Point2 ver. 4

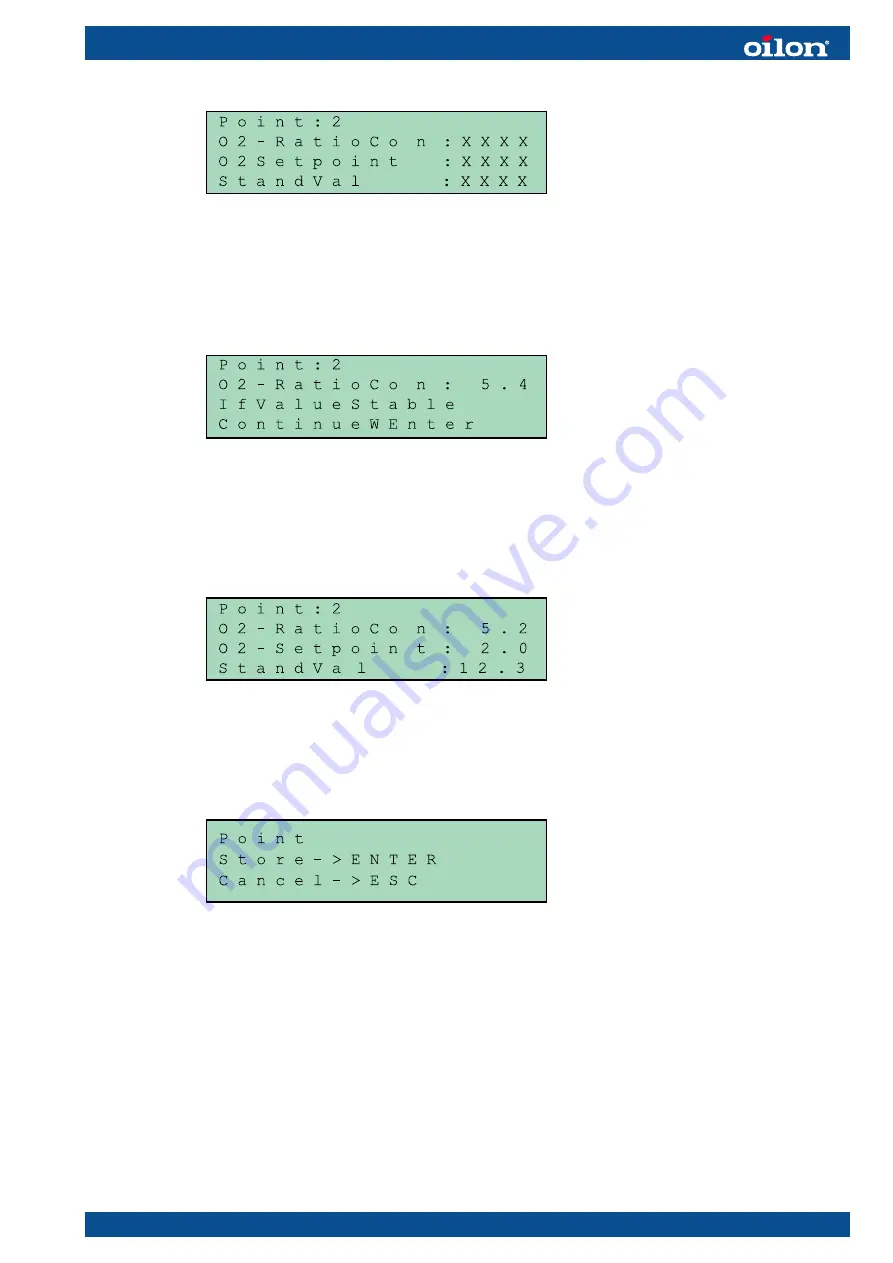

3. The display changes. The second line

O2ratioCon

shows current residual oxygen

level. Wait until the level stabilizes, and corresponds with ratio curve level. The

burner control uses this level when calculating O

2

trim control settings.

Confirm the selection by pressing

Enter

.

Point22 ver. 4

4. The display changes. The third line shows the current residual oxygen level. The

pointer is on

StandardVal

. Reduce the air by pressing the

Select -/+

buttons, if

necessary. A larger number at this point means larger without air throttle. When

desired oxygen level is reached, press

Enter

.

Point23 ver. 4

5. The display changes.

Save or reject by pressing

Enter or Esc

.

Point24 ver. 4

At curve point 2, and at the highest curve point, the burner control calculates PID

parameters, and time delays for O

2

monitor by driving the burner back to ratio

curve. After that the display returns to initial state.

Select next curve points from the menu by pressing the

Select -/+

buttons, and

set O

2

setpoints from them. If flue gas speed in ratio curve point 2 is too low, O

2

monitoring set value calculation does not succeed. The burner control notifies this in

the operating and display unit.

O

2

monitoring first point can be set later using the parameter

Adapt.Pointsmall

.

M4263 2206EN

63 (102)