4

-

3

.

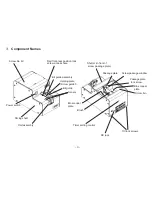

Checking and Adjusting the Passage Plate

-

6

-

Passage plate

Passage plate retaining screw

Up-down

adjustment

Employed

screw

Rail

Brush

Drop the employed screws into the rail groove. Slide the screws to the passage

window section and check or adjust the passage plate height. Check that the

clearance between the passage window upper end and the screw heads is not

greater than about 0.5 mm and that the screws can pass the passage window.

If the above requirements are not met, repeat above adjustment

procedures as needed.

After adjustment is completed, tighten the passage plate retaining screw. If the

screw applied has a relatively short shank, fine adjustments may be needed. For

screws having a relatively long shank, however, coarse adjustments will suffice.

Drop about 10 applied screws into the rail groove.

Tilt this machine or operate it so that the screws are delivered to the rail assembly

stopper.

If the shutter is closed or there is no clearance between the holding plate

(screw guide 1) and screw heads, the screws will not be able to move. The

screws can move when the shutter is open with an adequate clearance provided

between the holding plate (screw guide 1) and screw heads.

When the clearance is 0 to 1 mm, the holding plate (screw guide 1) height needs

no further adjustment.

NOTE: If the rail stopper captures a screw and brings the vibration to a stop

immediately, adjust the timer setting control on the rear side of the unit.

Holding plate(screw guide1)

Bit guide assembly

Stopper

Passage plate

Rail

Employed

screw

Approx.

0.5mm or less

Rail

Holding plate (screw guide 1)

Approx. 0 to 1mm

Employed screw

Bit guide

4

-

4

.

Checking and Adjusting the Holding Plate (Screw Guide 1)

Summary of Contents for NJ-2320

Page 25: ...Notes...