© 2019 THE OILGEAR COMPANY - ALL RIGHTS RESERVED

Bulletin 948034A

11

Bulletin 948034A

PUMP SERVICE MANUAL

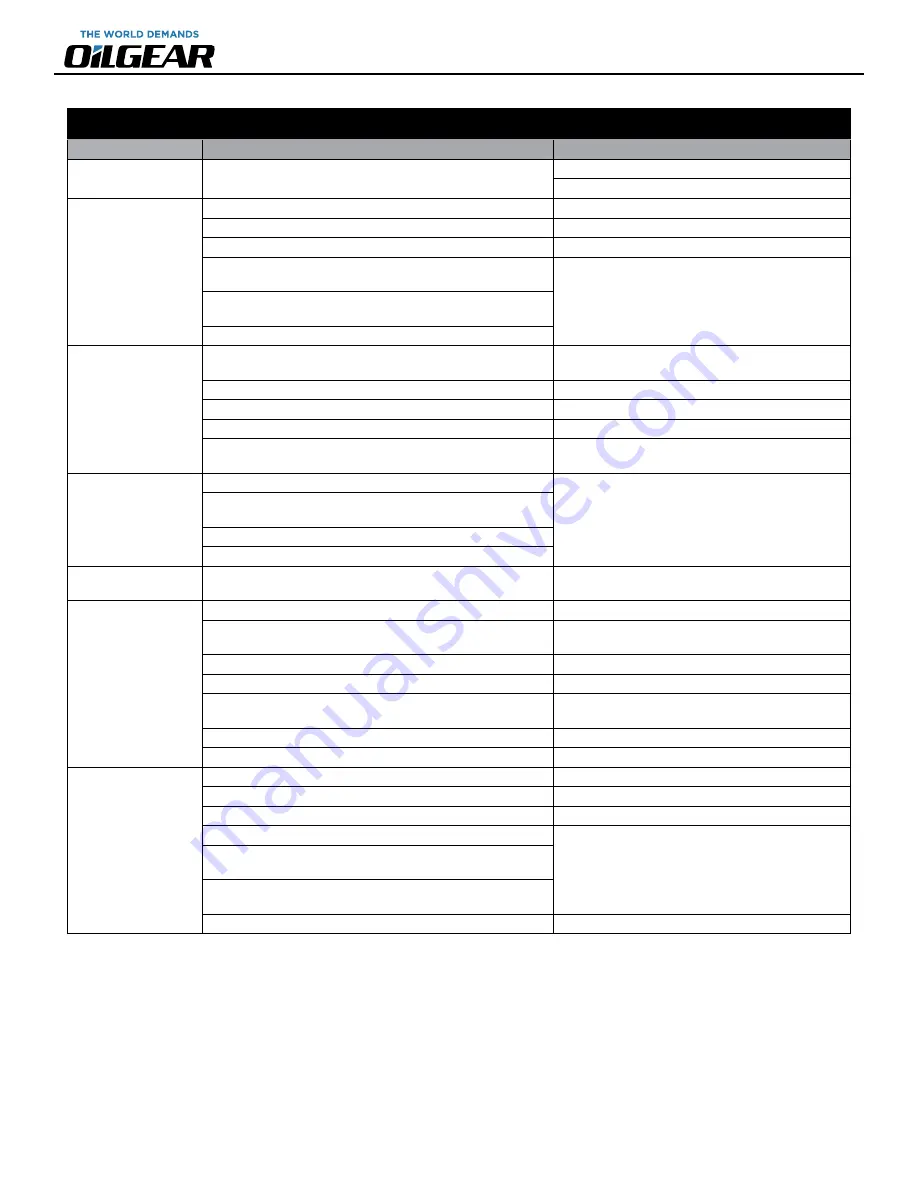

TROUBLESHOOTING

PROBLEM

CAUSES

REMEDY

Unresponsive or

Sluggish Control

Swashblock saddle bearings (204) worn or damaged.

Refer to referenced control instruction material.

Inspect bearings. Replace.

Insufficient Pump

Volume

.l

a

ir

e

t

a

m

n

o

it

c

u

rt

s

n

i

l

o

rt

n

o

c

e

t

a

ir

p

o

r

p

p

a

o

t

r

e

f

e

R

l

o

rt

n

o

c

y

tl

u

a

f

y

b

d

e

ti

m

il

y

r

e

v

il

e

D

Obstructed suction circuit or insufficient supercharge volume.

Inspect for obstruction and verify supercharge.

.l

a

ir

e

t

a

m

r

e

w

o

p

e

t

a

ir

p

o

r

p

p

a

o

t

r

e

f

e

R

.

d

e

e

p

s

r

o

t

o

m

e

v

ir

d

t

n

e

i

c

if

f

u

s

n

I

Worn or grooved cylinder barrel (101) and/or valve plate (401)

mating surfaces.

Inspect components. Replace.

Worn piston/shoe assemblies (102) or piston bores in cylinder

(101).

Worn or damaged piston shoe or swashblock (201).

Irregular or

Unsteady Operation

Faulty control.

Inspect components. Replace. Refer to referenced

pump control instruction materials.

Fluid level in reservoir is low or supercharge is insufficient.

Verify fluid level and/or supercharge.

Air entering hydraulic system

.

k

a

e

l

r

o

f

m

e

t

s

y

s

t

c

e

p

s

n

I

.

.

e

c

a

l

p

e

R

.

s

t

n

e

n

o

p

m

o

c

t

c

e

p

s

n

I

.

p

m

u

p

n

o

t

s

i

p

l

a

i

x

a

n

r

o

W

Faulty output circuit components (cylinder, motors, valves or

other related components).

Inspect components. Replace.

Loss of Pressure

Worn piston pump.

Inspect components. Replace.

Worn or grooved cylinder barrel (101) and/or valve plate (401)

mating surfaces.

Worn piston/shoe assemblies (102) or piston bores in cylinder.

Faulty output circuit components.

Excessive or High

Peak Pressure

.

s

e

v

l

a

v

f

e

il

e

r

e

h

t

k

c

e

h

C

.

s

t

n

e

n

o

p

m

o

c

t

i

u

c

ri

c

t

u

p

t

u

o

y

tl

u

a

F

Excessive Noise

Pump stopped or started incorrectly under load.

Verify operation procedure of pump.

Low fluid level in reservoir or insufficient supercharge causing

cavitation.

Verify fluid level and/or supercharge.

Air entering hydraulic system

.

k

a

e

l

r

o

f

m

e

t

s

y

s

t

c

e

p

s

n

I

.

Fluid too cold or viscosity too high.

Verify fluid temperature and/or type.

Suction line problem i.e.; obstructions in line, line too long, line

diameter too small or too many bends and/or loops in line.

Inspect line for obstruction.

Broken or worn piston/shoe assembly (102).

Inspect components. Replace.

.

p

m

u

p

f

o

n

o

it

c

e

ri

d

n

o

it

a

r

e

p

o

t

c

e

p

s

n

I

.

n

o

it

c

e

ri

d

g

n

o

r

w

n

i

g

n

it

a

t

o

r

p

m

u

P

Excessive Heating

Operating pump above rated or peak pressure.

Verify pump limitations.

Low fluid level in reservoir or insufficient supercharge.

Verify fluid level and/or supercharge.

Air entering hydraulic system.

Inspect system for leak.

Worn piston pump.

Inspect components. Replace.

Worn or grooved cylinder barrel (101) and/or valve plate (401)

mating surfaces.

Faulty output circuit components (continuous blowing relief valves

or "slip" through valves, cylinder or other components.

Insufficient cooling provision or clogged coolers.

Inspect for obstruction.