5238-E P-105

SECTION 7 FIXED CYCLES

•

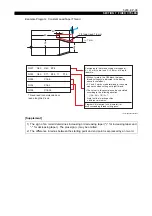

Extra Length in Thread Cutting Program

Since a certain length of incomplete thread is usually produced near the start and end point of

the cut, it is necessary to add appropriate amounts

δ

1 and

δ

2 at the start and end of the thread

to be cut in order to cut the proper thread shape.

LE33013R0300900060005

Values

δ

1

and

δ

2

vary depending on the cutting conditions. Generally, these values must satisfy

the following equations:

LE33013R0300900060006

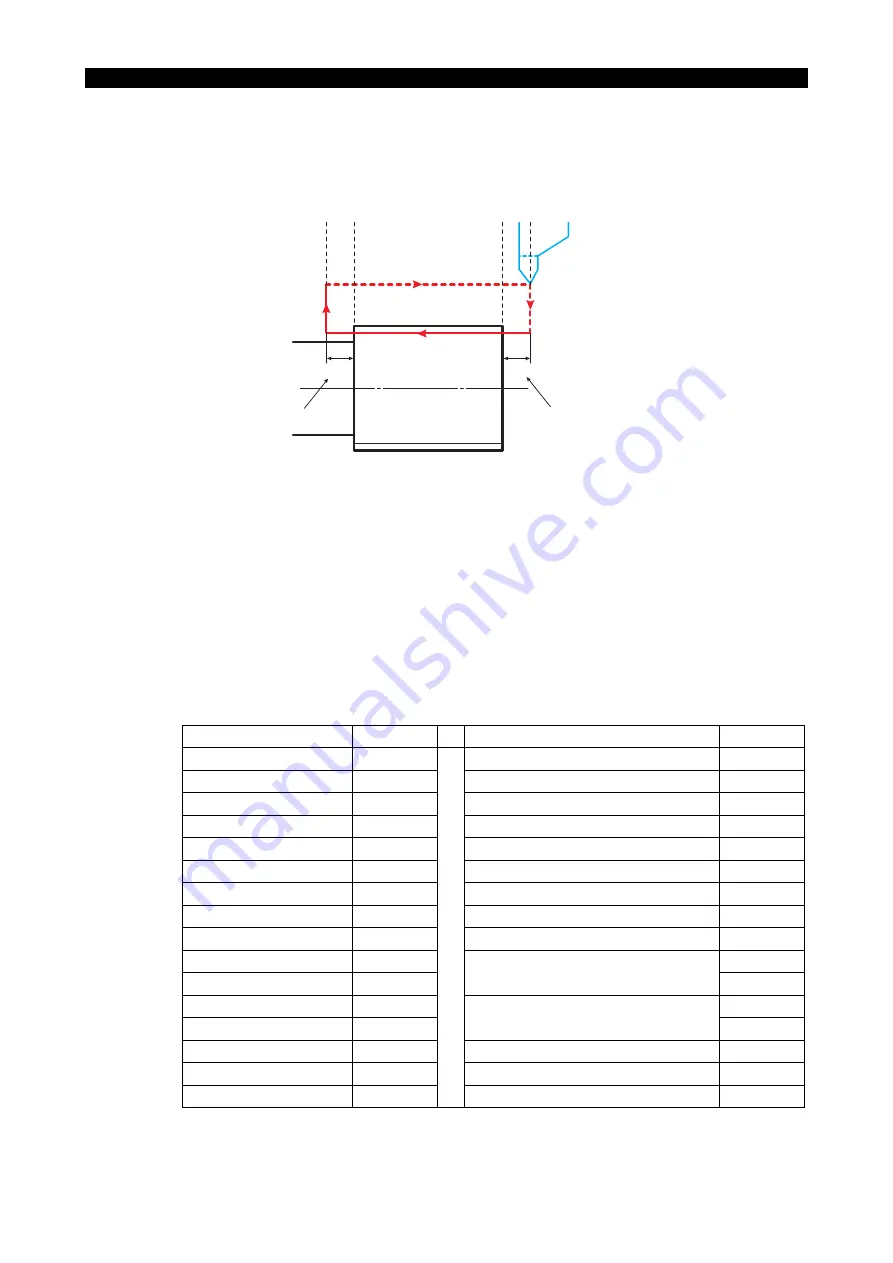

The values of constant K for individual models are indicated below:

Model

K[X10

-3

]

Model

K[X10

-3

]

LB200

0.48

MACTURN250

1.17

LB200MY

0.64

MACTURN350

1.39

LB250

0.48

MACTURN550

1.60

LB300

0.53

MULTUS-B300

1.07

LB300MY

0.64

LVT300

0.75

CAPTAIN L370

0.53

LVT400

1.07

LB400

0.64

LT200

0.75

CAPTAIN L470

0.64

LT300

1.28

LB35II

1.28

LCS250

0.96

LB45II

0.96

LAW-2S

1.28

LB45IIMY

1.17

(Priority given to smooth cut surface)

2.56

LU35

1.28

LAW-F

0.85

LU45

1.28

(Priority given to smooth cut surface)

2.56

LU300

0.53

LFS10

0.85

LU300MY

0.64

LF150G

0.64

LU400

0.64

LOC650 (LC50)

0.96

Z4 Z3

Z2

Z1

δ

2

δ

1

(Approach distance)

Length of incomplete thread

δ

2

> K

×

N

×

P

δ

1

> K

×

N

×

P

where,

N: spindle speed

P: lead

K: machine-model-dependent constant