2

EN

1. GENERAL WARNINGS

- Read this manual carefully before installing this pump.

It contains every necessary information for installation,

correct use and maintenance of CMV pumps.

- It's very important that the user reads this manual

before using the pump. Any damage caused by failure

to observe the directions contained in this manual will

not be covered by warranty.

- By the time you receive this pump check

if it wasn´t damaged during transpor-

tation.

- In this case, please contact our agent as soon as

possible.

2. OPERATING CONDITIONS:

- The CMV are centrifugal multistage pumps and have

been designed to work with clean water at a maximum

temperature of 35º C.

- Maximum starts/hour: 30 at regular intervals.

3. INSTALLATION:

- The pump should be fixed to a solid base by bolts

through the holes in the bottom of the pump in order

to prevent unwanted noise or vibration.

- You should place pump as near as

possible to water level so to have the

minimum suction lift and reduce loss of

head.

- Make sure that pump is never submerged and that it

rests in a dry and well aired room.

4. PIPES ASSEMBLY:

- Suction pipe (Pic. 1) must be the same or lower

diameter than the pump inlet and must always remain

in na upward inclination of 2% so to help with correct

priming.

- A foot valve with filter should be installed and

submerged to at least 30cm below the well dynamic

level to prevent air from entering the pump.

- Be sure that discharge pipe (Pic. 1) should never rest

on top of the pump.

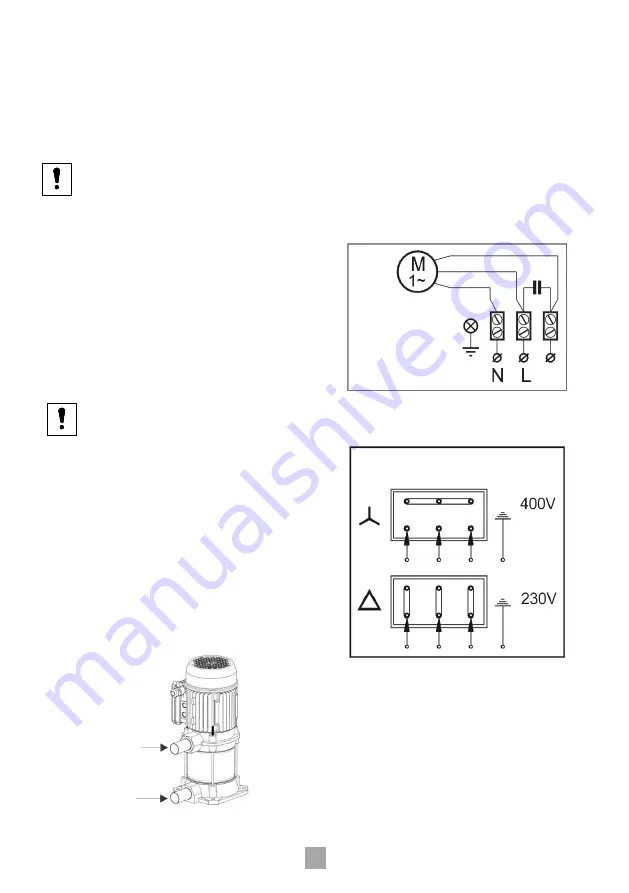

5. ELECTRICAL CONNECTION:

- The single-phase motors have a built-in thermal

protection.

- The electrical installation must have a system of

multiple separations with contact opening of at least 3

mm.

- The protection of the system will be based on a

differential swith ( I fn = 30 ma).

- The electric cable must correspond to the EEC (2)

norm or to the type H07 RN-F.

- With three-phase motors, end-user must install

himself the correct protection to the pump as per the

aproppiate installation regulations.

- Follow directions on Pic.3. for a correct electrical

connection.

6. CONTROLS PRIOR TO THE INITIAL

STARTING:

- Check that voltage and frequency correspond to

those indicated on the technical characteristics label.

- Make sure the motor shaft is turning freely.

- Fill pump body completely with water, as well as the

suction pipe, through the priming hole (Pic. 4). Check

that there is no leaking through joints or connections.

Pic.1

DELIVERY

SUCTION PIPE

Pic.2

SINGLE PHASE

SUPPLY

Pic.3

THREE PHASE SUPPLY