Burner failure can also be reset by pressing burner failure reset button on the control

panel longer than 1 s, or by giving a remote reset signal.

Pressing of burner failure reset button during burner operation causes a

lockout. Button is also used as emergency stop button.

Fault history stores the last 21 error messages.

Scroll history data with the

Select -/+

buttons. To change the display from code display

to clear text and back, press

Enter

.

Lockout history stores the last 9 burner lockout indications. Lockout always causes

shutdown.

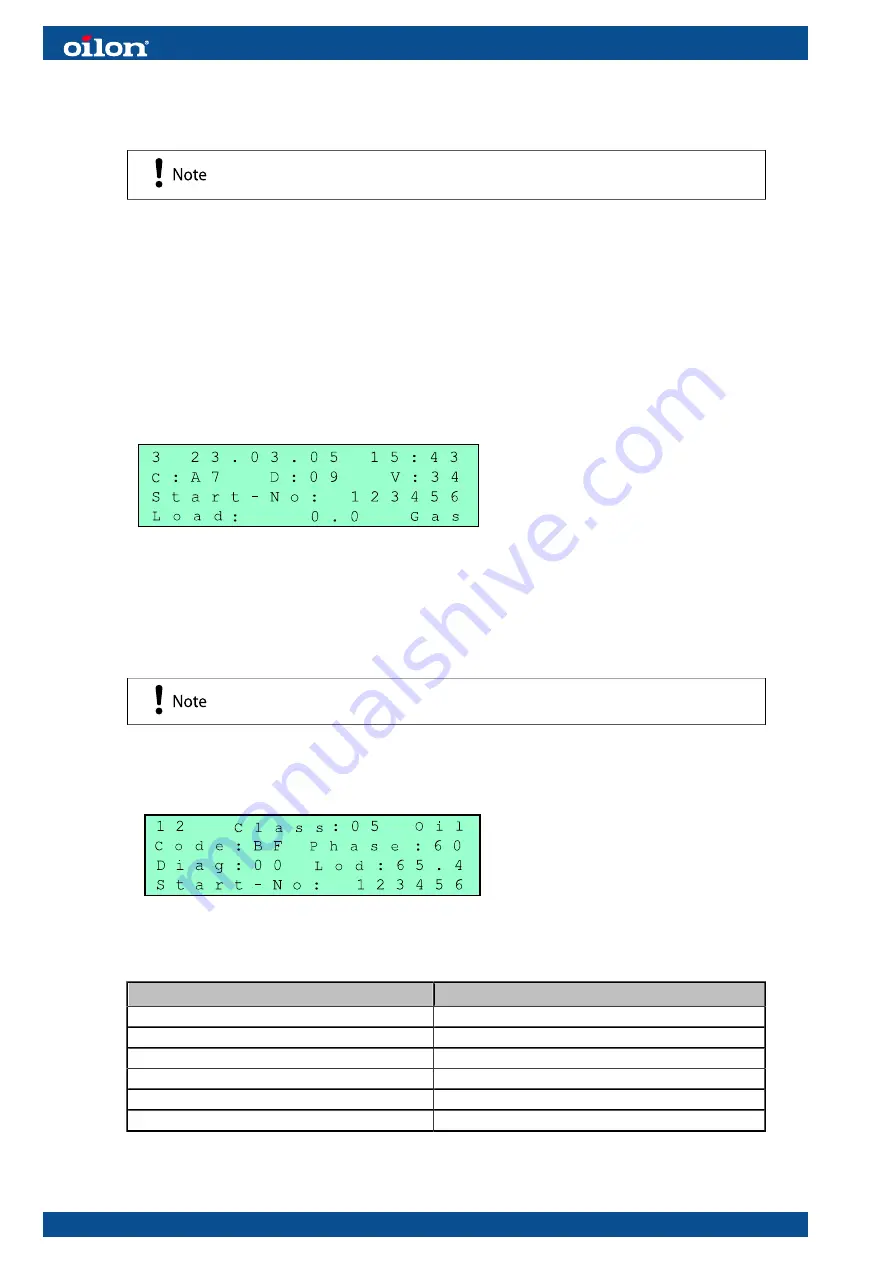

Burner manual lockout example

NAYTTO2 ver. 2

● 3. lockout in history

● Occurred 23.03.2005 at 15:43

● C = error code A7

● D = diagnostic code 09

● V = phase 34

● Start-No = start counter reading at the

time the fault occurred 123456

● Load = load at the time the fault occurred

0,0 %

● Gas = gas as fuel

Burner control can be reset immediately after shutdown. The servomotor runs to the

stand-by position after resetting, and the burner control allows a new burner start-up.

Shutdown means failure interlocking.

O

2

trim activation example for WD200

Point28 ver. 3

● 12. fault in history

● Class = 05, see the following table

● Oil = Oil as fuel

● Code = BF, error code

● Diag = 00, diagnostic code

● Phase = 60, phase

● Lod = 65.4%, load at the time the fault

occurred

● Start-No = start counter reading at the

time the fault occurred

Fault class

Description

00

Lockout

01

Safety reset

02

Safe mode

03

Home run

04

Control stop

05

Attention

120 (129)

M5178 1647EN

Summary of Contents for GKP-350 M

Page 2: ......

Page 5: ...6 15 Burner part list 129 M5178 1647EN 3 129...

Page 6: ...4 129 M5178 1647EN...

Page 18: ...Block diagram of contact links Block diagram ver 5 16 129 M5178 1647EN...

Page 100: ...5 5 Time sequence diagram gas use Time sequence diagram G ver 3 98 129 M5178 1647EN...

Page 101: ...Time sequence diagram Gp1 ver 5 M5178 1647EN 99 129...

Page 132: ...130 129 M5178 1647EN...

Page 133: ......