Summary of Contents for metos 700 72/02CPE

Page 2: ......

Page 4: ...18 2 2004 Rev 1 0 ...

Page 10: ...18 2 2004 Rev 1 0 Safety 4 ...

Page 14: ...18 2 2004 Rev 1 0 Functional description 8 ...

Page 28: ...18 2 2004 Rev 1 0 Troubleshooting 22 ...

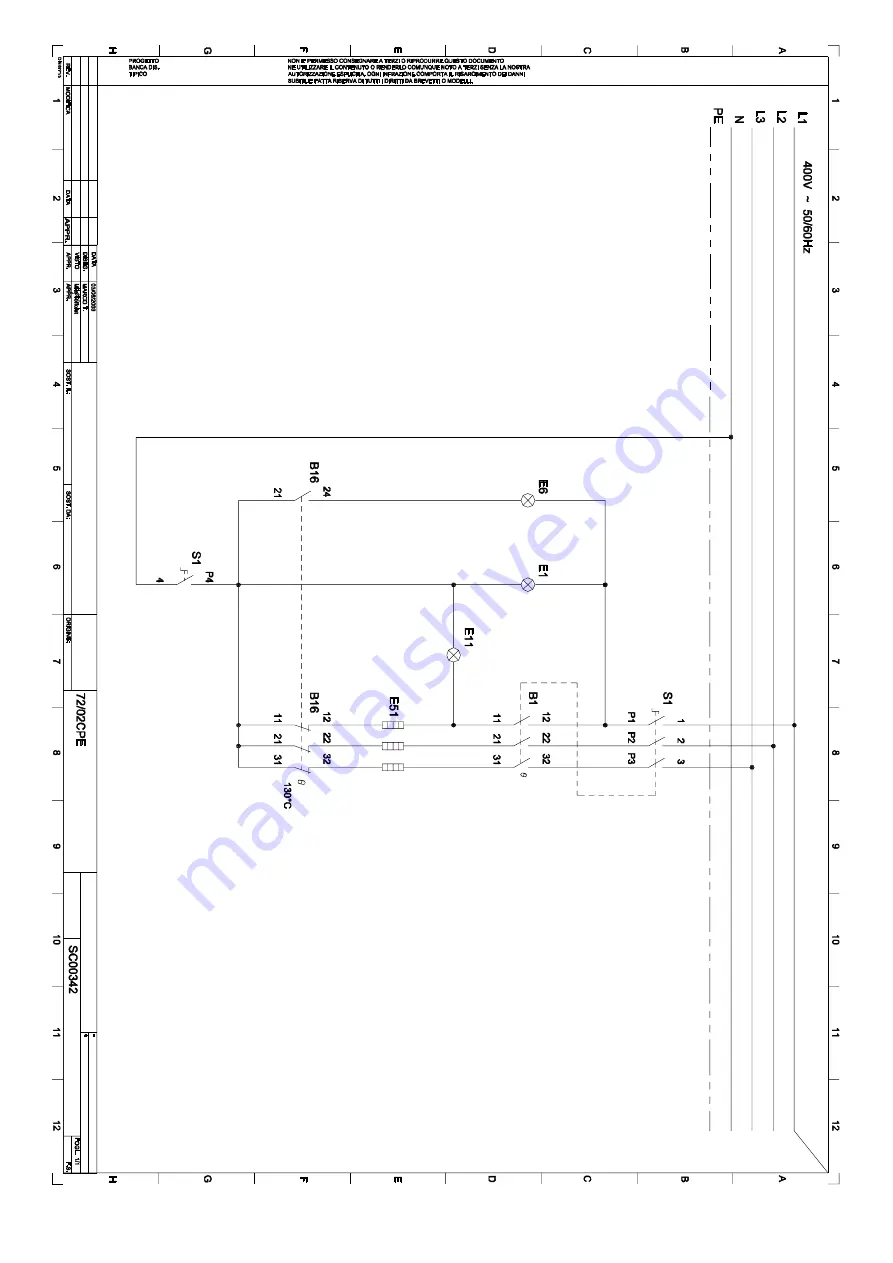

Page 30: ...SC00342 Wiring diagram 72 02 CPE 3 N PE 400V 50 60Hz 65 125 C ...

Page 32: ...SC00343 Wiring diagram 74 02 CPE 3 N PE 400V 50 60Hz 65 125 C ...

Page 36: ...18 2 2004 Rev 1 0 Technical specifications 42 ...

Page 38: ...18 2 2004 Rev 1 0 Technical specifications 44 ...

Page 40: ......