- 13 -

6

-2.

Timer Adjustment

Depending on actual shape of screws, delivery speed may be varied. It is recommended to adjust the timer setting longer for

screws with a slower delivery rate; and a shorter timer setting for smaller screws that move easily on the rail.

·- The screw delivery and vibration of this machine is designed to continue until

a screw is delivered, and the vibration shall stop after a certain time frame after

a screw is present. This time frame before the vibration stop is set by this Timer

volume. After the delivered screw is picked up, screw delivery operation r

esumes.

- Screw presence is detected by optical sensors.

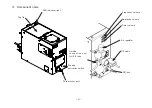

- The timer volume is shown as picture below (Third from the top)

- Turning the volume clockwise will make the timer shorter, and counter-clockwise

will make it longer.

ᰴᘧ♫ࠉṊ࣭࣮ࣝࢺᕤᴗ

ᅗ

␒

㸿㸱

ᢎ

ㄆ

᳨

ᅗ

〇

ᅗ

タ

ィ

ኚ᭦␒ྕ

ᖺ᭶᪥

ኚࠉ᭦ࠉグࠉ

ᢎㄆ

ኚ᭦⪅

సࠉᡂࠉᖺࠉ᭶ࠉ᪥

సᴗෆᐜ

〇ရྡ

㸦㒊ရྡ㸧

B

㸯㸳㹱

Timer adjusting knob

CW : Shorter

CCW : Longer

6

-3.

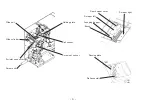

Adjustment of the air pressurizing speed

If the air pressure is set more than necessary amount, the screw

may bounce out from the output port. Or, when the pressure is

too low, the screw may not be delivered smoothly. Please make

fine adjustment according to actual conditions accordingly.

Adjustment is made with the acrylic panel removed.

When the feeder is in operation, pressure setting can be

adjusted by turning the actuator control as shown above. After

the adjustment is done, please fasten the fixing nut firmly.

CW : Less airflow

CCW: More airflow

Pressurizing speed controller