ADVENTURER BALANCES

EN-13

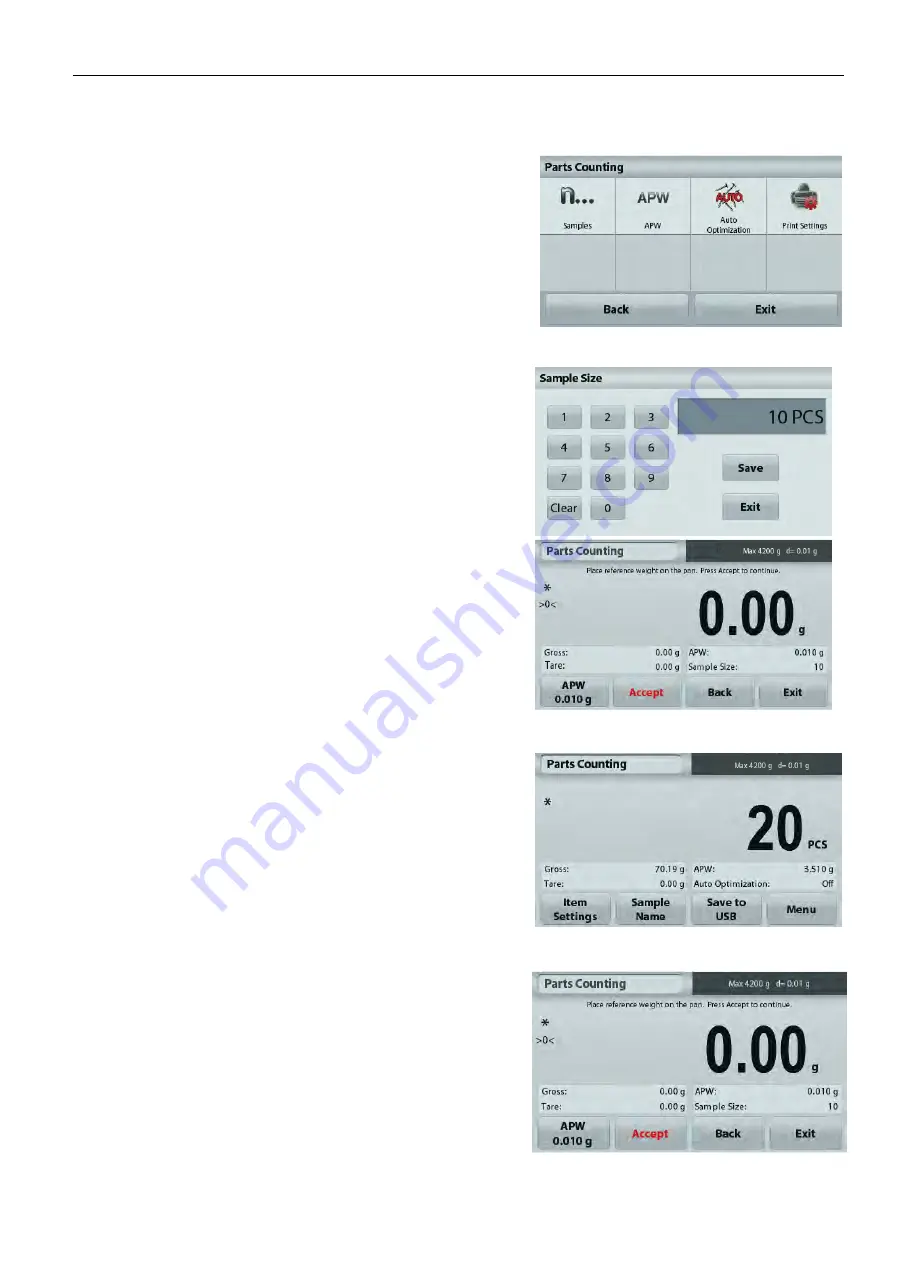

4.2.1 Item Settings

To view or adjust the current settings

Touch the

Item Settings

button. The Settings screen appears.

Samples:

The sample size can be 1 to 10 000 pieces.

The default sample size is 10. Once a sample size is

changed, the balance will immediately open the

recalculate APW screen, expecting to establish a new

APW.

To adjust the sample size, touch the

Samples

button.

A numeric input window appears.

Use the keys to enter the desired sample size,

then press

Save

.

The next screen appears, with the message to place

the reference weight on the pan.

Place the reference weight on the pan, then touch

Accept

to capture the value, the screen shows number

of pcs.

Establish an Average Piece Weight (APW):

Each time a new type of part is counted, the

nominal weight of one piece (Average Piece

Weight or APW) must be established using a

small quantity of pieces. This APW is stored

until replaced by another APW.

There are two methods to establish the APW

value:

1. The actual APW is known

2. The APW must be derived by weight. For

this case the current sample size will be used

www.

GlobalTestSupply

.com

Find Quality Products Online at:

sales@GlobalTestSupply.com