7

© 2012 OKI DATA CORPORATION All rights reserved

ES9160 MFP / ES9170 MFP

PREVENTIVE MAINTENANCE (PM)

7 - 33

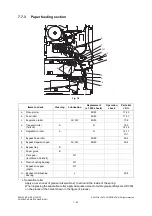

7.7.11

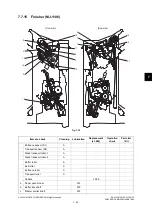

RADF (MR-3022)

Fig. 7-24

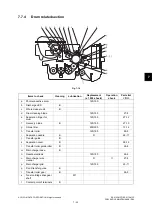

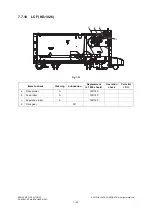

7.7.12

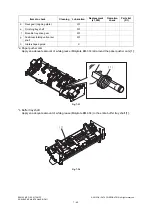

Finisher (MJ-1032)

Items to check

Cleaning

Lubrication/

Coating

Replacement

(x 1,000 sheets)

Operation

check

Parts list

<P-I>

a

Pickup roller

A

120

5-1

b

Separation roller

A

120

4-10

c

Feed roller

A

120

5-1

d

Registration roller

A

e

Intermediate transfer

roller

A

f

Front read roller

A

g

Rear read roller

A

h

Reverse registration

roller

A

i

Exit/reverse roller

A

j

Platen sheet

A or B

Item

Interval

Description

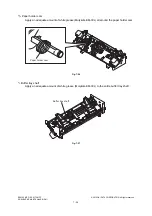

î€çl

Transport roller

Every 30,000 of paper feeding times

Cleaning

Wipe with a

cloth soaked in

water and then

tightly

squeezed.

Small roller in the paper

transport section

Transport path and

guides

Transport path sensor

Wipe with a dry cloth.

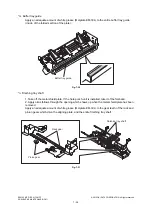

Grease application to

drive unit

As needed

Applying

grease

EM-50L

Paper detection sensor

Minimum maintenance interval set

for the equipment

Cleaning

Wipe with a dry cloth or alco-

hol

a

c

g

d

b

f

e

h

i

j

Summary of Contents for ES9160

Page 12: ......

Page 24: ...ES9160 MFP ES9170 MFP 2012 OKI DATA CORPORATION All rights reserved FEATURES 1 2...

Page 308: ...ES9160 MFP ES9170 MFP 2012 OKI DATA CORPORATION All rights reserved SELF DIAGNOSIS MODES 5 56...

Page 832: ...ES9160 MFP ES9170 MFP 2012 OKI DATA CORPORATION All rights reserved REMOTE SERVICE 10 38...

Page 920: ...ES9160 MFP ES9170 MFP 2012 OKI DATA CORPORATION All rights reserved BACKUP FUNCTION 12 12...

Page 1086: ......

Page 1087: ......