5238-E P-261

SECTION 11 PROGRAMMING FOR SIMULTANEOUS 4-AXIS CUTS (2S Model)

•

Determine the cutting conditions so that a total of the cutting power required by the two turrets

will not exceed the capacity of the machine.

Other considerations

•

The use of the INDIVIDUAL switch allows the turrets to be operated independently, facilitating

checking of trial cuts.

•

Care should be taken to avoid interference:

•

Interference between the boring bar and the chuck

•

When performing end face cutting with the tools on turret A:

Interference between tools on turret A and boring bar on turret B,

Interference between tools on turret A and ID toolholder on turret B

•

Program movements of the tools on turret B taking into account those of turret A.

G02 and G03 should also be programmed taking cutting with the tools on turret A into account.

•

In constant speed cutting mode operation called for by G96, G110 and G111 select the turret on

which constant cutting speed is obtained: G96 G111 calls for constant speed cutting for turret B

and G96; G110 cancels G96 G111 and selects constant speed cutting mode on turret A.

This feature generates large differences in cutting speeds for the tools on turrets A and B when,

for example, performing simultaneous cutting on a workpiece with large diameter differences.

Therefore, the cutting portion handled by each turret and the cutting tip material should be

selected very carefully.

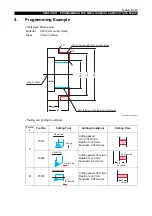

Program example:

LE33013R0301300060002

G13

G00

G96

X1

X2

Z1

Z2

P10

P20

S120

S100

M41 M03

T0101

G01 G110

G13

G00

G96

X3

X4

Z3

Z4

P10

P20

S120

S100

M41 M03

T0101

G01 G110

The G96

S, M and P commands of

turrets A and B must match.

Even when the constant

speed cutting mode is in

effect, it is active only on

turret A and turret B is

not this mode.