5699-E P-18

SECTION 3 OPERATION (OF CNC LATHE)

9-

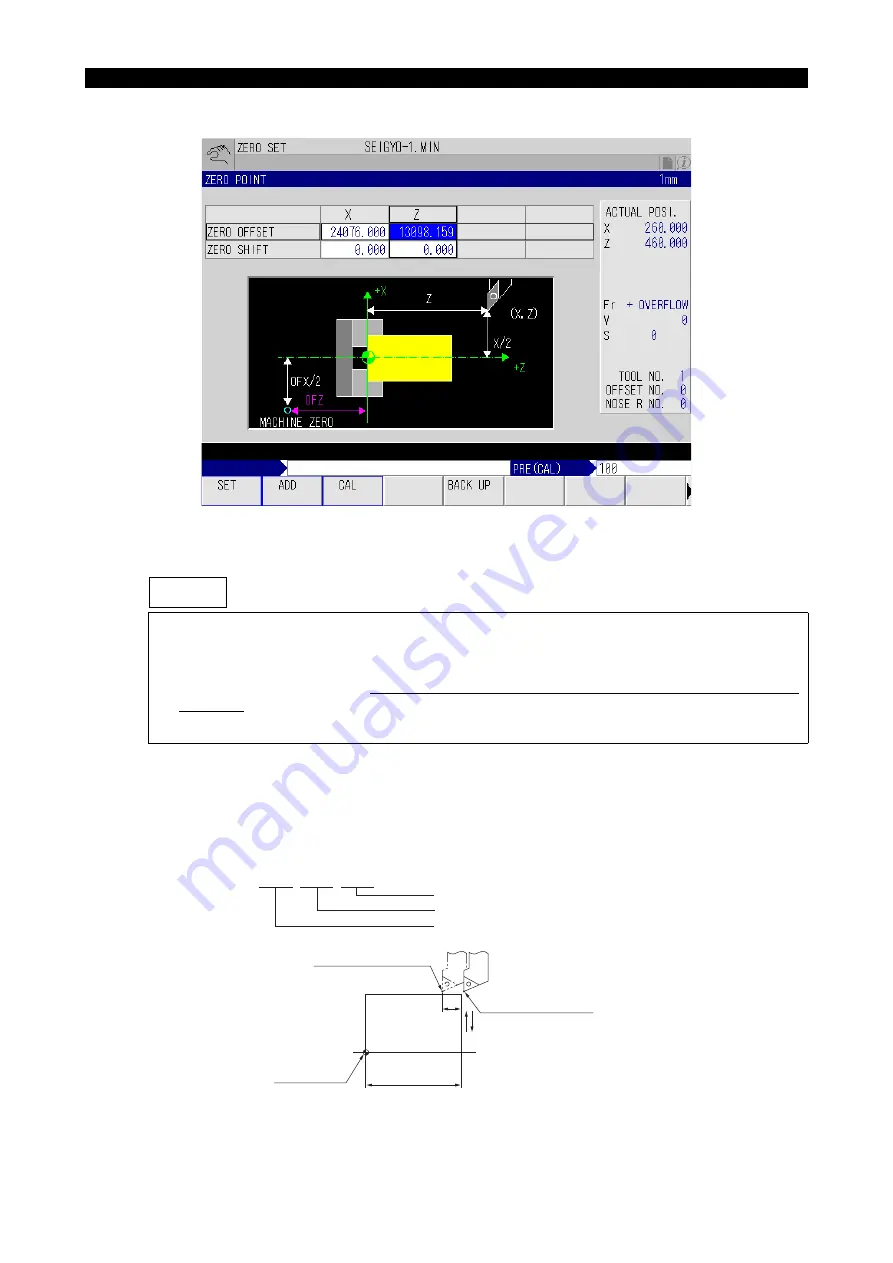

The screen displays the results of calculation or set value.

LE11214R0100500070010

This completes setting the zero offset value.

CAUTION

If the tool offset values are not zero, the zero offset setting procedure will differ from the procedure

indicated above.

The numeral data entered through the keyboard in the above step

“8-”

is the sum of “measured

value” and “tool offset value”.

LE11214R0100500070011

•

Never move the turret in the Z-axis direction until zero offset setting is completed.

Keep locating the turret in the position set in the step

“1-”

.

•

For the X-axis, the reference point does not change even when the checking method or

setup changes. Therefore, there is no need to carry out zero offset each time the set up

changes.

•

Use a tool with offset values of X = 0, Z = 0, where practicable, for zero offset setting.

Cutting tool with tool offset

Z=0

Cutting tool with tool offset

Z=-0.500

0.5

(0.02)

100 (3.94)

Reference point for

machining

(program zero)

Unit : mm (in.)

Example:

A tool with a tool offset value of Z = -0.500 is used.

The zero offset value is calculated as

100.000 + (-0.500) = 99.500

Setting value

Tool offset value

Measured value