Page 6

www.oldschoolmodels.com

Construction Manual

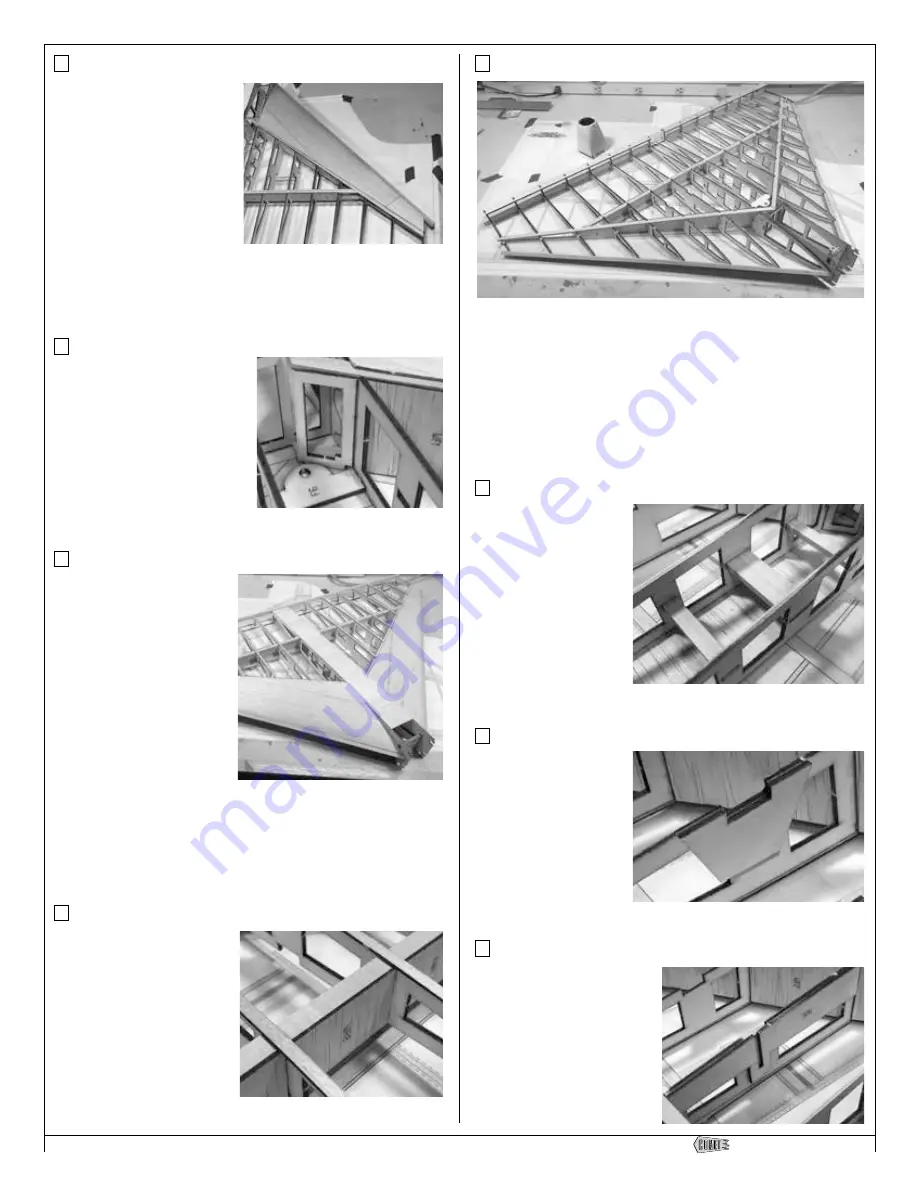

Step 26 - Wing Assembly (attach sheeting)

Take two of the completed

leading edge sheets from the

previous step as they will be

glued in position on the top of

the wing, as shown here.

We find it best to lay a bead

of glue along the edge of the

sheeting where it butts up

against the leading edge .

Make sure it is also contacting

each of the ribs. As a general rule, don’t use super-fast curing C/A’s

for the step as you will need a bit of time to make sure everything

is in place.

Glue one sheet on the left and the right wings.

Step 27 - Center Section (install F4)

Locate both F4s from the LP2

sheets. These are glued in place

as shown here, adding structural

strength by tying both the upper

and lower front spars to the

center section.

Don’t go overboard, but do use

a good amount of glue to make

sure these pieces are properly

secured to the spars and to the center section sidewalls (R1).

Step 28 - Center Section (top sheeting)

Using a bit of the leftover

1/16” sheeting from the BP6

and BP8 sheets, measure,

cut and glue together the

sheeting to cover the top of

the center section.

When measuring, make sure

that the grain is crosswise

(flowing from R1 to R1).

When edge gluing the

sheeting pieces together, first

make sure the edges are flat

(give a quick, swipe or two

with a sanding block).

Work from the rear of the center section, forward. You’ll need to

cut and join a few pieces together but be sure to stop an inch or

two behind the F5 (nose gear mount). You’ll need this open to aid

in mounting your powerplant.

Step 29 - Wing Assembly (cap strips)

Cut several 1/16th x 1/4” x

36” balsa strips from BP9.

Carefully measure and cut cap

strips to cover the top of each

R2-R8 rib. These strips should

be centered on each rib and

extend from the trailing edge

stock up to the back of the

leading edge sheeting.

Step 30 - Wing Assembly (tab removal)

Once all the glue has cured, remove the Comet assembly from the

building surface and flip it over.

Now it’s time to remove all the tabs from the ribs. All ribs will have

a rear and forward tab, as well as the smaller tabs that held the

lower spars in place. All of them need to be carefully cut away

and the ribs lightly sanded to maintain their airfoil shapes. There’s

a number of ways to do this but we find a Japanese saw is the

perfect tool. These saws are small, have flexible blades and the

lack of off-set teeth makes a smooth, straight cut.

Step 31 - Center Section (servo rails)

You should have several

leftover lengths of the

3/16” x 3/8” basswood

from trimming the spars.

These pieces will be used

to create the servo rails in

the center section. You’ll

need two of them - one

rear, one front, and two

which are back-to-back in

the middle slot.

Glue these in position.

Step 32 - Wing Assembly (R3C)

Locate both R3Cs from

LP2. These are doublers

for the main gear. They

are attached to the inside

edge of each R3. The

groove should line up

with the matching groove

in R3, and the edges of

R3C and R3 should be

flush with each other.

Step 33 - Wing Assembly (R2C)

Locate both R2Cs from LP1.

These are also doublers for the

main gear. They are attached

to the inside edge of each

R2. The long slot should be

aligned in the middle of the

slot in R2. Also, the edges of

R2C and R2 should be flush

with each other.