If you want to set a new curve point, press

Enter

, when

XXXX

is displayed as the set

value.

The ignition position will automatically be set as the first ratio curve point, from which

the burner minimum load point is adapted.

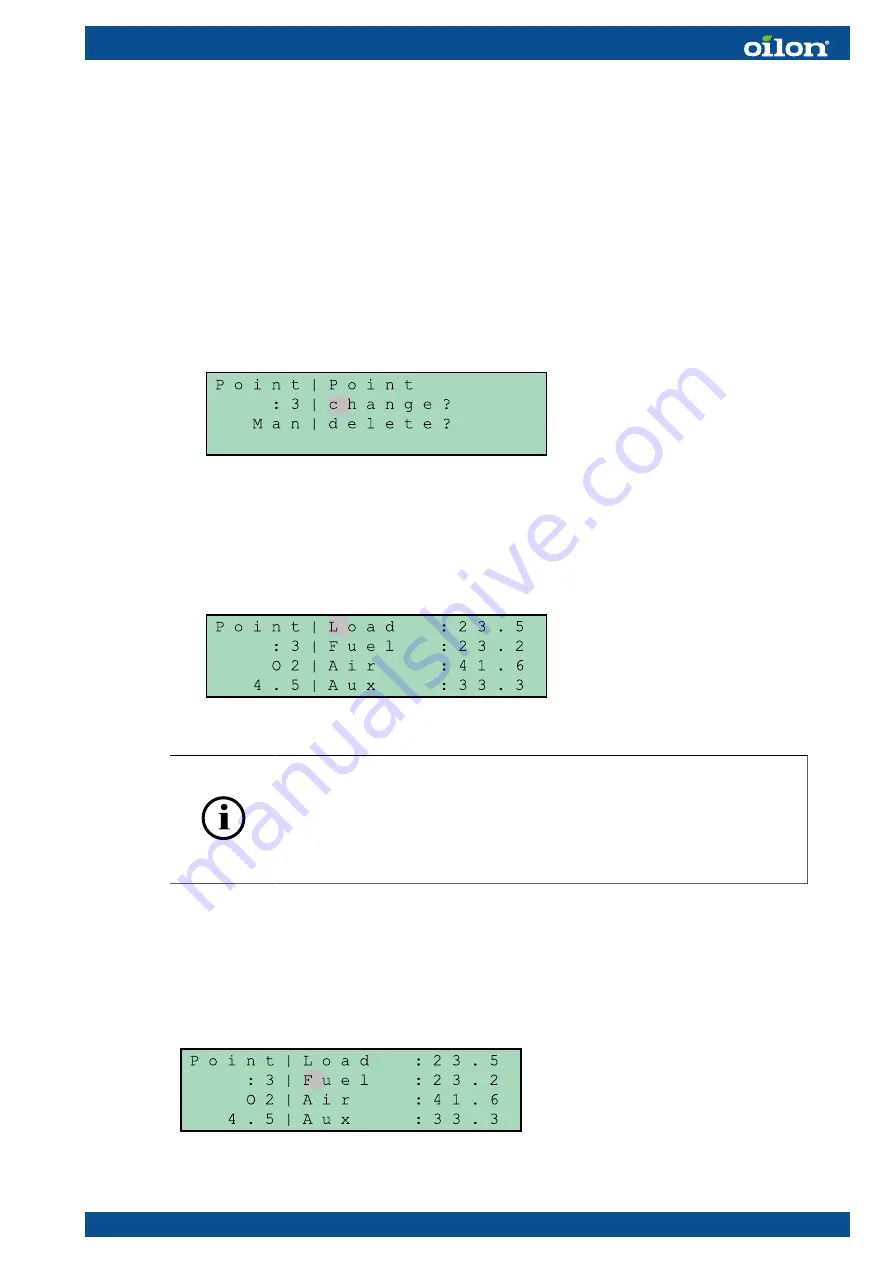

Editing individual curve point

To change an existing curve point:

1. Select the desired point and press

Enter

.

2. The pointer is positioned on

change?

below

Point

. The running number of the

curve point to be changed is displayed after the colon.

Curve point 3 ver. 4

3. Select the desired value using the

Select -/+

buttons, and press

Enter

.

●

change

changes the curve point settings

●

delete

deletes the curve point

Pointer positioned at

Load

.

Curve point 4 ver. 4

When the servomotors drive to position for a set curve point, the display

shows “>” instead of “:”.

When the servomotors have reached their positions, “:” returns to the

display.

Servomotor settings can be modified only when each servomotor has

reached its position.

This operation can be interrupted by pressing

Esc

. The display returns to its initial

state.

Capacity, servomotor and variable speed drive settings can be scrolled through using

the

Select -/+

buttons.

Curve point 5 ver. 4

M4219 2305EN

55 (111)

Summary of Contents for GP-600 M

Page 2: ......

Page 16: ...Block diagram of contact links Block diagram ver 7 14 111 M4219 2305EN...

Page 87: ...5 5 Time sequence diagram gas use 7550f57e 0515 Gp1 ver 6 M4219 2305EN 85 111...

Page 113: ...M4219 2305EN 111 111...

Page 114: ...112 111 M4219 2305EN...

Page 115: ......