As electrobombas referidas nesta declaração,

estão em conformidade com a Directiva

73/23/CEE

(Directiva de Baixa Tensão). A plena

concordância com os requesitos essenciais da

Directiva é comprovada pela conformidade com

a norma

EN 60335-2-41

.

(Gerencia)

ENGLISH

-

Before carrying out checks

or doing any maintenance, clear

the system by disconnecting the

voltage, unplug the pump from

the socket and then rinse the

pump well with clean water.

- They are not suitable for

pumping inflammable liquids or

for operating in places where is

danger of explosion. Avoid contact

between the power supply and the

liquid to be pumped. Do not modify

the components of the water pump.

- The water pumps comply with the EEC

Directives 73/23/EEC, 98/037/EEC,

89/336/EEC including the latest amendments.

- Before installing the water pump, make

sure that the power supply mains is earthed

and complies with regulations.

1 - GENERAL WARNINGS

- These pumps are recommended for pumping

very dirty and sewage water. They must be used

in compliance with local laws.

- Before installation and use read the

following instructions carefully. The

manufacturer declines all responsibility in the

event of accident or damage due to negligence

or failure to observe the instructions described

in this booklet or in conditions that differ from

those indicated on the rating plate. It also

declines all responsibility for damage caused by

improper use of the water pump.

- When storing, do not pile weights or other

boxes on top.

2 - SAFETY

- The water pump must never be

lifted or transported by its supply

cable or float switch; it must be

held by the appropriate handgrip.

- Keep hands or other object away from the

hole under the pump casing near the

supporting feet.

- Do not use the pump in swimming pools,

garden ponds or similar places when people

are in the water.

4 - CONDITIONS OF USE

- The following conditions must be observed when

using the water pump::

a

Maximum fluid temperature: 40ºC.

a

Maximum density of the liquid pumped: 1,1

3

Kg/dm .

a

pH of the liquid: 5 / 9

a

Vo l t a g e v a r i a t i o n a l l o w e d : ± 5 %

(in the case of single-phase voltage

220/240V and three-phase voltage 380/415V

, these are the permitted limit values).

a

Protection index: IP 68

a

Max. immersion depth: 3 to 5 m.

- Unpack and check that it is in

perfect condition. Also check that the

data on the rating place correspond to

the required data.

3 - PERLIMINARY INSPECTION

- If there is any problem contact the supplier

immediately, specifying the type of fault.

- CAUTION: If there is any doubt about

the safety of the machine, do not use it.

ENGLISH

- Do not underestimate the risk of drowning

if the installation has to be performed in a well

at a certain depth.

- Make sure there are no toxic discharges or

harmful gases present in the atmosphere. If the

installation involves welding, take all necessary

precautions to avoid explosions.

- Always remember the danger of infection

and take all hygiene-health precautions.

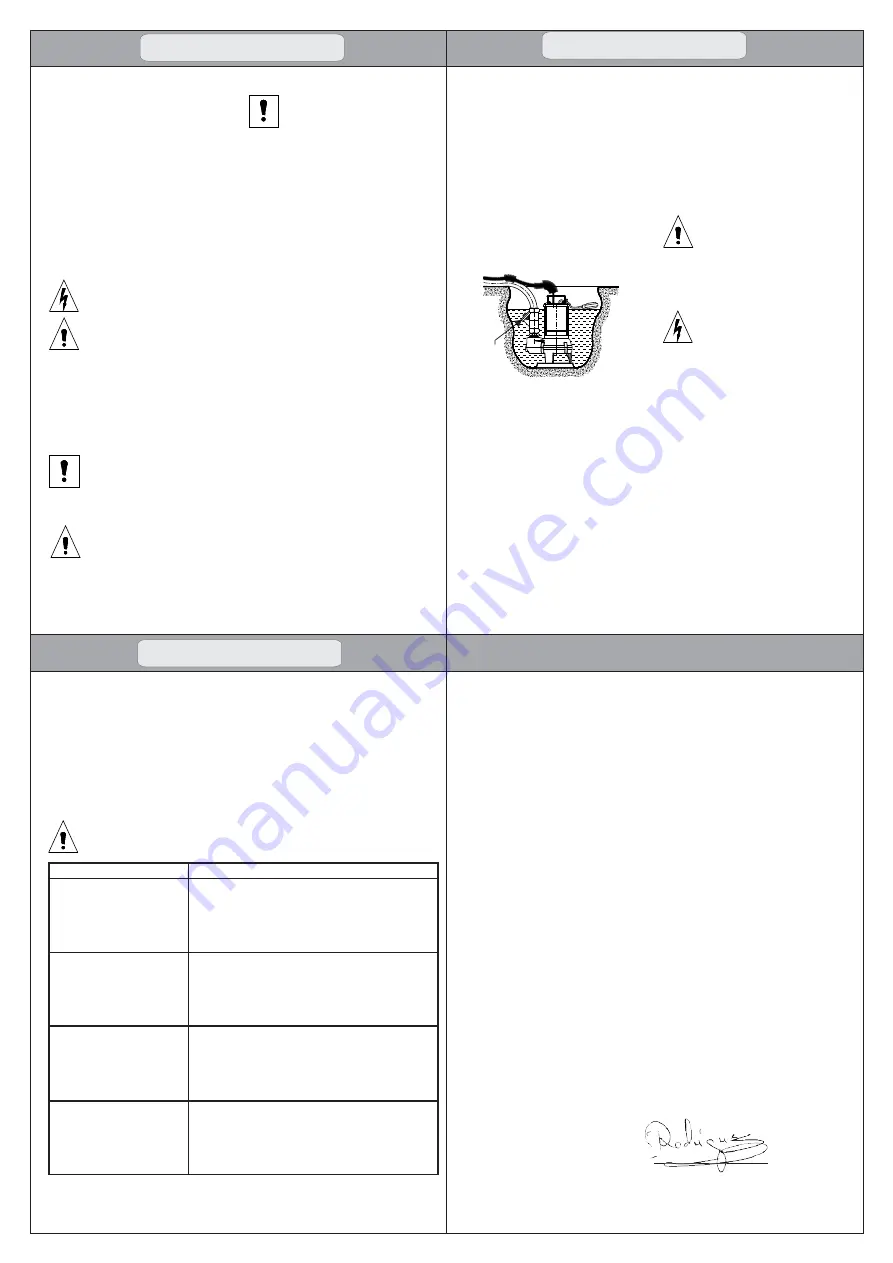

- If the bottom of the well or the surface on

which the pump rests is uneven and there is the

possibility of stones, debris, mud, etc.,

accumulating there, lay a level raised supporting

base (Fig. 1).

- The delivery piping may be either rigid or

flexible as long as the cross-section for passage

of the fluid is no smaller than that of the pump

delivery outlet.

- CAUTION: it is the installer's

responsibility to perform the connections in

compliance with the regulations in force in

the country of installation. Make sure that

there is no voltage at the line wire terminals

before connecting.

- Check that the data on the rating plate

corresponds to the rated line values.

CHECK

V

AL

VE

Fig. 1

ENGLISH

- You are advised to check the following

periodically:

a

The condition of the cables and

grommets, especially at their

attachment points.

a

T h e i m p e l l e r m u s t n o t b e

e x c e s s i v e l y w o r n , o t h e r w i s e

performance will be reduced.

- Consult our services for replacement.

- When carrying out connections

make sure that there is an efficient

earth circuit. The earth wire must be

longer than the live wires, and must

be the first wire to be connected

when the pump is being set up and

the last to be disconnected during

disassembly.

- It is advisable to install a

differential switch. A thermal

overload cutout in the winding

protects against voltage overload in

the single-phase pump motors up to

1.5 KW.

- The three-phase motors must be

protected by the user.

- For three-phase motors the rotation

direction may be inverted; in this case

performance is much lower than the rated

values.

- The correct direction of rotation is found

by raising the water pump by its handgrip:

during starting a clockwise reaction will be

felt (contrary to the direction of the arrow) to

invert the direction of rotation simply invert

two of the phases.

- CAUTION: Never poke fingers or other

objects into hole the pump casing near the

supporting feet to check the direction of

rotation.

- Repair of the pump by personnel not

authorized by the manufacturer will

render the guarantee null and void and will

entail operating dangerous equipment.

-

CAUTION: Any tampering may lead

to performance being reduced and

danger to persons and/or things.

- Where there is the risk of freezing, empty the

well or remove the pump and store it in a suitable

place.

7 - PERIODICAL CONTROLS

- Before doing anything, make sure that the

pump is disconnected from the power source and

there is no possibility of accidental connections.

8. FAULT FINDING CHART

Pump runs constantly or

gives insufficient water.

Pump runs but gives no water.

Motor does not start.

- No electricity supply.

- Motor switched off by level switch.

- Fuses are blown.

- Impeller blocked by impurities.

- Short-circuit in cable or motor.

- Temperature of pumped liquid too high.

- Impeller blocked or partly blocked by impurities.

- Phase failure.

- Voltage too low.

- Pump blocked by impurities.

- Discharge pipe blocked by impurities.

- Liquid level too low. The pump inlet is not completely

submerged in the pumped liquid.

- Pump partly blocked by impurities.

- Discharge pipe partly blocked by impurities.

- Incorrect direction of rotation.

- Pump too small for the application.

FAULT

CAUSE

Thermal relay trips out after

short time of operation.

If in spite of carryng out the above operations, the problem still

persists contact the nearest service centre.

Before attempting to diagnose any fault, make sure that the

electricity supply has been switched off.

The products , referred to in this statement are

in accordance with Directive

73/23/EEC

(the

Low Voltage Directive). Full compliance

with essential requirements of the Directive is

verified for compliance with standard

EN

60335-2-41

.

a

Minimum emptying level:

F 40: 90mm

F 50: 100mm

F 65: 120mm

a

M a x i m u m d i a m e t e r o f s o l i d

particles sucked up:

F 40: 38mm

F 50: 50mm

F 65: 63mm

a

For intermittent duty the water

temperature may reach + 60ºC.

5 - INSTALLATION

- Installation can be a fairly complex

operation.

- It must therefore be carried out by competent

and authorized installers.

- CAUTION: during installation apply all

safety regulations issued by the competent

authorities and use common sense al all times.

- To avoid the backflow of liquid from the

discharge manifold, install a check valve after

the pump delivery outlet (Fig. 1).

- If the pump is installed in a well, the well

must measure at least:

F 40: 400x400x400

F 50: 500x500x500

F 65: 600x600x600

- The starting and stopping level of the pump

can be varied by increasing the free length of

the float.

- For the motor to be cooled correctly the

water level should not drop below :

F 40: 250mm

F 50: 300mm

F 65: 400mm

6 - ELECTRICAL CONNECTIONS

- They are delivered ready to be connected.