User’s Guide

29

English

Put the drum cartridges where they will not be scratched

and not exposed to strong light.

3.

Inspect the paper path for sheets of paper. Carefully remove

any sheets (2) you find.

Paper jammed under the first image drum should be pulled

forwards through the paper path if possible, not backwards,

to avoid spillage of unfused toner into the paper input

area.

Be especially careful not to scratch the transfer belt. Avoid

using sharp instruments.

4.

Lower each image drum cartridge back into position via its

two locating slots at each side of the printer, being careful

to match the coloured label on each cartridge with its

corresponding coloured label in the printer.

5.

Close the top cover and press down firmly at both sides to

ensure that it is locked down.

Clearing a Paper Exit Jam

An indicated paper exit jam means paper has jammed in the

fuser or between the fuser and the point of exit from the printer.

1.

Press the OPEN button and raise the top cover to its fully

upright position.

When accessing the central area take care not to touch

the hot surfaces around the fuser. These are clearly

marked with yellow warning labels, and are very hot.

2.

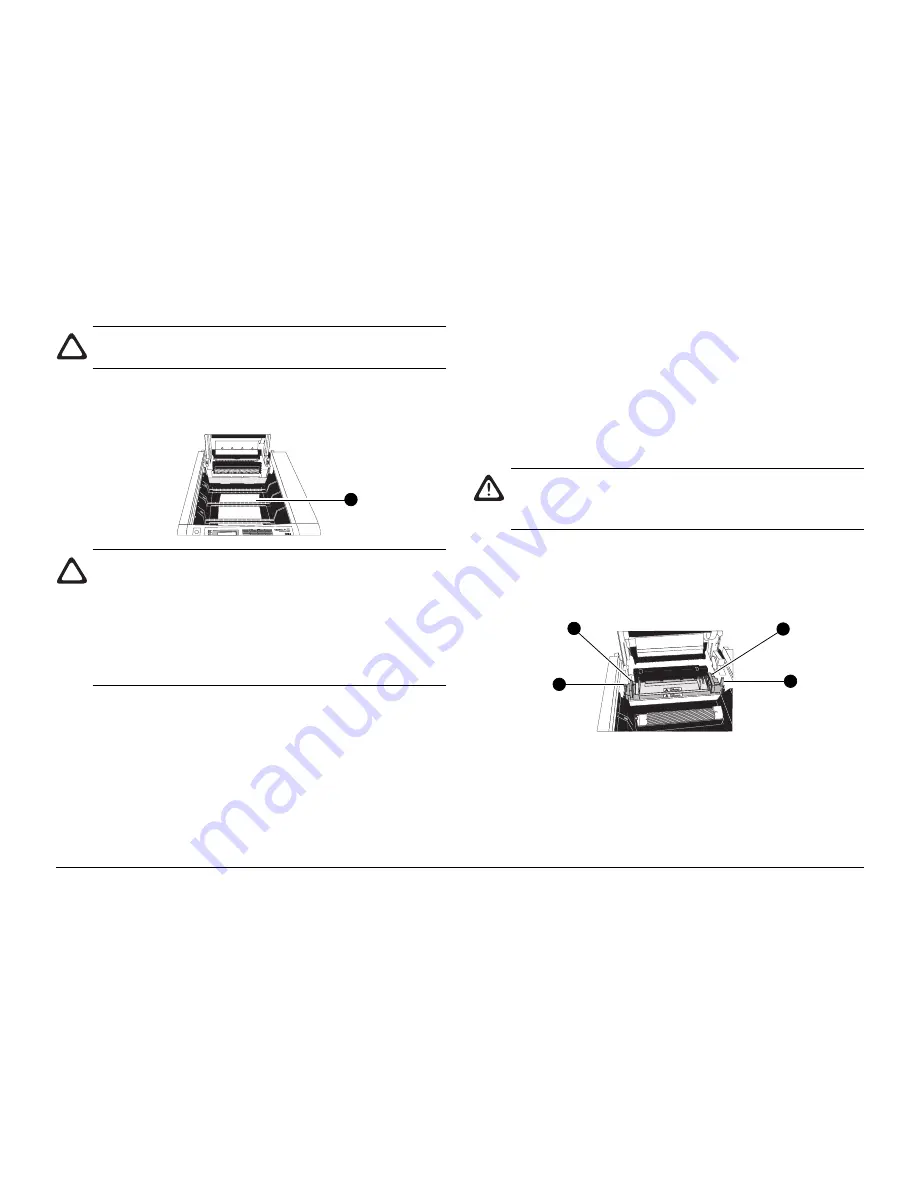

Push the two coloured fuser latch levers (1) away from you

(towards the rear of the printer).

3.

Lift the fuser by its two handles (2) straight up and out of

the printer.

2

1

2

2

1

Summary of Contents for OKIPAGE 8c Plus

Page 1: ...User s Guide...