CHAPTER 1

GETTING STARTED

1.9 CALIBRATION

Three calibration processes are available: Zero, Span, and Linearity Calibration. In addition, a

Calibration Test and Geographical Adjustment Factor setting are accessible from the CAL

menu.

Preliminary Steps

:

1. Be sure appropriate calibration masses are available before beginning calibration.

2. Be sure the scale base is level and stable during the entire calibration process.

3. If LFT is set to On, calibration is unavailable.

To set LFT to OFF, see Section 1.10, page 1-13.

Note:

To use the LFT mode again after turning it off, it is necessary to have the

Indicator locked and sealed by local Weights and Measures authorities.

4. If the Calibration Menu is locked in the Menu Lock submenu, turn it back on:

– Press and hold

TARE/Menu

until

C.A.L.

appears, then press

No

continuously until:

–

L.MENU

appears. Press

Yes

.

RESET

appears. Press

No

.

–

L.CAL

appears. Press

Yes

.

OFF

flashes. Press

Yes

.

– Press

No

continuously until

End.LM

appears. Press

Yes

.

–

L.Key

appears. Press

No

.

END

appears. Press

Yes

to exit menu mode.

5. Allow the Indicator to warm up for approximately ten minutes after stabilizing to room

temperature.

6. To abort calibration, press the

Exit

button anytime during the calibration process.

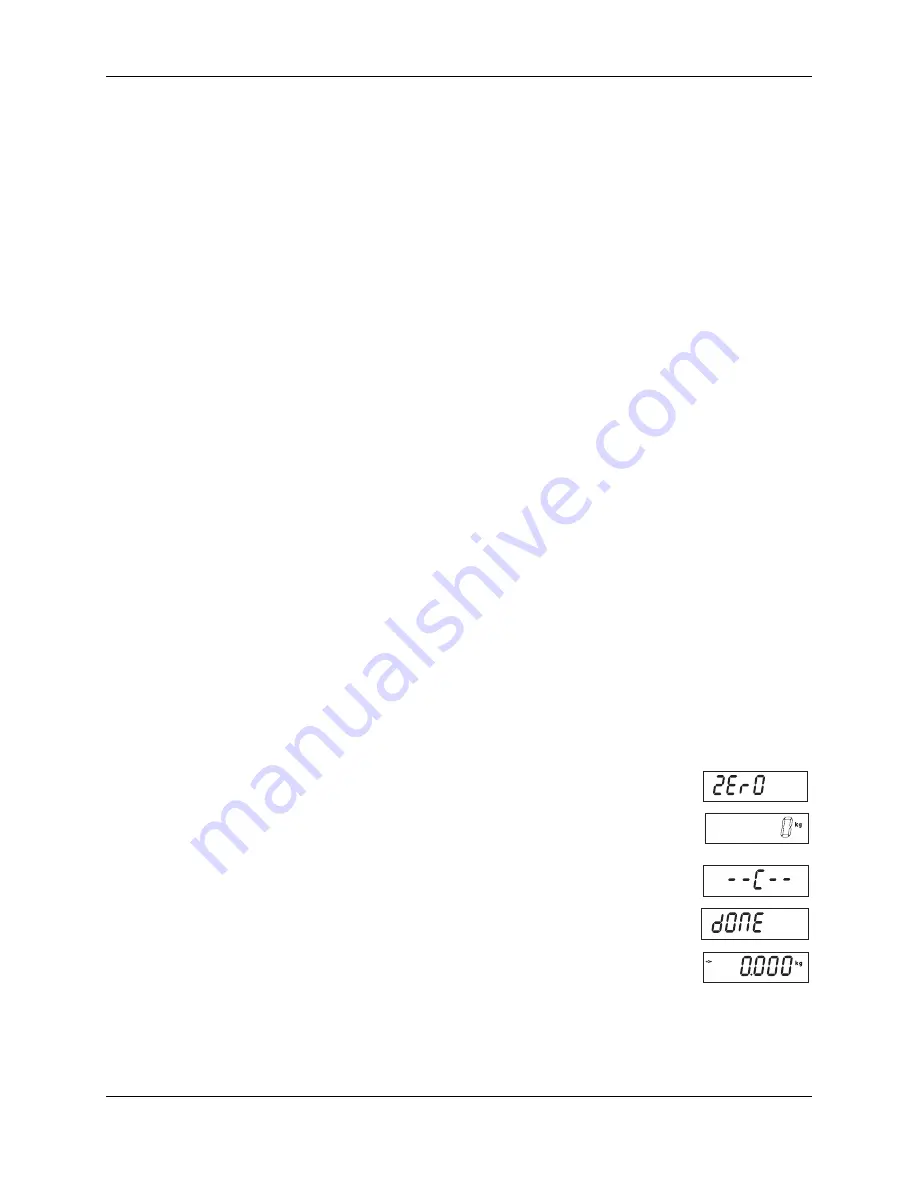

1.8.1 Zero

Calibration

Zero calibration uses one calibration point. The zero calibration point is established with no

weight on the scale. Use this calibration method to adjust for a different pre-load without

affecting the span or linearity calibration.

Press and hold

TARE/Menu

until

C.A.L.

appears, then press

Yes

.

(

LFt.NO

appears briefly before

C.A.L.

, if the Indicators is not in LFT mode.)

ZErO

appears. Press

Yes

to initiate Zero Calibration.

The display flashes

0

and the calibration unit. Press

Yes

to establish the

zero point.

The display shows

--C--

while the zero point is established.

When zero calibration is completed, the display shows

dONE

.

Then the scale exits to the active weighing mode and displays the actual

weight value.

Ohaus Corporation www.ohaus.com

1-10

5000 Series T51 Indicator Service Manual

Summary of Contents for T51P

Page 2: ......

Page 4: ......

Page 41: ......

Page 42: ... 80252587 P N 80252587 SERVICE MANUAL 5000 SERIES T51 INDICATORS ...