Page 4

www.oldschoolmodels.com

Construction Manual

n n

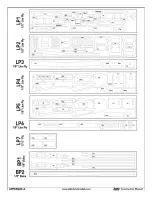

Step 3 - Wing Assembly (front spar)

Locate another SP2 from BP1

and this is now glued on top of

the SP1 you just installed. This

will allow the lower and upper

scarf joints to overlap, rather

than be aligned. Again, make

sure that this SP2 is glued to

the SP1 (and the overlapping portion of SP2) below it, as well as

where it contacts the basswood strip. Make sure this joint is straight

as shown here.

n n

Step 4 - Wing Assembly (front spar)

Now locate another SP1 and glue

in place, aligning the laser-cut scarf

joints and making sure it is properly

positioned as the glue cures.

n n

Step 5 - Wing Assembly (front spar)

To complete this spar, locate another

of the 1/4” square basswood strips.

Glue this to the edge of the spar

assembly, to the edges of the SP1

and SP2 pieces as shown here. Make

sure it’s flat and straight along it’s

entire length.

n n

Step 6 - Wing Assembly (front spar)

Once the glue has cured in the spar assembly, remove it from the

building board and lightly sand it’s surfaces to make sure they are

flat and smooth, removing any glue bumps that may have formed

during the assembly and curing. Don’t go overboard - just make

sure that you have a piece that is flat on all sides so it will slide

smoothly into the ribs during the upcoming steps.

n n

Step 7 - Wing Assembly (rear spar)

Now locate two of the 1/8”

square basswood strips, one

SP3 and one SP4 from BP1.

Using these pieces you’ll

make the rear spar, using the

same techniques as you did

for the front spar. Start by

gluing the long edge of SP3

to the basswood strip, making sure it’s straight along it’s length.

Then glue SP4 in place, lining up the scarf joint. Follow it all up with

the other length of basswood glued to the exposed edges of SP3

and SP4. Lightly sand it flat in preparation for the upcoming steps.

n n

Step 8 - Wing Assembly (R2/R2A, R4/R4A)

Now locate one R2 from BP1, one

R4 from BP3, one R2A from LP3

or LP5 and one R4A from LP3 or

LP4. Pay careful attention to the

orientation when doing this as

you'll be gluing R2A to the outside

face of R2 (towards the wing tip)

and R4A to the inside face of R4

(towards the wing root). When glued in place, R2A and R4A need to

be perfectly aligned with top and bottom edges of their respective

ribs. Also the rear edge should be just on the edges of R2A and

R4A should be aligned with the rear spar cutouts in each rib.

n n

Step 9 - Wing Assembly (wing ribs)

Now locate one complete

set of wing ribs. Stack them

up in order by referring to

the plans. Starting at the

root: R1, R2, R2/R2A, R3,

R4/R4A, R5, R6, R6, R5, R5,

R5, R5 and R7. Make sure

you align them correctly with

the under-side tabs all in the

same direction. Double, triple, and quadruple check that you have

them in the correct order, then when satisfied, push the front spar

into the larger rectangular hole in each rib. The rear spar is pushed

through the smaller rectangular hole towards the rear of the ribs.

n n

Step 10 - Wing Assembly (wing ribs)

Now place this “assembly”

onto the wing plan on your

building board and start

to carefully space the ribs

apart so they align with the

plans. Take your time and

use a light touch so you

don’t break off any of the

underside tabs, or crack any

of the ribs. They don’t need to be perfectly aligned yet, but get

them close. Double check that all the ribs are in the right order one

more time as in the next step everything is locked in place, making

this the last time you’ll be able to easily fix any mix-ups.

It’s worth

one more look now - trust me.

n n

Step 11 - Wing Assembly (wing ribs)

Starting at the tip rib (R7), it’s

time to start gluing things in

place. I like to put a small drop

of medium CA on the bottom of

the underside tabs of this rib to

help lock it in place to the waxed

paper (or you can use pins if

that’s your thing). Also make sure

to use the enclosed triangle that you should have at hand from the

first steps of this build. This ensures that this rib is perfectly aligned

at 90° to the building surface.

Also make sure that the front and rear spar protrude a little from

R7 - maybe an 1/8” or so.

When satisfied, glue the two spars to R7.

n n

Step 12 - Wing Assembly (wing ribs)

Now, slowly and methodically work your way towards the root rib,

one rib at a time. Make sure each rib is precisely aligned - the

spars are aligned, and that you firmly glue each rib to both spars.

As you go along, you also might want to place a drop of glue on

the underside tabs on every third or fourth rib to keep everything

aligned with the plans. Continue with this until you have glued the

R2/R2A rib in place. Stop there and move on to the next step.