Page 14

www.oldschoolmodels.com

Construction Manual

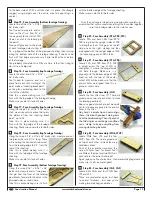

Glue one CG9 to each side of CG8, making sure they're nice and

perfectly aligned. Then do the same to create the other CG8/CG9

sandwich

- mmmmmm, yummy!

■

Step 85 - Fuse Assembly (F1, F2)

Locate F1 and F2 from LP5. These are

glued together, but a little care needs to

be taken here.

Note all the fancy etching on the front

of F1. This needs to show once the

parts are glued together. So F2 will be

attached to the back of F1. Also, the hole in the center of these

pieces match up, but are not symmetrical. Test "fi t" them together

to make sure how they align. The cutout circles will match, the left

and right sides will align, as will the top edge.

The bottom edge however, will not.

So, when you're ready mix up some epoxy and make these two

pieces become one. Clamp things up to make sure they stay in the

right place while the glue cures.

IF, AND ONLY IF

- you are going to use electric power for

your GHOST, you'll need to make this assembly -

the electric fi rewall.

If going glow, sounds good - skip to step 88.

■

Step 86 - Fuse Assembly (electric fi rewall - E1, E2)

Locate EF1 from LP7 and EF2 from

LP5. These are glued together, but

a little care needs to be taken here.

Note more of that fancy etching on

the front of EF1. This needs to show

once the parts are glued together.

So EF2 will be attached to the back

of EF1. Also, the hole in the center

of these pieces match up, but are

not symmetrical. Test "fi t" them together to make sure how they

align. The cutout circles should align when all the sides line up.

So, when you're ready mix up some epoxy and make these two

pieces become one. Clamp things up to make sure they stay in the

right place while the glue cures.

■

Step 87 - Fuse Assembly (glow fi rewall)

Also, if you're using electric you'll need to

cutout a few holes in the glow fi rewall (F1/F2).

We've etched the areas that should be cutout.

The holes are simple 1/4" holes that can be

handled by drilling them out. The elongated

hole on the bottom can be drilled out with the

same 1/4" on each end, then the area between

the holes can be fi led/cut away. Most of these holes allow for air to

fl ow over the battery and ESC. The elongated hole on the bottom

allows the motor's three wires to enter the fuselage.

■

Step 88 - Fuse Assembly (F4A, F4B, F4C)

Locate F4A, F4B and both F4Cs from

LP5. F4B is glued across the center of

F4A, making the sets of holes are aligned

between the two parts.

The F4Cs go across the top and bottom

of F4A. Note their positions in the photo.

The top F4C is just below the upper tabs. The lower is aligned with

top of the lowest cutout.

■

Step 89 - Fuse Assembly (F3, TR1)

Locate TR1 from LP4 and the F3

assembly. TR1 is pushed through the

center of F3 at an angle, then rotated

so the left and right uprights of F3 fi t

into TR1's slots.

TR1 should rest on the two small

triangle supports when it's glued

in place, with it's etched circle in the corner, positioned on the

starboard side. Also note the orientation of F3B, it will face the

larger portion of TR1.

Make sure these two pieces are exactly 90° to each other when

gluing them together. (Remember that triangle from earlier?)

■ ■

Step 90 - Fuse Assembly (servo rails)

Now here's another cool thing that's designed into each and

every GHOST. Those smart folks in the OSMW Department of

Awesomeness have integrated our exclusive Multi-Size Servo

mounts into the GHOST - they're everywhere, including the sides

of the fuselage.

So, let's do this thing. You're gonna need a few things for this. The

fi rst is to grab one of the fuselage sides - doesn't matter which one.

Next you'll need your elevator or rudder servo - again doesn't

matter which one. You'll need to pop out six of the small "

h

"

shaped servo rails and two of the small servo rectangles. They're all

over the LP sheets -

BUT DON'T USE THE ONES ON BP8 - Those

are "L" shaped and used for the wing's servos.

Lastly, you'll need one of the SHGs from LP1 or LP2. Yup, that's a

lot of stuff, but it'll all make sense in just a little bit.

Put three of the “

h

” shaped rails into the

SHG as shown here. This little guide/jig/

thing-a-ma-jig makes it easy to align these

three small pieces - just make sure you

don't glue the rails to the SHG.

Make two rails.

■ ■

Step 91 - Fuse Assembly (servo rails)

Those two servo rails can now be

pushed into the pre-cut slots in the

fuselage ply framing. Push in the rail

that'll be more "forward" fi rst, then

use your servo to gauge where the

other rail should be placed. Mark this

on the fuselage, remove the rails,

apply glue to them and then fi x them

in place permanently.

Also glue a small rectangle on top of each rail, as we've shown

here.

■ ■

Step 92 - Fuse Assembly (mount the servo)

Now you can drill and attach the servo

to the inside of the fuselage, using the

servo's mounting screws.

This might seem like a strange time to

do this, but it works quite well, as you

have more room to make this happen

than you will later on.

WH6

F3B

WH4

WH7

WH7

WH7

WH7

CG9

CG9

WH2

F1

F4A

F4C

F4B

F2

EF2

W1P

W1P

W2

S2

F3A

H8

CG8

CG8

CG9

CG9

TR1

T2

T4

H2

H1

T2

T3

T3