CHAPTER 3 MAINTENANCE PROCEDURES

Ohaus Corporation www.ohaus.com

24

Navigator Series Service Manual

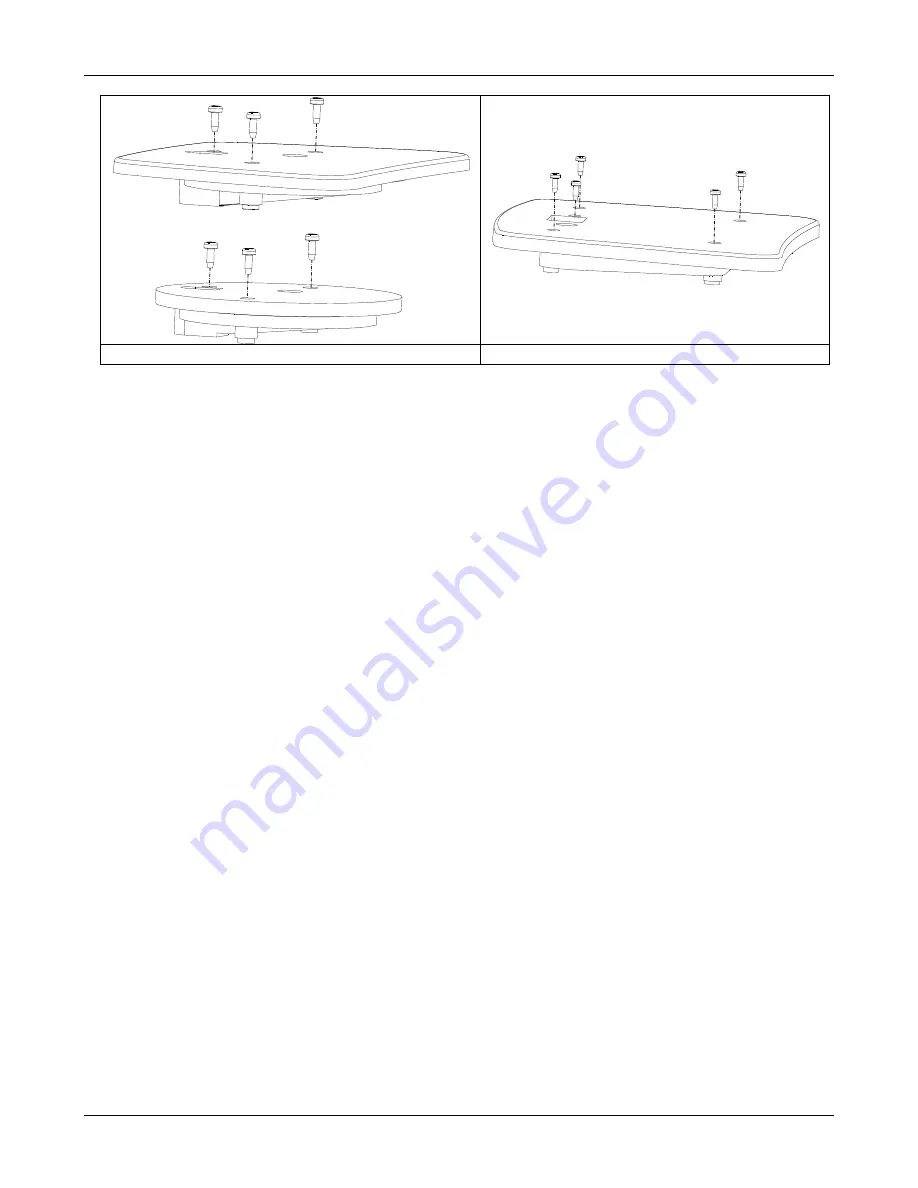

NV Models

NVL and NVT Models

Figure3-6. Down Stop Adjustment Screws

To adjust the down-stops on the applicable models follow the procedures below. Models without

adjustable down-stops need no action.

To ensure full weight reading:

The proper down-stop adjustment will allow full weight reading provided the center of the mass is

less than ½ the distance from the pan center to the pan edge. To allow for tolerance this adjustment

is being done at 120% of scale capacity or at scale capacity but ¾ of the distance to the pan edge.

To protect the load cell:

To protect the load cell from physical damage the down-stops should touch at about 200% of scale

capacity. Again to allow for adjusting tolerance the adjustment is made using a 150% weight.

The adjustment screws in the Sub-Pan can be adjusted with a #2 cross-recess (Phillips) screw

driver. Each adjustment screw should contact the Base when 120% to 150% of the scale capacity is

placed in the center of the 4 quadrants of the scale. The Top Housing must be removed to visually

check if the down-stops are touching. Turn the adjustment screw counterclockwise to increase the

clearance and clockwise to decrease the clearance.

An easy method to check the down-stop adjustment is to use the scales weight reading to detect if

the down-stop is touching. This method can only check if the down-stop is set too close preventing

accurate weighing.

1. Place 100%

scale’s capacity in the center of the Pan.

2. Note the reading.

3. Move the mass ¾ of the way (between the center and the edge) to the front of the Pan.

Note any significant difference in the displayed weight reading.

4. Repeat the test for the back, left, and right position of the Pan.

5. If there was a weight reading change turn the adjustment screw nearest the quadrant

counterclockwise ¼ turn. Repeat the test to see if it is corrected.

6. If the weight is placed at the edges of the pan there may be a weight change which indicates

the down-stop is working and this is okay.

Summary of Contents for Navigator NV1101

Page 1: ...SERVICE MANUAL Navigator Series Scales ...

Page 2: ......

Page 6: ......

Page 56: ......

Page 57: ......