41057610TH Rev. 1

173 /

Appendix A

CENTRONICS PARALLEL INTERFACE

1)

Connector

•

Printer side

: 36-pin receptacle (Female)

Type 57RE-40360-830B-D29 (made by Daiichi Denshi) or equivalent

•

Cable side

: 36-pin plug (Male)

Type 57-30360 (made by Daiichi Denshi) or equivalent

Plug-552274-1 (AMP), 552073-1 (AMP) or equivalent

2)

Cable

•

Cable length : 6 ft (1.8 m) max.

(A Shielded cable composed of twisted pair wires is recommended for noise prevention.)

Note: Cable is not supplied.

Summary of Contents for OKICOLOR 8

Page 2: ...OKICOLOR 8 Color LED Page Printer Maintenance Manual 1999 7 14 Rev 1...

Page 12: ...41057610TH Rev 1 11 This page intentionally left blank...

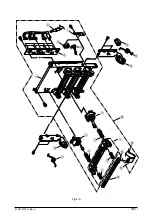

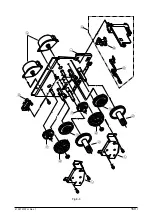

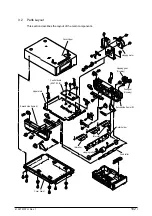

Page 44: ...41057610TH Rev 1 43 Figure 3 1 3 2 Parts Layout...

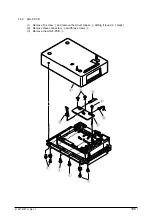

Page 45: ...41057610TH Rev 1 44 Figure 3 2...

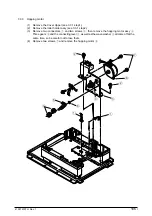

Page 46: ...41057610TH Rev 1 45 Figure 3 3...

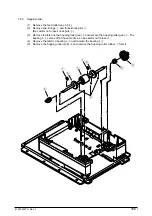

Page 47: ...41057610TH Rev 1 46 Figure 3 4...

Page 105: ...41057610TH Rev 1 104 olor check pattern...

Page 156: ...41057610TH Rev 1 155 Fig 8 2 2 1 O 3 N C 0 9 Q 6 M J 8 7 8 S H E 7 K G 4 P D R L B A F T 5...

Page 166: ...41057610TH Rev 1 165 Fig 8 6 H B E F 2 J 4 4 I 3 3 6 9 8 7 G C D A 0 5 1 5...

Page 168: ...41057610TH Rev 1 167 Fig 8 7 1 2 5 6 3 4...

Page 170: ...41057610TH Rev 1 169 Fig 8 8 7 7 5 A 5 6 6 3 3 4 4 0 9 1 8 2...

Page 172: ...41057610TH Rev 1 171 Fig 8 9 7 6 6 5 5 4 1 8 8 2 3 4 3 7...

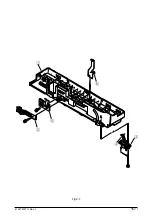

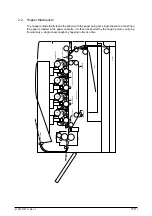

Page 196: ...41057610TH Rev 1 195 SEN1 CN22 CN23 CN24 5 2 PCB Layout AOLT PCB...

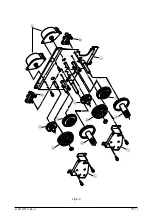

Page 197: ...41057610TH Rev 1 196 6 PARTS LIST 4 D 9 3 B 6 C A E F 2 J I L 0 1 K G G G 5 7 H 9 8...