45

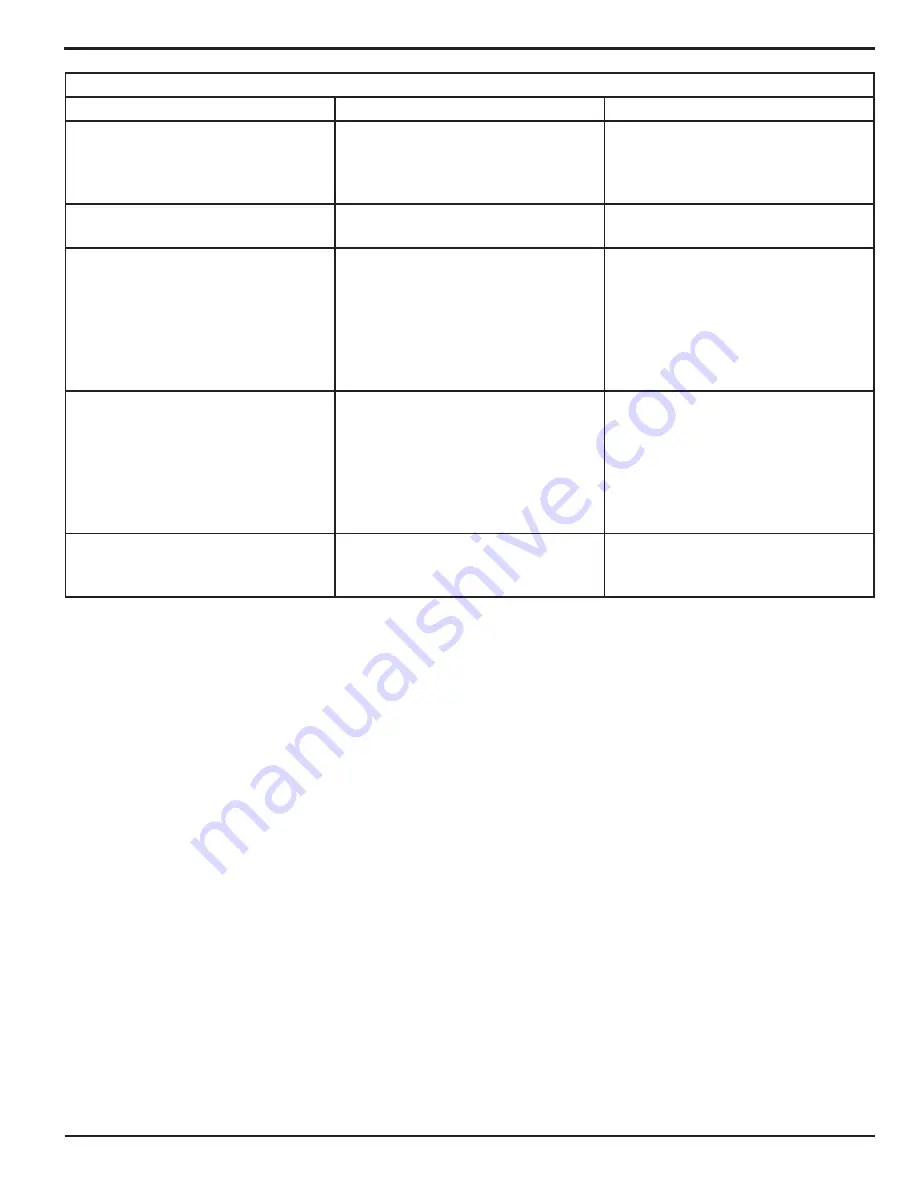

Inspection And Service Every Year or 12,000 Miles

Item

Inspection/Service

Manual Section Reference

Brakes, all types

•

Shoes and Drums

Check for scoring and wear. Replace

per manufacturer’s specifi cations.

Section 9.

See Brake Mfr’s Manual

Jack, Drop-leg (if equipped)

Grease gears at top.

See Jack Mfr’s Manual

Structure

•

Frame Members

•

Welds

Inspect all frame members, bolts &

rivets. Repair or replace damaged,

worn or broken parts.

Inspect all welds. Repair as

needed.

Section 9.

Section 9.

Wheels

•

Wheel Bearings

•

Rims

Disassemble / inspect / assemble

and repack. Replace promptly if

immersed in water.

Inspect for cracks & dents. Replace

as needed.

Section 9 & See Axle Mfr’s Manual

Structure

•

Axle Attachment Bolts

Check BY DEALER

Section 9.

Inspection, Service And Maintenance

Summary of Contents for Utility Trailer

Page 14: ...14 Safety ...

Page 52: ...52 ...