Construction Manual

www.oldschoolmodels.com

Page 7

■

Alignment triangle

Before we start on the wing construction,

there's a couple of tools that are pre-cut

into this kit.

One is a 90° triangle in LP1. It can be

used to vertically align any of the parts in

the construction of your GHOST. LP1 also

includes a foot piece that can be used with

the triangle to hold it vertically (hands-free).

■

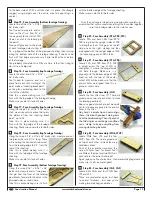

Step 24 - Wing Assembly (prepare your work area)

Position the port wing plan over your

fl at building surface and tape it in

position. Tear off a length of waxed

paper long enough to cover that

portion of the plan and tape that over

the plan.

■ ■

Step 25 - Wing Assembly (bottom spar)

Locate one of the 3/16" x 3/8" x 36"

basswood sticks. This is used as the

lower wing spar. Position it on the plans

so it extends roughly a 1/4" past the tip,

as shown here. Now move to the other

end and mark the stick about 1/4" past

the innermost (root) rib - R1.

Cut this stick to length.

Then it needs to be attached in place over the plans. We use a few

drops of medium C/A to tack-glue this piece to the waxed paper

to hold it in place, instead of t-pins. Use your long straight-edge

to make sure it is aligned properly and is straight over it’s entire

length. The alignment of this spar is critical as the rest of the wing

panel is based off this single piece.

■ ■

Step 26 - Wing Assembly (LE1, LE2)

Locate one LE1 and one LE2

from BP11. These two pieces

will become the lower portion

of the leading edge.

Pin LE1 in place fi rst, then

apply glue where LE2 and LE1

contact each other - around that

modifi ed "scarf" joint.

Pin LE2 in place, using your

straightedge to guarantee the straightest of straightnessship.

■ ■

Step 27 - Wing Assembly (TE1, TE2)

Locate one TE1 from BP11 and TE2

from BP15. These two pieces will

become the lower portion of the

trailing edge.

Pin TE1 in place fi rst, then apply glue

where TE2 and TE1 contact each

other - around that modifi ed "scarf"

joint.

Pin TE2 in place, using your

straightedge to again guarantee the most straightest of straightness

that has ever been straight.

■ ■

Step 28 - Wing Assembly (T1, T2, T3, T4)

Locate T1 from BP10 as well as T2, T3

and T4 from LP4.

Place T1 fl at on your building surface,

in the same orientation as shown on the

plans, then you'll glue T2, T3 and T4 into

T1. Make sure each piece is perfectly

vertical - remember that 90° triangle?

■ ■

Step 29 - Wing Assembly (R7)

Locate one R7 from BP6. It is

glued to the tip assembly you just

made. Test fi t it fi rst, making sure

you know how all the tabs in each

of the T1-4 pieces fi t.

When you're ready, remove R7,

apply glue in the correct spots

and attach R7 in place.

■ ■

Step 30 - Wing Assembly (tip assembly)

The tip assembly is now glued in

place to the spar, as well as the

leading and trailing edges. You'll

note that there are notches in the

leading and trailing edges which

help position this rib, as well as the

rest of them (as you'll fi nd out).

This tip assembly will also rest on

the spar, holding it 90° without the use of tools - yup, another great

innovation from the OSMW Design Squadron Think-Tank.

Anyway, once you see how it's attached, apply glue to the spots

where the tip assembly contacts the other parts, then glue it in

place.

■ ■

Step 31 - Wing Assembly (webs)

Enter the webs, W3 shear-webs that is.

You'll have a bunch of these on BP11,

BP14 and BP15. You'll use one of these

along with a rib over the next few steps.

These webs add massive strength to a

wing, with very little weight.

These webs do fi ve things at the same time.

1. They give you proper rib spacing with tabs that lock into the

rib's pre-cut slots (our exclusive WEB-LOCK construction).

2. They hold each rib perfectly vertical without needing tools.

3. The cutout GHOST face lets you easily know which way is

up - an upright face is the correct way.

4. The eye cutouts allow airfl ow between the different

chambers of the wing. This is very helpful in keeping

covering from bubbling up when you're covering later on,

and when the GHOST is at the fi eld in the boiling sun.

5.

They just look really cool.

Yup, another bright idea from the warped minds of those who work

at the OSMW Development Center.

■ ■

Step 32 - Wing Assembly (W3, R5)

Locate one R5 from BP4, BP5 or BP6. Also locate one W3 web and

test fi t it against R7. It should be placed so the face is upright, it's

tab is pushed fully into the slot in R7, and this web is fl ush against