**An example of typical value adjustments:

1. If the room temperature is too cold when the outdoor temperature is −10 °C, slightly increase the flow

water setpoint at outdoor temperature points −13 °C and −7 °C.

2. Wait for at least two or three days to see if the change has made a difference.

3. Readjust the curve if necessary.

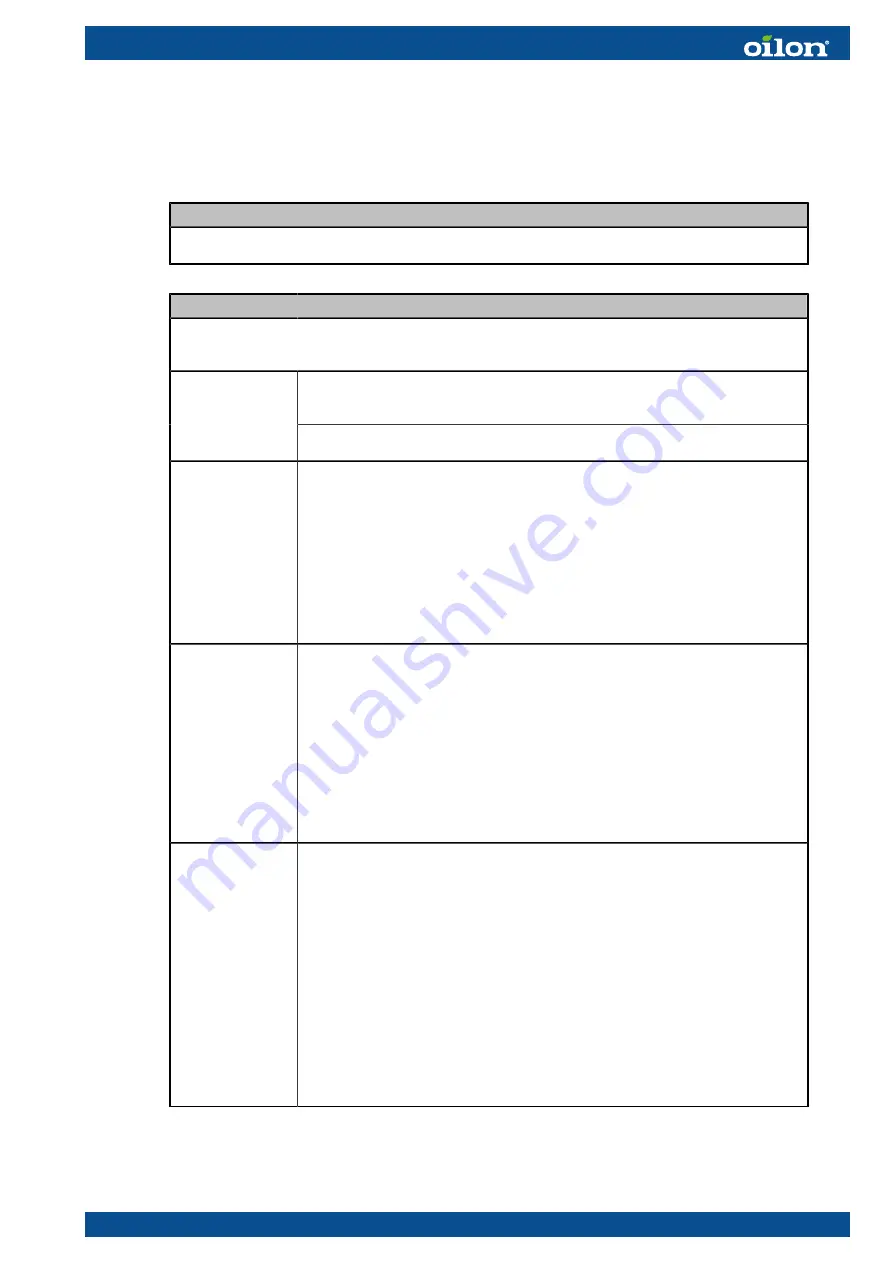

Heating circuit 2 and 3

See the instructions for heating circuit 1 setup. The circulation pump and control valve for heating circuit 2

and 3 require an auxiliary controller.

→ ADDITIONAL HEATING

An electric immersion heater (in-line heater) operates in the same manner as the compressor and uses

the same setpoint values. The heater switches on and off (and transitions between higher and lower

power stages) with a delay.

Internal electric heater

The condenser flow line includes an electric in-line heater.

ECO I: optional accessory

Additional heating

Not in use

The condenser circuit has no in-line heater (electric immersion heater).

Start delay with

compressor

The electric heater’s start delay in space heating. Once the delay has elapsed, the

first electric immersion heater power stage will be switched on.

● Increase the delay, if you wish to move forward the point at which the heater is

switched on (and starts to provide supplementary heating in parallel with the

compressor).

● Usually, the delay should be set to 120–600. The following power stages are

governed by the

Power increase delay

instead.

The delay is based on degree minutes, and it applies when the compressor is

running and the flow water temperature is below its setpoint. The delay is calculated

by subtracting the measured flow water temperature from the flow water setpoint.

Once the measured temperature is above the setpoint, the delay will be reset.

Power increase

delay

The electric heater’s power increase delay after the first power stage has been

activated. Once the delay has elapsed, the next electric heater power stage will be

switched on.

● Increase the delay, if you wish to move forward the point at which the next

power stages will be switched on to provide supplementary heating (in parallel

with the compressor and the first stage).

● Usually, the delay should be set to 40–120.

The delay is based on degree minutes, and it applies when the compressor

is running, the electric heater’s first power stage is active, and the flow water

temperature is below its setpoint. The delay is calculated by subtracting the

measured flow water temperature from the flow water setpoint. Once the measured

temperature is above the setpoint, the delay will be reset.

Power decrease

delay

The delay for switching off power stages. The last stage to have been activated will

be switched off first, the stage that was activated the second after the delay has

elapsed for a second time, and the first stage will be switched off when the delay

elapses for a third time.

● Decrease the delay, if you wish to have the power stages switch off earlier after

the flow water temperature exceeds its setpoint.

● If the delay is greater than 0, the heater power stages will remain switched

on even after the flow water temperature has exceeded the setpoint. Setting

the delay slightly above zero will usually result in a more stable flow water

temperature.

● Usually, the delay should be set to 0–2.

The delay is based on degree minutes, and it applies when the compressor is

running, the electric heater is active, and the flow water temperature is above

its setpoint. The delay is calculated by subtracting the measured flow water

temperature from the flow water setpoint. Once the measured temperature is below

the setpoint, the delay will be reset.

M8003 2219EN

31 (54)

Summary of Contents for ECO Inverter+ 7

Page 1: ...M8003 2219EN 24 May 2022 INSTALLATION AND COMMISSIONING ECO Inverter 7 25 ...

Page 2: ......

Page 4: ...6 7 EU Product Data 52 2 54 M8003 2219EN ...

Page 57: ......