83

Appendix A - special applications

A-1 Sieve analysis

During most sieving operations, it is necessary to record the initial weight of each sieve before beginning as the

weights of the sieves may change due to particles being retained from the previous operation. In this procedure, the

basic sample is weighed first with its container weight tared

. This sample weight is entered into the balance

manually and stored during the procedure. Then, each sieve is weighed in sequence and the weights are stored. After

the screening process, each sieve along with its retained sample, is weighed in sequence. The balance stores the

weight values and automatically subtracts the weight of each sieve and displays the retained amount in a table as

percent retension. Up to 80 sieve weights can be stored.

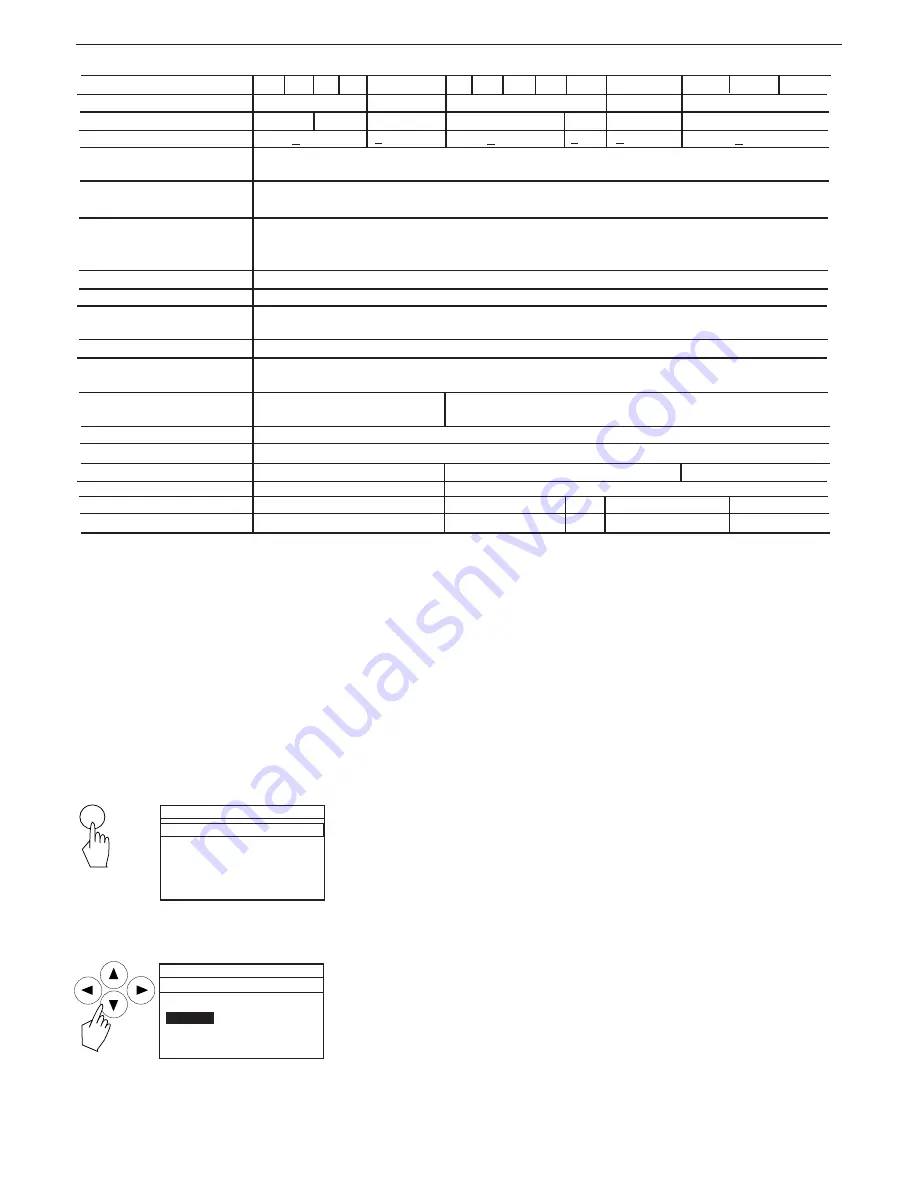

CHANGE MODE

Enter

From main menu

Enter CHANGE MODE and select DIFF WEIGHING, display advances to DIFF

WEIGHING SETUP with LIBRARY NAME highlighted.

DIFF WEIGHING

DIFF WEIGHING SETUP

LIBRARY NAME

Specify the library name

Specify the library name. The name can have any combination of alpha

numeric characters not to exceed 8 characters. After specifing the library

name, the display advances to DIFF STARTUP with SETUP highlighted. Press

the

Enter

button. The display advances to DIFF WEIGHING SETUP with TARE

SETUP highlighted.

DIFF4

Capacity (g)

210 410 510 610

100/410* 610 1500 2100 4100 6100 1000/4100* 4100** 6100** 8100**

Readability (g)

0.001

0.001/0.01

0.01

0.01/0.1 0.1

Repeatability (Std. dev.) (g) 0.0005 0.0015 0.0005/0.005 0.005 0.01 0.01/0.05

0.05

Linearity (g)

(+)0.002

(+)0.002/0.005

(+)0.02

(+)0.04

(+)0.02/0.05

(+)0.1

Weighing units***

gram, milligram, kilogram, pound, ounce, ounce troy, carat, pennyweight, Hong Kong Tael, Singapore

Tael, Taiwan Tael, mommes, grain, tical, Newton, custom

Application modes

Weighing, Parts Counting, Animal Weighing, Check Weighing, Percent Weighing, Filling, Gross-Net-

Tare Weighing

Features

RS232 Port, Auxillary Display Port, GLP Protocol, Selectable Language, Display Text, Selectable Displayed

Information Settings, Selectable Environmental Settings, Selectable Auto-Print Settings, Integral Weigh

Below Hook, Contrast and Brightness Control, Protective In-Use cover

Tare range

Full capacity by subtraction

Stabilization time (s)

3

Operating temperature range:

Non LFT w/internal calibration 10°C to 40°C / 50°F to 104° F

All others 10°C to 30°C / 50°F to 86°F

Calibration External / Internal

Power requirements

External Adapter, 100 -120 VAC 150mA, 220 - 240 VAC 100mA, 50/60 Hz

Plug configuration for US, Euro, UK, Japan & Australia

Draft shield (in/cm)

10.2/25.9

None

(free height above platform)

Display Type

LCD Dot Matrix w/CCFL Backlight

Display size (in/mm)

2.5 x 4.7 / 64 x 120

Pan size (in/cm)

4.7/12 Dia.

6.8 x 6.8/17.2 x 17.2 w/windshield 8 x 8/ 20.3 x 20.3 **

Dimensions (WxHxD) (in/cm) 8.5x13.5x14.5/21.5x35.5x37

8.5 x 4 x 14.5/21.5 x 10.1 x 37

Net Weight (lb/kg)

12.5 / 5.7

8.4 / 3.8 10/4.5

8.4 / 3.8

10 / 4.5

Net Weight (lb/kg) InCal Models

14.8 / 6.7

10 / 4.5 15.5/7

10 / 4.5

15.5 / 7

Precision Balances

* Moveable FineRange

TM

** Balances with Auto Cal are equipped with a 6.8 in. x 6.8 in. / 17.2 cm x 17.2 cm Pan and Windshield.

*** Units availability is country dependent.

Summary of Contents for Voyager V10640

Page 61: ...55...

Page 62: ...56...

Page 65: ...1 Ohaus Corporation 29 Hanover Road Florham Park NJ 07932 0900 Operating instructions balances...

Page 154: ...Operating instructions balances O T O T O T O T OHAUS...

Page 243: ......

Page 245: ......