p. 16

C) To control a motorised valve:

Many motorised valves have wires coloured BROWN and BLUE for power connections. In this

case BROWN goes to the terminal B2 under the heading BOILER and BLUE goes to the N

terminal of the master. Then a link from L (230V) to the terminals marked “Boiler B1”. The boiler

relay will be energised after a delay of 10 sec after the start of the main pump.

Basic versions without display. Type WLM2-1BA and WLM2-3BA The boiler relay will stop if

there is no heat demand measured by the Room sensors.

Versions with display. Type WLM2-1FS and WLM2-3FS.

These units have supply water temperature control, and the boiler relay will be ON once the

control valve has reached 20% open, and will remain on as long as a heat demand exists.

The master has an output for the underfloor circulating pump (secondary pump). The output will be

energised after a 180 sec. delay when any connected room sensor calls for heat. The delay is to

allow time for the thermal actuator to start opening.

The 230v AC pump can be connected directly to terminals L and N under the heading “Sec. UFH

Pump”. Connect the pump E (Earth) terminal to E (earth) on the master. The maximum pump load

must not exceed 4 amps , 230v at start up. There is an overrun period of 1 minute after the demand

for heat from the room sensor disappears.

Delay times:

Secondary UHF pump

180 sec.

X-output (configured as main pump) 190 sec.

Pump Output

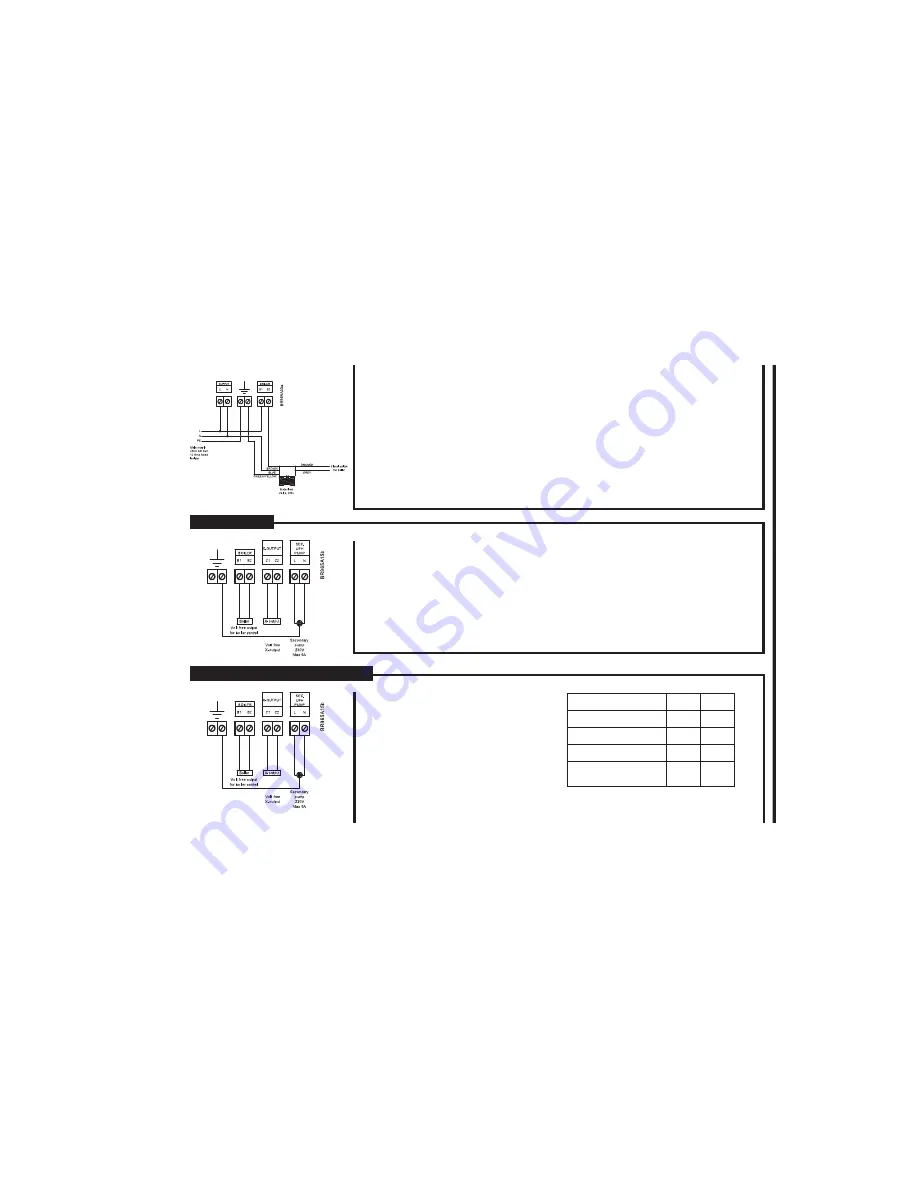

Free relay function (X-OUTPUT):

All WLM master have a relay which can be

utilized for a number of different purposes.

The relay is a volt free output and is positioned

on the PCB as shown on the drawing.

The function of the relay is determined by the

setting of the DIP-switches.

The functions that the relay can perform, and the

appropriate DIP-switch settings, are as follows:

To control:

Dip-5

Dip-6

Boiler pump

Off

Off

High limit zone valve*

On

Off

Cooling device/module**

Off

On

Cooling device/module

alternative

On

On

Fig. 5

Fig. 8a