CHAPTER 1

GETTING STARTED

Ohaus Corporation www.ohaus.com

1-8

3000 T32ME & MC Indicator Service Manual

1.8 RS232 INTERFACE CONNECTION

The T32 has a bi-directional RS232 interface for communication with printers and computers.

When communication is used, data can be output various ways, depending on PRINT menu

settings.

For RS232 cable connections, see Section 1.5.2, page 1-5.

1.8.1 Setting Communications Parameters

The T32 Indicator’s default communication parameters are baud rate 9600 bits per second

(bps), 8 databits, no parity

,

Handshake XON/XOFF, Stable Only Off, and Autoprint Off.

To change these settings use the PRINT menu, as follows:

1. Press and hold

TARE/Menu

until

C.A.L.

appears. Press

No

.

S.E.t.U.P

appears.

Press

No

.

r.E.A.d

appears. Press

No

.

M.O.d.E

appears. Press

No.

U.N.I.t

appears.

Press

No

.

P.r.i.n.t

appears. Press

Yes

.

rESEt

appears. Press

No.

2.

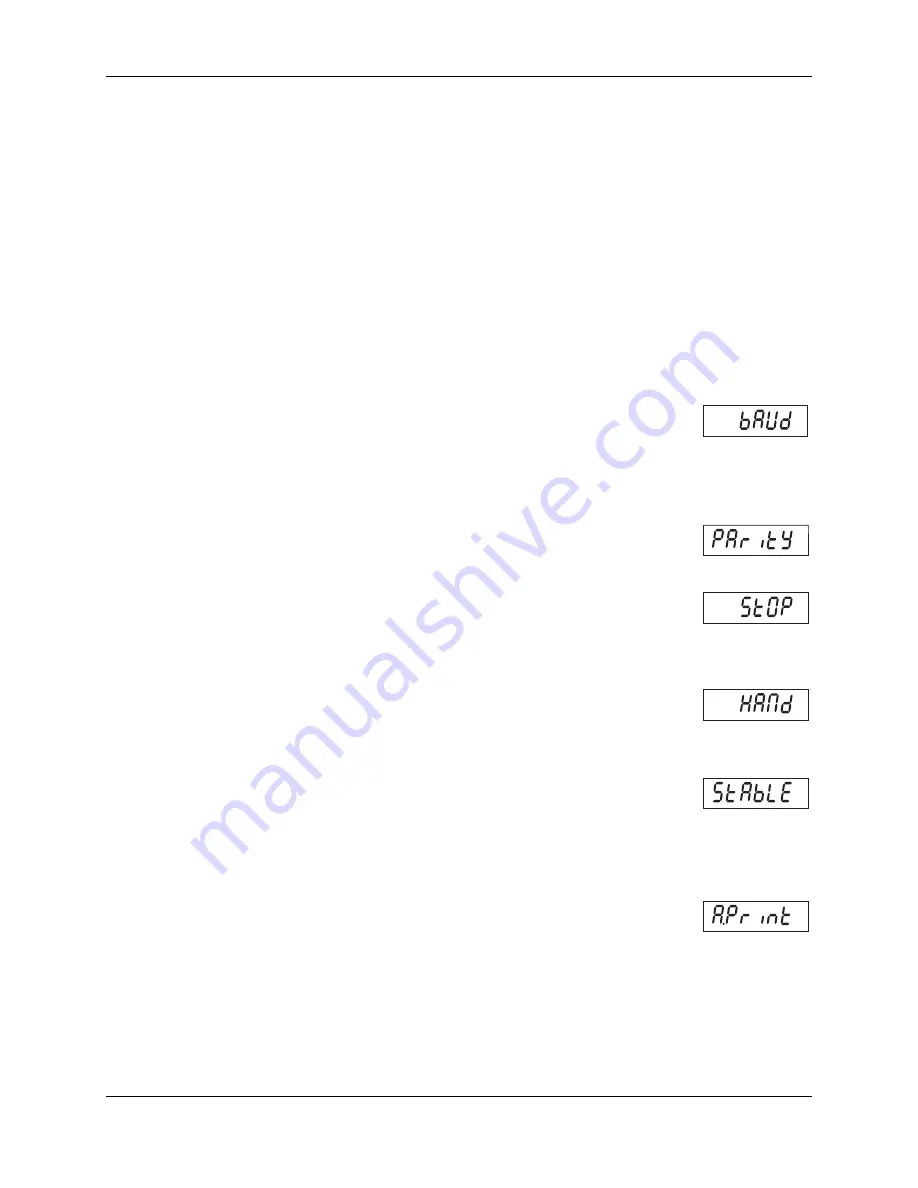

bAUd

appears. Press

Yes

.

3. The default Baud rate setting,

9600

bps, appears. To change the setting, press

No.

The menu cycles to the next setting each time you press No: first 9600, then 300, 600,

1200, 2400, 4800, and 9600 again. Press Yes when the desired setting appears. bAUd

appears again. Press No.

4.

PAritY

appears. Press

Yes

. The default Parity setting,

8

NONE

, appears. To change the setting, press

No

.

5. The menu cycles to the next setting each time you press No:

first 7 Even, then 7 Odd, 7 None, and 8 None again. Press

Yes

to accept a setting.

PAritY

appears again. Press

No

.

6.

StOP

appears. Press

Yes

. The default Stop Bit setting,

1

, appears.

To change the setting, press

No

.

7. The menu toggles to the next setting each time you press No:

first 1, then 2, then 1 again. Press

Yes

when the desired setting

appears.

StOP

appears again. Press

No

.

8.

HANd

appears. Press

Yes

. The default Handshake setting,

On-Off

(Xon/Xoff),

appears. To change the setting, press

No

.

9. The menu toggles to the next setting each time you press No: first Off,

then On-Off, then Off again. Press

Yes

when the desired setting

appears.

HANd

appears again. Press

No

.

10.

StAbLE

appears. Press

Yes

. The Stable setting allows the Indicator to print values

only when the stability criteria are met. To choose

ON

, press

Yes

. If you press

No

,

Off

appears. Press

Yes

to accept a setting. Then

StAbLE

appears. Press

No

.

11.

A.Print

appears. Press

Yes

. Auto Print sets printing to occur each

time stability criteria are met (

ON.StAB

), or at a defined interval

(

INtEr

), or continuously (

CONt

). The default setting is

Off

. Press

No

until the preferred setting appears. Then press

Yes

.

A.Print

appears.

Press

No

.

INtEr

appears.

12. If

INtEr

was selected, use the

INtEr

sub-menu to set the interval, from 1 to 3600

seconds. Press

No

to advance,

Back

to regress, and

Yes

to accept a setting. After you

press

Yes

,

INtEr

appears again. Press

No

twice, then

Yes

when

End

appears,

No

when

P.r.i.n.t

appears,

No

again, and

Yes

when End appears again to exit menu mode.

Summary of Contents for T32ME

Page 2: ......

Page 4: ......

Page 45: ......

Page 46: ...80253153 P N 80253153 SERVICE MANUAL 3000 SERIES T32MC T32ME INDICATORS...