28

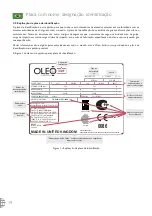

OLEO INTERNATIONAL

LB 50-65

11

10

9

8

7

6

5

4

3

2

1

Posizio

n

are

l’i

n

terr

u

ttore e le

viti

Tappo

d

i plastica

ri

m

osso e

s

m

altito

Gr

u

ppo staffa

d

i

posizio

n

a

m

e

n

to

i

n

posizio

n

e

Alli

n

eare la staffa

co

m

e

m

ostrato

Fissare il

d

a

d

o

sal

d

a

m

e

n

te alla g

u

i

d

a,

applicare il fre

n

afiletti

(es. Loctite 242/243)

stri

n

gere il

d

a

d

o co

n

coppia

d

i serraggio

d

i

10 N

m

(8 ft/lbs)

Tappo e ro

nd

ella

pri

m

a

d

el

m

o

n

taggio

Ro

nd

ella ri

m

ossa

e s

m

altita

Spi

n

gere la leva

i

n

ava

n

ti fi

n

o a

toccare l’asta

d

i

spi

n

ta

Gr

u

ppo staffa i

n

posizio

n

e al

d

i

sopra

d

el co

d

olo

filettato

Leva che

tocca

legger

m

e

n

te

l’asta

d

i

spi

n

ta

Leva che tocca

legger

m

e

n

te lo

sta

n

t

u

ffo

d

ell’i

n

terr

u

ttore

Co

n

il fi

n

ecorsa posizio

n

ato e

fissato i

n

posizio

n

e co

m

e

i

nd

icato i

n

fig. 9, ri

mu

overe la

copert

u

ra

d

el

n

astro a

d

esivo,

pre

m

ere co

n

d

ecisio

n

e il

sottopiastra co

n

tro la staffa,

lascia

nd

o f

u

ori

u

scire le

du

e viti

I

n

serire le

du

e ro

nd

elle e

d

a

d

i

per fissare l’i

n

terr

u

ttore

Ro

nd

ella e

d

a

d

o

Gruppo

interruttore

montato

correttamente

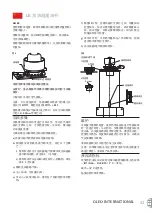

ISTRUZIONI DI MONTAGGIO DEL GRUPPO INTERRUTTORE

Nota: l’ammortizzatore deve essere in posizione completamente estesa prima di montare l’interruttore.

L interruttore viene fornito all interno di una busta di plastica, che viene fissata con del nastro adesivo sul lato del serbatoio

di espansione. Dal momento che gli interruttori sono fragili questi dovrebbero essere installati il più tardi possibile durante il

processo di montaggio, e sicuramente dopo che tutte le altre attrezzature pesanti siano state installate nel pozzo dell ascensore.

Seguire le fasi seguenti per l installazione:

Summary of Contents for LB 50

Page 32: ...31 Oleo 15 C 70 C Oleo 5mm Oleo Oleo LB 50 55 60 65 1 1 2 20 Oleo LB 50 55 60 3 1 20 2 3 LB...

Page 34: ...33 11 10 9 8 7 6 5 4 3 2 1 LB 242 243 10Nm 8ft lbs 9...

Page 37: ...36 OLEO INTERNATIONAL LB 50 65 15 C 70 C 5mm LB50 55 60 65 2 2 20 LB50 55 60 3 1 20 2 3...

Page 39: ...38 OLEO INTERNATIONAL LB 50 65 11 10 9 8 7 6 5 4 3 2 1 Loctite 242 243 10Nm 8ft lbs...

Page 44: ...43 LB 50 65 11 10 9 8 7 6 5 4 3 2 1 eg Loctite 242 243 10 Nm 8 ft lbs 9 2...

Page 49: ...48 OLEO INTERNATIONAL LB 50 65 11 10 9 8 7 6 5 4 3 2 1 242 243 10 8 9 2...