Construction Manual

www.oldschoolmodels.com

Page 23

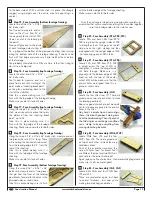

Installing the fl aps:

Locate the other two SH1s from LP7, as well as twelve of the "

L

"

shaped pieces and 4 of the small rectangles from LP8.

Using the same techniques you used when creating aileron servo

rails, you'll make 4 servo rails, then glue the rectangle on top.

This time however you

won't make two mirror

images - these both need

to match, as shown here in

the pic

.

Center the servo arm as

before, then glue the rails on

each side of the servo.

These fi nished hatches can then be covered, and mounted into the wing.

Note: you may have to remove the covering in the fl ap servo bays, if you

haven't already. And the servo wires are run through the ribs and exit out

the same center holes the aileron wires are exiting. These servos should be

connected to a "Y" harness, then into a spare channel of your receiver -

hopefully one that works via a 3-position switch on your transmitter.

In the wing, there was a single 1/4" x 1/4" piece that was installed between

ribs R2 and R5, on

the underside of the

wing.

This is the piece that

the fl ap's hinges will

be mounted to.

Using the same

hinging technique as before, mark the three places where you'll need to cut

slots to match the hinges already glued to the fl aps. Then insert one of the

fl aps and make sure the hinges are all the way into the wing. Use drops of

thin C/A glue to attach the fl ap.

Then do the same to mount the remaining fl ap under the other side of the

wing.

Now you'll connect the control horns and the

back to the FP4 plate, using two of the 2-56 x

5/16" screws for each fl ap.

Short pushrods are then hooked up between

the servos and control horns. When the servo

is at one extreme, both fl aps should be fl at

against the bottom of the wing. When the

servo is extended, the fl ap should be at

roughly a 45° angle, as shown here.

Flaps are meant to be used at slower speeds

to increase the lift dramatically - and allowing

for higher rates of climb and much slower fl ight.

DON'T DEPLOY THESE AT

SPEEDS OVER 1/2 THROTTLE, as you could damage them.

Also, when deploying them, the GHOST will tend to climb, and sometimes

climb signifi cantly, so you'd need to hold more down-elevator to keep it

fl ying level. This is not unique to the GHOST - it's the way fl aps effect most

designs - but if your radio allows, you can add some mixing to automatically

add down elevator when the fl aps are deployed.

We found it best to use fl aps on channel with a 3 position switch. When

retracted completely, no need for

elevator trim. When the fl aps were half-

way extended, we mixed in 10% down

elevator. With full fl aps, we mixed in

25% down elevator. You're mileage may

vary, but these are good starting points.

cases, the radio should be charged the night before going out fl ying.

Check the radio installation and make sure all the control surfaces

are moving correctly (i.e. the correct direction and with the

recommended throws). Test run the engine and make sure it

transitions smoothly from idle to full throttle and back. Also ensure

the engine is tuned according to the manufacturer’s instructions, and

it will run consistently and constantly at full throttle when adjusted.

Check all the control horns, servo horns and clevises to make sure

they are secure and in good condition. Replace any items that would

be considered questionable. Failure of any of these components in

fl ight would mean the loss of your aircraft.

Range check your radio before fl ying

Before each fl ying session, range check your radio. This is

accomplished by turning on your transmitter with the antenna

collapsed. Turn on the radio in your airplane, but do not attach the

arming switch.

With your airplane on the ground, you should be able to walk 30

paces away from your airplane and still have complete control of all

functions.

If not, don’t attempt to fl y! Have your radio equipment checked out

by the manufacturer.

Shot of our DX18 transmitter's

fl ap setup for the GHOST.

Installing the Fun Fly Bay Accessory kits

(available separately)

:

As you probably know by now, we are developing several accessory

kits that can be mounted inside the GHOST's fuselage. Each of

these will mount the same way.

With the wing removed, you can look down on the two CG8/9 rails

that were installed during the fuselage build. There are two holes

pre-cut into them. Run a 3/32" bit through these holes to make

sure they're free of glue.

Now with that fi nished, each of the accessory kits will push in

from the bottom and mount using the two supplied 4-40 x 1"

socket head cap screws from the

hardware bag, as shown here.

Simply bolt in the module with

the screws (through the wing

saddle after the wing is removed),

then plug the servo into a spare

channel that you'll use to control

the module. Do the reverse to

swap out to another module.