Construction Manual

www.oldschoolmodels.com

Page 7

n n

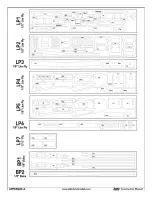

Step 31 - Wing Assembly (LE & TE)

Locate one LE and one TE from BP14. These are the lower leading

edge and trailing edge sheeting and should be applied in the

same way as you applied the top side sheets.

n n

Step 32- Wing Assembly (root, tip sanding)

Take a few minutes to carefully sand away any extra wood that

extends past the root (R1) and tip (R7) ribs. Cut and/or sand as

necessary until any extra spar or sheeting material is perfectly flush

with those ribs.

n n

Step 33 - Wing Assembly (TP1)

Locate one TP1 from LP1. This

is glued in place to R7 as shown

here. It should be at 90° to R7

(perpendicular) and all the TP1

tabs should fit completely into

the pre-cut slots in R7.

n n

Step 34 -Wing Assembly (T2, T3, T4)

Locate two T2s and T4s from

BP11S as well as two T3s from

BP12S.

Make sure you're using BP11S

& BP12S for the starboard

wingtip - NOT BP11P & BP12P.

Glue the two T2s together to

make a thicker T2 - perfectly

aligned of course. Then do the

same for the T3s and T4s.

Note the etched lines on T2 and

T3. These are alignment guides

for the piece that fits on top of

them. With the wing sitting up-

right, glue T2 on top of TP1 and

up against R7. Then glue T3 on

top of T2, aligning T3 with the

edges guides and up-against R7. Then finally T4 on top of T3,

aligned and up-against R7.

n n

Step 35 - Wing Assembly (T5, T6)

Locate both T5s and T6s from

BP11S. Glue both T5s together,

then both T6s together. Then

these are glued to the underside

of TP1, T5 first, then T6 using T5's

etched lines as a guide.

n n

Step 36 - Wing Assembly (aileron box)

First we’ll create the mounting

rails for the aileron hatch by

using leftover 1/4” square

basswood you trimmed when

creating the forward spars.

Measure and cut two lengths

that will span the distance

between the forward and arf

spars. With the wing half laid on it’s top, glue these two strips to

the R6 ribs as shown on the plans. These strips should be flush with

the lower-most pre-cut edges of the R6 ribs.

n n

Step 37 - Wing Assembly (aileron box - SH1)

Next locate two SH1s from BP15. These are glued to R6’s small

ledges just behind the front spar and ahead of the rear spar. Glue

these, centered across the two R6 ribs as shown on the plans.

n n

Step 38 - Wing Assembly (aileron box - SH)

Locate one SH from LP5. This should now fit in the area between the

SH1’s you just installed. If not, lightly sand as necessary to obtain a

good fit. Note that there are 4 holes precut into the corners. With

a 1/16" bit, use SH as a guide to drill the 4 holes that will be used

to attach SH to the wing using 4 of the supplied 2-56 self-tapping

screws. Temporarily attach the hatch in place using these screws.

n n

Step 39 - Wing Assembly (aileron box)

Now locate some of the scrap 1/4” square balsa stock trimmed

away from the trailing edge pieces. Cut two lengths that will run

between the front and rear spars. Glue these in position as shown

on the plans - flush with the top surface of SH1, and against the

1/4” square basswood mounts. Do NOT glue them to the SH hatch

as that needs to be removable.

Set the starboard wing half aside and begin work on the port

wing half. Tape the port wing plan and fresh wax paper on

your board. Then follow steps 1 through 39 to complete the

starboard wing half. Once finished, then move on to step 40.

Note that when building the port half that many of the parts will

need to be glued to the opposite side (the WH1, WH2, and the

wing tip pieces for instance). Always refer to the plans to make

sure you’re gluing the parts together in the correct way.

n

Step 40 - Wing Assembly (D1, D2)

Locate D1 from LP3 and D2 from LP2. These are the dihedral

braces. Test fit these by sliding them into both of the wing halves,

as shown. They should smoothly push into the gap in the R1, R2

and R3 ribs until each brace is half way inserted. Also make sure

that you insert them both in the same orientation - so they both

point “up” when the wing is held upright.

Carefully sand as necessary so they both slide in as they should,

and allow the root (R1) ribs on both halves to fit flat against each

other, along their entire length.

Once satisfied with the fit, take the wing halves apart and remove

D1 and D2.

Now it’s time to mix up some epoxy and use it to coat the areas

where the D1 and D2 pieces will contact the spars and ribs. Also

coat the entire face of one of the R1 ribs.

When coated, slide all these

pieces back together to form

the completed wing assembly.

Hold these together with some

tape and/or clamps until the

epoxy has cured completely.

While waiting for the glue to

cure, wipe away any excess

with a paper-towel soaked in a bit of denatured alcohol.