-

12

-

5- 6.

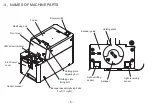

Check and adjust the front and rear sides of the rail

5- 7.

Check and adjust the rear hopper cover

Turn OFF the power switch before starting replacement and

adjustment.

Turn OFF the power switch before starting replacement and

adjustment.

Rail fixing bolt

Hold the rail groove and adjust the rail

assembly either backward or forward.

The rear hopper cover attaching bolts

The clearance between

the rear hopper cover and

the rail assembly is about

0.2mm

Scraper

・

If the rail comes into contact with the escaper, or the clearance between the

rail and escaper is too large, loosen the rail fixing bolt, hold the rail groove

and adjust the rail assembly either backward or forward. After making an

adjustment, be sure to tighten the rail fixing bolt.

・

When the rail comes in contact with the escaper, the escaper disk doesn't

rotate properly. When the clearance between the rail and the escaper is too

large, screws may fall down into the machine.

・

After making an adjustment, try making a vibration readjustment by referring

to " 5-4 Checking and Adjusting the Rail Vibration".

・

Check that the clearance between the rear hopper cover and the rail

assembly is about 0.2 mm.

・

If the rail hits against the rear hopper cover, the vibration will become weak

and the screws will be delivered slowly. If the rear hopper cover is too high,

the slit between the rail and the scraper catches screws easily.

・

If adjustment is required, loosen the rear hopper cover attaching bolts and

make an adjustment either up or down.

Summary of Contents for OM-26RB Series

Page 23: ...22...