Service Guide - C7000 Series

Chapter 8 Parts List

Page: 157

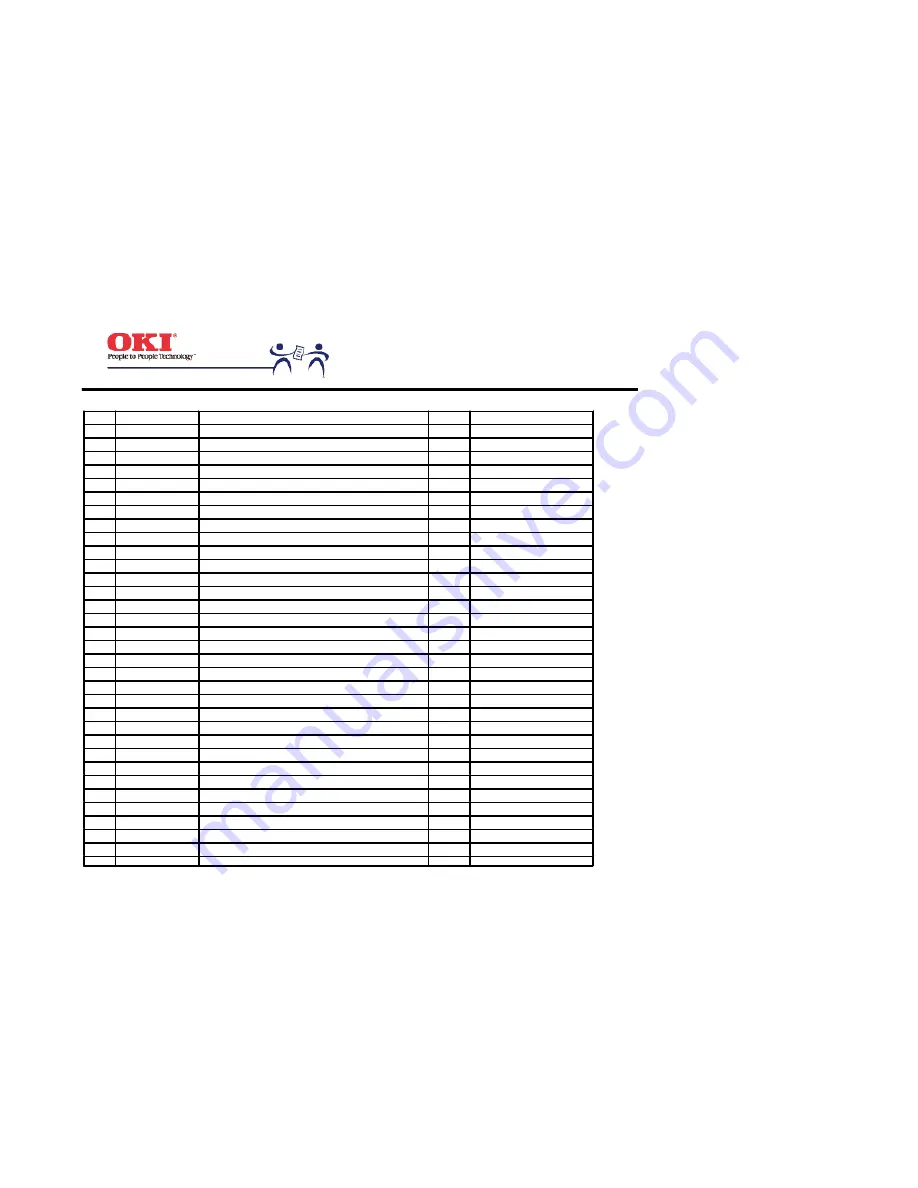

Main Assembly - Table 8-1 (1/3)

No.

Part #

Name

Qty

Remarks

1

40864601

Front Cover Assy

1

2

41042501

Front Cover Inner Baffle

1

3

40866701

Cassette Assy

1

4

41438401

Retard Pad Assy

1

5

1

6

40864301

Rear Cover

1

7

41374902

Face Up Stacker Assy

1

8

40864401

Left Side Cover

1

9

40864501

Right Side Cover

1

10

40862001

Multi-Purpose Tray Assy

1

11

40866301

Multi-Purpose Tray Cover Assy

1

12

41045801

Link

2

13

40325101

Multi-Purpose Tray Drive Gear

1

14

40952701

Multi-Purpose Tray Top Cover

1

15

16

17

18

41256204

Print Engine Controller PWB (71K)

1

1200 dpi

18

41256206

Print Engine Controller PWB (71K)

1

600 dpi

19

40197101

Electrical Chassis Cooling Fan

1

20

40864901

CRU Basket Assy

1

21

41275701

Upper Cover Open Switch

1

22

41439401

Retard Pad Assy Springs

2

23

Screw (T3x3)

14

24

Screw (M3x8)

2

25

Screw (M2x8)

2

26

EEPROM

1

27

28

Screw (T3x10)

13

29

Screw (M3x6)

42

30

41304001

Fuser - Unit 120V

1

120V

30

41304003

Fuser - Unit 230V

1

230V

Summary of Contents for C7200

Page 9: ......

Page 10: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 12: ......

Page 13: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 19: ......

Page 20: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 22: ......

Page 25: ...Service Guide C7000 Series Chapter 2 Operation Page 8 2 2 Engine Controller Board K71 PWB...

Page 26: ......

Page 30: ......

Page 31: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 42: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 44: ......

Page 45: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 47: ......

Page 48: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 51: ......

Page 52: ......

Page 53: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 55: ......

Page 56: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 58: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 67: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 69: ......

Page 70: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 77: ......

Page 78: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 85: ...Service Guide C7000 Series Chapter 3 Disassembly Page 43 3 2 Parts Layout...

Page 86: ......

Page 88: ...Service Guide C7000 Series Chapter 3 Disassembly Page 44 Top Cover Assy...

Page 89: ......

Page 90: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 91: ...Service Guide C7000 Series Chapter 3 Disassembly Page 45 Printer Unit Printer Unit 1 2...

Page 92: ......

Page 93: ...Printer Unit 2 2...

Page 94: ......

Page 95: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 96: ...Service Guide C7000 Series Chapter 3 Disassembly Page 46 Cassette Guide Assy L R...

Page 97: ......

Page 98: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 99: ...Service Guide C7000 Series Chapter 3 Disassembly Page 47 Duplex Unit...

Page 100: ......

Page 101: ......

Page 107: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 109: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 110: ......

Page 112: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 114: ......

Page 115: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 117: ......

Page 118: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 120: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 122: ......

Page 123: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 125: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 127: ......

Page 129: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 131: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 133: ......

Page 134: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 136: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 138: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 140: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 142: ......

Page 143: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 145: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 147: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 149: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 150: ......

Page 152: ......

Page 153: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 155: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 158: ......

Page 159: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 161: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 163: ......

Page 165: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 167: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 168: ......

Page 170: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 171: ......

Page 173: ......

Page 174: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 176: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 177: ......

Page 179: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 181: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 183: ......

Page 184: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 186: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 188: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 190: ......

Page 191: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 193: ......

Page 194: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 196: ......

Page 197: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 199: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 200: ......

Page 203: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 206: ......

Page 208: ......

Page 209: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 211: ...3 Removing the CRM Board...

Page 213: ......

Page 214: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 218: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 225: ......

Page 226: ......

Page 227: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 234: ......

Page 235: ......

Page 240: ......

Page 250: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 257: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 274: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 276: ......

Page 277: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 280: ......

Page 281: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 283: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 284: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 135 2 3 Paper feed jam...

Page 285: ......

Page 286: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 287: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 136 2 4 Paper Exit Jam...

Page 288: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 289: ......

Page 290: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 137 2 5 Duplex Jam...

Page 291: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 292: ......

Page 293: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 138 3 Paper Size Error...

Page 294: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 295: ......

Page 297: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 140 5 Fusing Unit Error...

Page 298: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 303: ......

Page 304: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 306: ......

Page 307: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 309: ......

Page 310: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 312: ......

Page 314: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 316: ......

Page 317: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 319: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 150 8 Missing Image...

Page 320: ......

Page 321: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 322: ...Service Guide C7000 Series Chapter 6 Troubleshooting Procedures Page 151 9 Color Misalignment...

Page 323: ......

Page 324: ......

Page 325: ......

Page 326: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 328: ......

Page 329: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 331: ...Service Guide C7000 Series Chapter 7 Wiring Diagram Page 154 7 1 Resistance Check...

Page 332: ......

Page 333: ......

Page 334: ......

Page 335: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 336: ......

Page 338: ......

Page 339: ...2 Main Controller PWB...

Page 340: ......

Page 342: ...5 Control Panel PWB X71 PWB 6 N71 PWB 7 Entrance Sensor PWB R71 PWB...

Page 343: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 344: ...Service Guide C7000 Series Chapter 8 Parts List Page 156 Main Assembly Figure 8 2...

Page 345: ......

Page 346: ...Figure 8 1 1 3...

Page 347: ......

Page 350: ...31 41303901 Belt Unit 1 Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 353: ...Service Guide C7000 Series Chapter 8 Parts List Page 160 Top Cover Assembly Figure 8 2...

Page 354: ......

Page 355: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 357: ...Service Guide C7000 Series Chapter 8 Parts List Page 162 Printer Unit Chassis Figure 8 3...

Page 358: ......

Page 359: ......

Page 360: ......

Page 361: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 364: ...Service Guide C7000 Series Chapter 8 Parts List Page 164 Paper Tray Guide Figure 8 4...

Page 365: ......

Page 366: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 368: ...Service Guide C7000 Series Chapter 8 Parts List Page 166 Duplex Unit Figure 8 5...

Page 369: ......

Page 370: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 373: ......

Page 375: ...b On line off line switching timing by ON LINE SW c Off line on line switching by ON LINE SW...

Page 379: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 381: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 383: ......

Page 384: ...Copyright 1999 Okidata Division of OKI America Inc All rights reserved...

Page 386: ......

Page 387: ......