- 55 -

• Do not use the following types of paper. Otherwise poor printing may be caused or the machine may

malfunction.

Paper whose end face of the roll is not cut clearly

Paper joint with tape in the middle of the roll

Paper taped or glued onto the winding core

Labels without liner or with exposed glue on the back

Paper with labels easy to peel off or peeled off

Paper with glue from the label exposed to the liner or adhering to the label surface

Paper with holes (excluding holes for cutting position detection)

Paper with cuts (excluding notches for cutting position detection)

Paper with perforations

Paper with different label sizes within one roll

Paper with different paper widths within one roll

Media of which both the liner and label are transparent

Continuous paper which is transparent

Metal foil media or conductive paper

Inkjet paper/label

Continuous labels

Paper with oozing glue on the liner

Paper with smooth surface, rough paper, and paper with different front and back roughness

Paper that is too thin or too thick, or with too much paper dust

Wet (damp) paper

Paper stuck by static electricity

Paper whose surface has been textured, embossed and coated

Paper which has been specially processed with glue, chemicals, etc. on the surface or specially processed

without heat resistance

Paper which has irregularities, crushing, burrs, etc. on the paper cut surface

Non-square shaped paper, or paper whose cutting angle is not right

Paper with wrinkles, warps, corner bending, waves, creases, tears, etc.

Paper with staples, clips, ribbons, tapes, clasps, etc.

Special paper such as carbon paper, non-carbon paper, thermal paper, and pressure-sensitive paper

Thermal transfer printer paper, wet PPC paper, Japanese paper, copying paper, inkjet paper, etc.

Paper mixed with paper strips

Note 1) For thick paper, the toner may stick thinly to the whole paper or the printing may be light.

Note 2) If the paper grain direction does not match the paper feeding direction, a paper jam may occur.

Note 3) Do not use paper that has been printed once with an electronic printer, thermal transfer printer,

inkjet printer, etc.

Note 4) Since the orientation of the surface is indicated on the wrapper of the paper, load the paper with the

printing side on the front.

Note 5) The paper is packed with moisture-proof paper to prevent moisture, so use it up as soon as possible

after unpacking.

Note 6) If paper strips (including die-cut paper strips) or paper dust gets inside the printer, it may cause poor

printing, malfunction or errors.

•

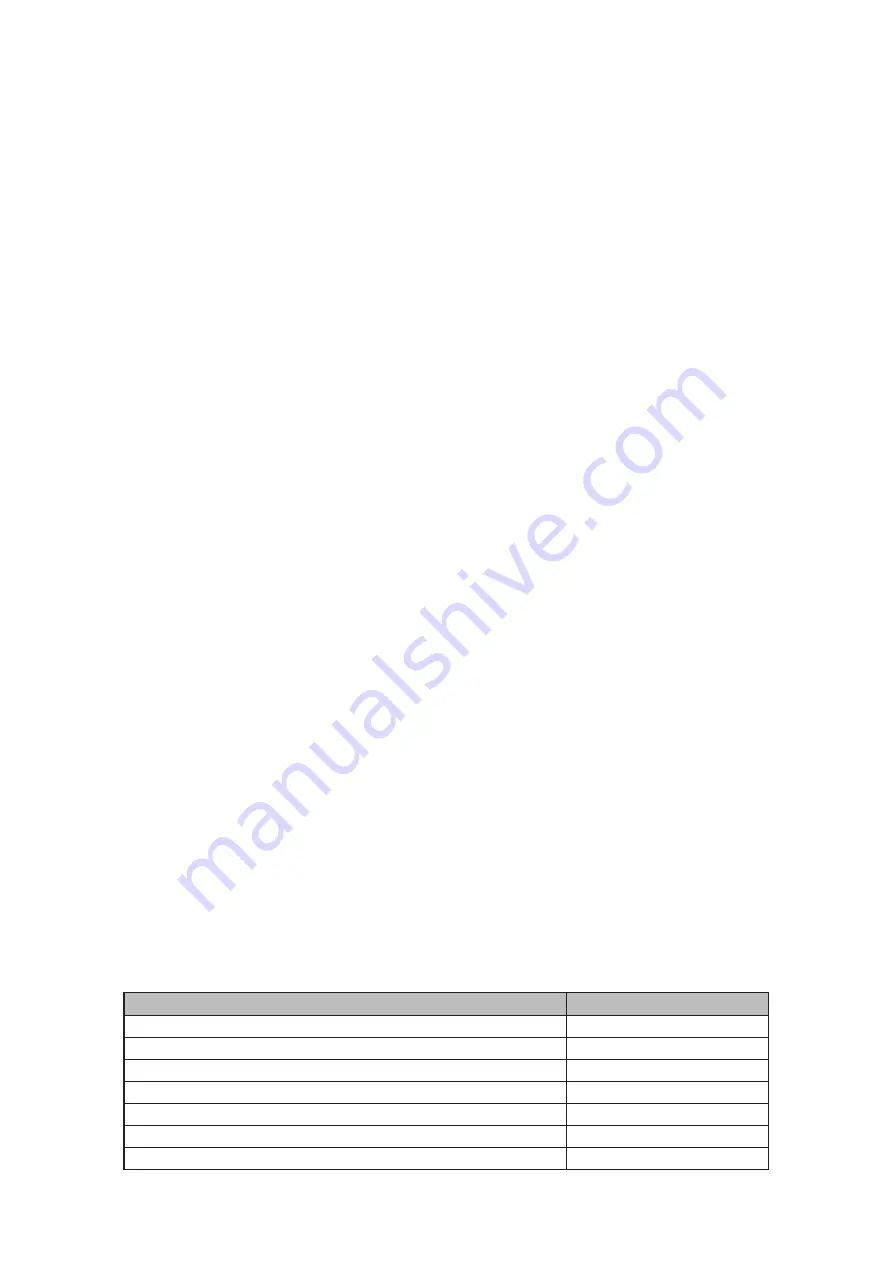

Setting the paper weight

Please set the paper weight in the printer or the printer driver according to the thickness of the

paper to be used.

Paper thickness (including the thickness of the liner)

Paper weight settings

60 - 69 μm

Light

70 - 102 μm

Medium Light

103 - 129 μm

Medium

130 - 164 μm

Medium Heavy

165 - 194 μm

Heavy

195 - 219 μm

Ultra Heavy 1

220 - 250 μm

Ultra Heavy 2

Summary of Contents for PRO330S

Page 1: ...Pro330S Label Printing Manual ...

Page 19: ... 19 Shaft x1 Ground pin Roll Paper Holder Setup Guide ...

Page 90: ... 90 7 Install the image drum back to the machine 8 Close the top cover ...

Page 94: ... 94 10 Install the image drum back to the machine 11 Close the top cover ...

Page 110: ...7 Cleaning 111 Cleaning the roll paper holder 112 Cleaning the main unit 115 Maintenance ...

Page 122: ... 122 20 Close the top cover ...

Page 140: ...EE8001 5120Z002 Rev3 ...