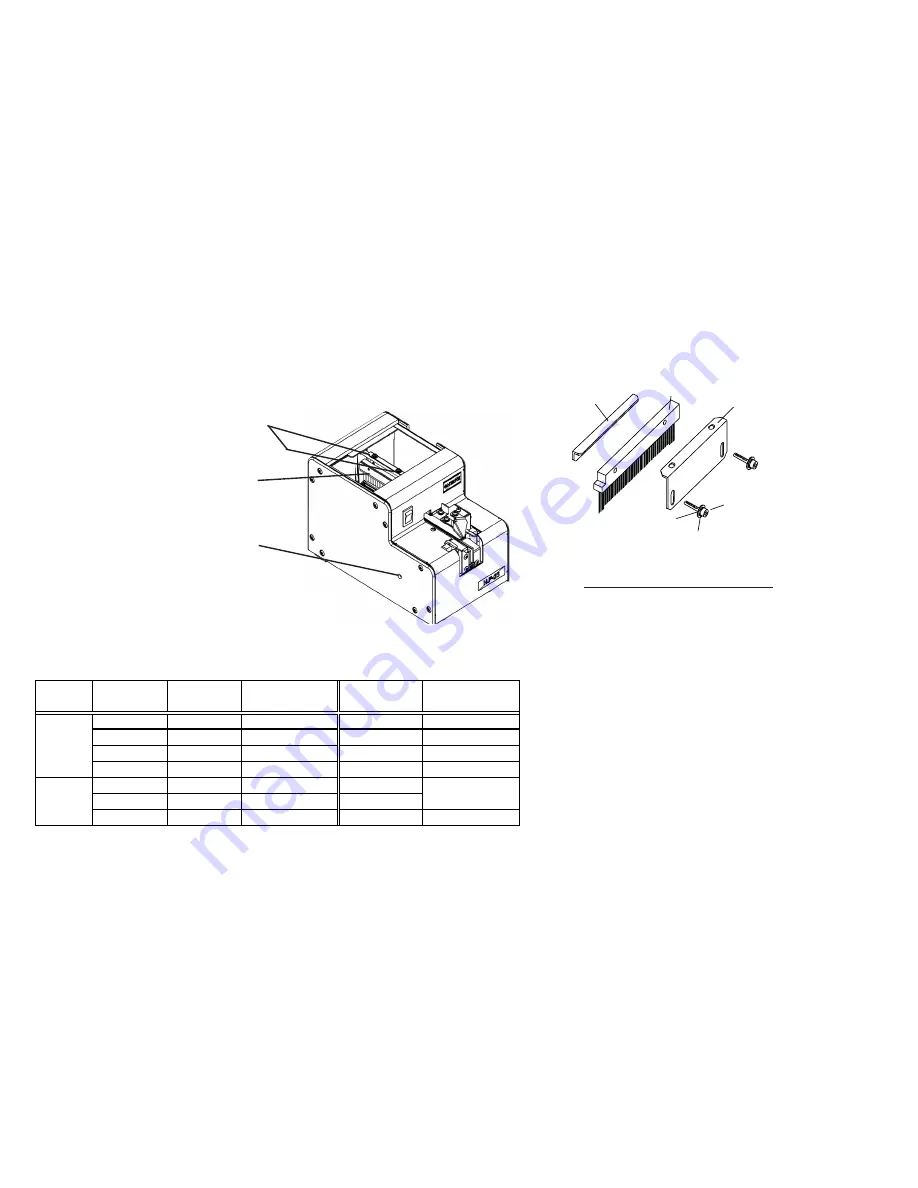

●Replacing the brush

If the ends of the brush bristles are worn out so that improperly oriented screws cannot be swept away, please replace the brush.

To replace the brush, please position it as shown below. You can also adjust its position by rotating the timing shaft.

Remove the brush assembly mounting screws and then the brush assembly. You can disassemble the brush assembly. After the

brush is replaced, install the brush assembly by reversing preceding steps.

All the above replacement parts are available as options. When they need replacement, contact your local dealer and specify the

machine model number, part names, and part model numbers.

-

15

-

Timing shaft

Brush assembly

Brush assembly mounting screws

Parts number

:

NJ02005a #02

Type

Model number Screw nominal

diameter

Exchange Kit

number

Rail model

number

Passage plate

model number

NJ-2320

φ2.0

R20SET

R20

W2320

NJ-2323

φ2.3

R23SET

R23

W2323

NJ-2326

φ2.6

R26SET

R26

W2326

NJ-2330

φ3.0

R30SET

R30

W2330

NJ-4535

φ3.5

R35SET

R35

NJ-4540

φ4.0

R40SET

R40

NJ-4550

φ5.0

R50SET

R50

W4550

NOTE: Replacement rails and passage plates are available as options.

In the Exchange Kit ordered separately, rails and passage plates are included.

W4540

NJ-23

NJ-45

NOTE 1: Different screw sizes may be applicable

with exchanging parts.

NOTE 2: To change the screw size (nominal

diameter), replace all the parts indicated at

left.

NOTE 3: The replacement rails, escapers, passage

plates, and brushes are available as

options.

Brush bracket 1

Brush bracket 2

Brush

Hex socket head

machine screw

M2.6x10

Spring washer

M2.6

Washer

M2.6

Brush assembly exploded view

Summary of Contents for NJ-2320

Page 25: ...Notes...