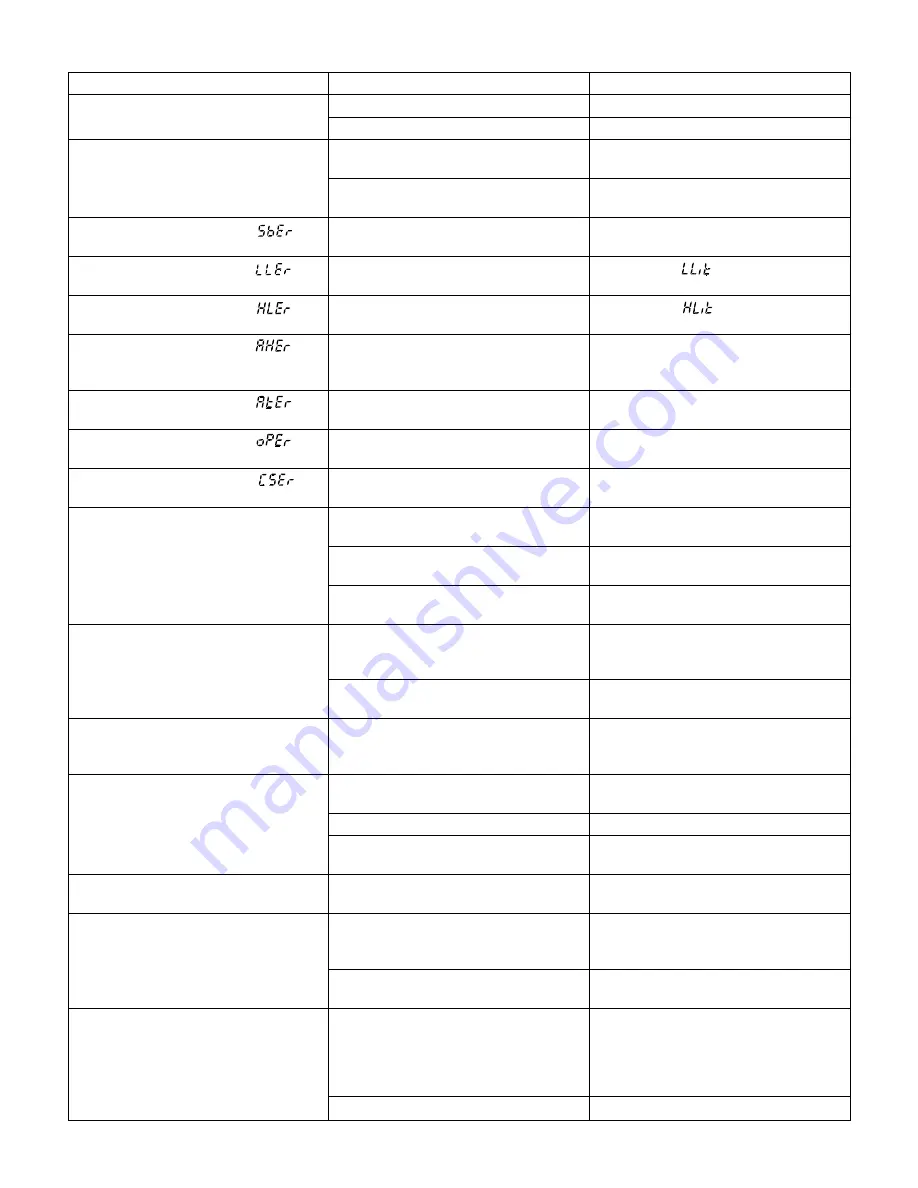

Table 7.1 Troubleshooting

Symptom

1.) LED’s will not light.

2.) Some segments of the display or

LED lamps not lit or lit erroneous-

ly.

3.) Process Display shows:

4.) Process Display shows:

5.) Process Display shows:

6.) Process Display shows:

7.) Process Display shows:

8.) Process Display shows:

9.) Process Display shows:

10.) Display Unstable

11.) Considerable error in tempera-

ture indication.

12.) Display goes in reverse direction

(counts down scale as process

warms).

13.) No heat or output

14.) Heat or output stays on but indi-

cator reads normal.

15.) Control abnormal or operation

incorrect.

16.) Display blinks, entered values

change by themselves.

Probable Cause(s)

—No power to instrument.

—Power supply defective.

—LED display or LED Lamp defec-

tive.

—Related LED driver defective.

—Sensor break error.

—Process value beyond the low

range setpoint.

—Process value beyond the high

range setpoint.

—Analog hybrid module damage.

—Incorrect operation of auto tune

procedure. Prop. Band set to 0.

—Manual mode is not allowable for

an ON-OFF control system.

—Check sum error, values in memory

may have changed accidentally.

—Analog portion or A-D converter

defective.

—Thermocouple, RTD or sensor

defective.

—Intermittent connection of sensor

wiring

—Wrong sensor or thermocouple

type. Wrong input mode selected.

—Analog portion A-D converter

defective.

—Reversed input wiring of sensor.

—No heater power (output), incorrect

output device used.

—Output device defective.

—Open fuse outside of the instru-

ment.

—Output device shorted, or power

service shorted.

—CPU or EEPROM (non-volative

memory) defective. Key switch

defective.

—Operation of control incorrect.

—Electromagnetic interference (EMI),

or Radio Frequency Interface (RFI).

—EEPROM defective.

Solution(s)

—Check power line connections.

—Replace power supply board.

—Replace LED display or LED lamp.

—Replace the related transistor or IC

chip.

—Replace RTD or sensor.

—Use manual mode operation.

—Re-adjust

value.

—Re-adjust

value.

—Replace module. Check for outside

source of damage such as tran-

sient voltage spikes.

—Repeat procedure. Increase Prop.

Band to a number larger than 0.

—Increase proportional band.

—Check and reconfigure the control

parameters.

—Replace related components or

board.

—Check thermocouple, RTD or sen-

sor.

—Check sensor wiring connections.

—Check sensor or thermocouple type

and if proper input mode was

selected.

—Replace related components or

board.

—Check and correct.

—Check output wiring and output

device.

—Replace output device.

—Replace output fuse.

—Check and replace.

—Check and replace.

—Read the operation procedure care-

fully.

—Suppress arcing contacts in system

to eliminate high voltage spike

sources. Separate sensor and con-

troller wiring from “dirty” power

lines, ground heaters.

—Replace EEPROM.