GB

10

is easily opened and inspected through the air-tight door.

t

Whenever ues with parallel exits are used it is advisable to raise the upwind chamber

by one element.

t

The chimney tube must never pass across a combustible surface.

The Chimney Cap

The chimney cap must respect the following requirements:

t

It must have the equivalent diameter and internal form of the ue.

t

It must have a useful outlet diameter of not less than double that of the ue.

t

The chimney cap on the roof or that remains in contact with the outside (for example,

in case of open lofts or attics), must be covered with elements in brick or tile and

must, in any case, be well insulated.

t

It must be constructed to prevent rain, snow, and extraneous bodies from entering the

ue and so that the discharge of the products of combustion is not inhibited by wind

from any quarter or strength (windproof chimney cap).

t

The chimney cap must be positioned in such a way as to guarantee the adequate di-

spersion and dilution of the products of combustion and in any case, must be out of

the re ux zone. This zone has different dimensions and forms according to the angle

of inclination of the roof so it is necessary to adopt minimum heights (Fig. 2).

t

The chimney cap must be a wind-proof type and must be above the ridge.

t

Eventual structures or other obstacles that are higher than the chimney cap must not

be too close to the chimney cap itself.

Sizing

Smoke discharge

The discharge system must be for the stove only (it is not permissible to discharge into

ues in common with other devices). The smoke discharge takes place through the 8

cm diameter tube placed at the back. A “T” with a condensation collection cap should

be provided. The smoke discharge of the stove must be connected with the outside

using a steel or black tube (resistant up to 450°C) without obstructions.

The tube must be hermetically sealed. To make the tubes airtight and for their eventual

insulation, it is necessary to use material resistant up to at least 300°C (silicone or putty

for high temperatures). The horizontal sections can be up to 2 m long. It is possible to

have up to three 90° curves.

If the smoke duct is outside it must be insulated (Fig.4).

If the smoke duct is inserted in a ue (Fig.3), this must be certi ed for solid combustibles

and if it is larger than 150 mm in diameter, modi cation is necessary by inserting a tube

and sealing the discharge with respect to the parts in brickwork.

It must be possible to inspect all the sections of the smoke duct. If it is a xed duct it

must have openings for inspection and cleaning.

The adjacent locale must not be used as a garage or be a space without ventilation

or air exchange, a storage area for combustible material or used for an activity

that has a re hazard.

According to the norm UNI 10683/98, the stove must not be in

the same environment where extractors, type B gas devices or in any case, devices that

create lower atmospheric pressure in the locale are found.

External air intake

The stove must be furnished with the air necessary to guarantee the regular functioning

of the combustion and an environmental well being.

t

Be sure that the room where the stove is installed has suf cient aeration and, if ne-

cessary, install an air intake duct with a minimum recommended diameter of 50 mm

to bring in air from the outside.

t

The external air intake must communicate with the stove and positioned so that it is

not obstructed. It must be protected with a permanent non-closable grill or other sui-

table protection provided that the minimum diameter is not reduced.

t

The air ow can also be acquired from a locale adjacent to where the stove is installed

as long as that ow can freely cross the permanent non-closable openings that com-

municate with the outside.

t

The presence in the local adjacent to where the stove is installed, of other devices in

use or of suction devices that cause a contrary draught effect must not create a lower

air pressure in the locale than in the outside environment.

t

In the adjacent locale the permanent openings must respond to the requisites which

are listed in the points above.

Positioning

The stove is furnished with an electrical cable to connect to a 230V 50Hz socket, pre-

ferably with a thermal-magnetic switch. Variations in tension of more than 10% can

compromise the stove (if not already present, an adequate differential switch should be

provided). The electrical system must comply with the norms; verify in particular the ef-

ciency of the ground circuit. The electrical feed cable must be of a diameter adequate

to the power of the device. The stove must be completely level. Verify the weight bearing

capacity of the ooring.

The placement of the stove within the living environment is determined so that the en-

vironment is heated in a uniform manner.

Before deciding where to place the stove, keep in mind that:

t

The air used for combustion must not come from a garage or a space without venti-

lation or air exchange, but from a free space or the outside;

t

The stove should not be installed in a bedroom;

t

Rather it is preferable to install the stove in a large, central room of the house to insure

the maximum heat circulation;sicurare la massima circolazione del calore;

t

A grounded electrical connection is obligatory (if the cable issued with the stove is not

long enough to reach the closet socket, use an extension cable along the oor).

Fire Safety Distance

The stove must be installed respecting the following safety conditions:

t

Minimum distance from the sides and the back must be 40 cm from moderately in-

ammable material;

t

Easily in ammable material must not be place closer than 80 cm in front of the stove;

t

If the stove is installed on an in ammable pavement the stove must be placed on a

slab of material that insulates it from the heat that is wider at the sides by 20 cm and

in the front by 40 cm;

Fig.2: characteristics of the chimney cap

NO

YES

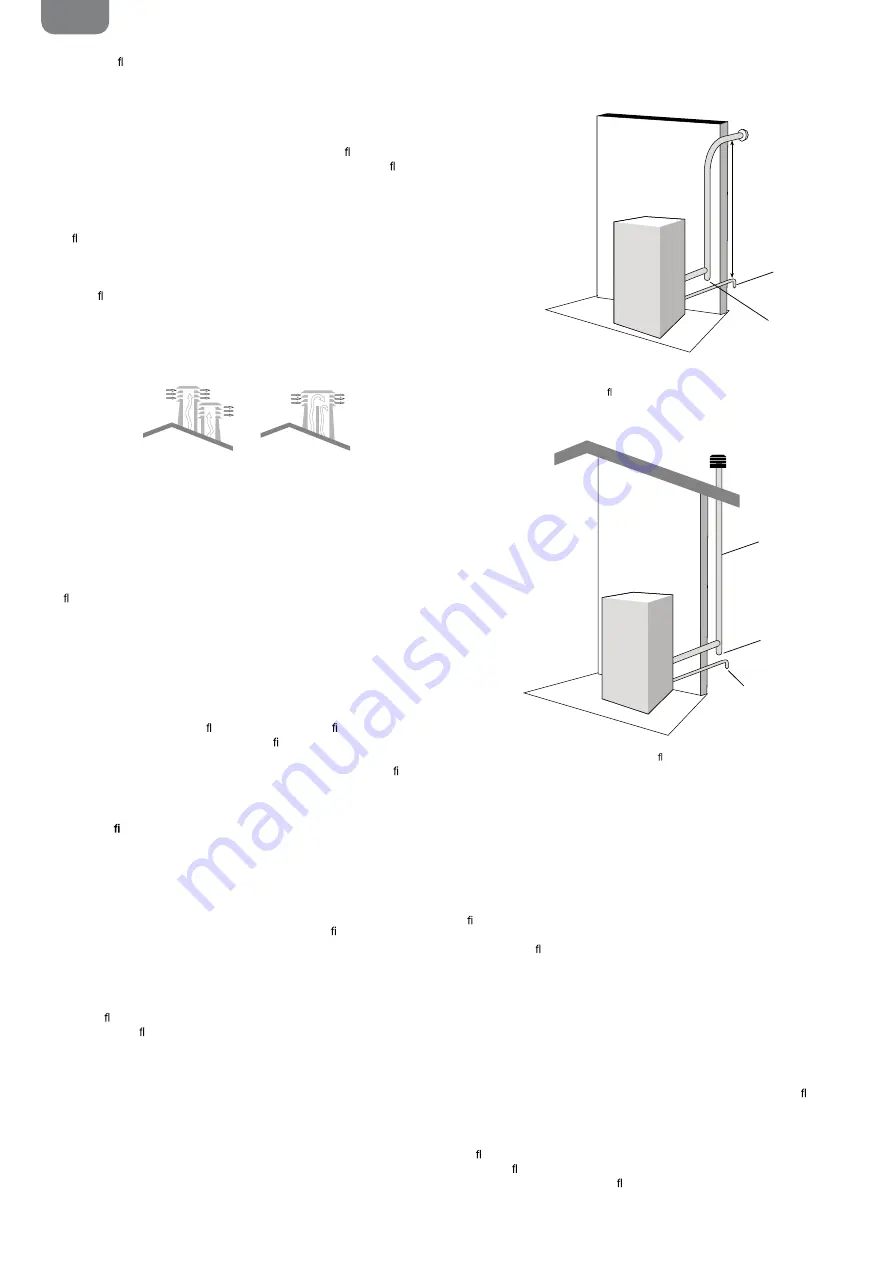

Fig.3: internal ue installation to do according to norms

Fig.4: external ue installation

min. 1,5 m

Condensation collection cap

Air intake

Air intake

Condensation collection cap

Insulated tubing