EM1401 / EM1401 UT EMA Thickness Gauge. Operation Manual.

+7(812) 385-54-28

info@oktanta-ndt.ru

46

Calibration Test Procedure

During the calibration test, the following operations should be performed:

1.

External examination;

2.

Functional test;

3.

Measurement error calculation.

In agreement with the bodies conducting the Device calibration test, the

calibration test may be performed not in full.

Calibration Instruments

The calibration instruments shall have valid Calibration Test Certificates or

marks.

The calibration test is performed using the following test samples:

1.

A КУСОТ-180 set of standard samples of the equivalent ultrasonic

thickness or a КМТ-176М-1 (КМТС-97) set of ultrasonic thickness control gauges;

2.

A set of plane-parallel samples made of one steel blank with the following

parameters:

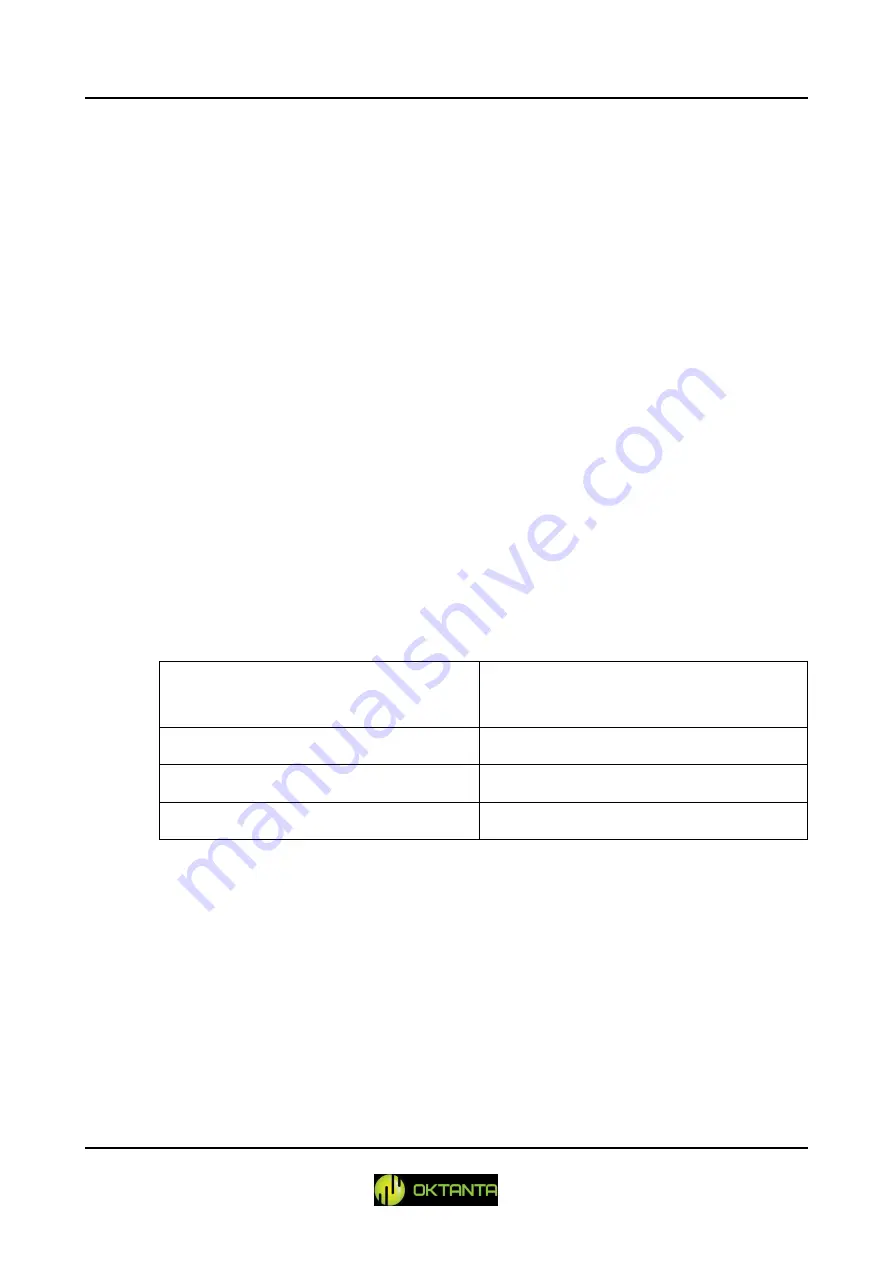

Thickness, mm

Roughness RZ, micron, less

than

2 ± 0.01

10

10 ± 0.015

20

60 ± 0.03

20

The calibration instruments can differ from those mentioned above but their

characteristics must not be inferior to those mentioned above and must be sufficient to

obtain a reliable result. The use of such calibration instruments must be agreed with

the Gosstandart bodies

Calibration Test Conditions

The calibration test shall be performed under the following climatic conditions:

Air temperature:

+5 to +30

С