30 |

Page

Oliver Machinery

10014 Planer

Test Run

Each planer has been inspected and calibrated before leaving the factory to meet our quality and

precision standards. Due to various reasons, the machine may need to be re-adjusted when it arrives at

your workshop. It is recommended to complete the test run before using the planer for production

work, and repeat the test run if the planer is relocated.

Step 1: Verify all electrical components are functional.

1.

Remove all tools and debris from the machine.

2.

Push STOP button.

3.

Connect machine to the power source.

4.

Turn the rim of the STOP button clockwise to reset the safety shutoff mechanism.

5.

Press the green START button. The machine should be running with no excessive noise and

vibration.

6.

Press STOP button to turn machine off.

7.

Without resetting the STOP button, attempt to restart the machine by pressing the START

button. The machine should

NOT

start.

8.

Reset the STOP button to restart the machine. Disconnect the machine from power source while

the machine is running, then reconnect machine to power. The machine should

NOT

restart.

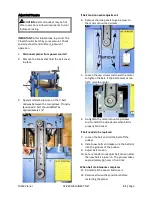

Step 2: Verify the planer headstock is functional and calibrated.

1.

Connect planer to a dust collection system.

2.

Lower the headstock all the way down. The headstock should stop at approximately 1/4" above

the planer table.

3.

Raise the headstock all the way up. Ensure all the anti-kickback fingers can move freely.

4.

Turn on the DRO to check the readings of digital readout. The readings should reflect the

movement of the headstock.

5.

Prepare a piece of good quality, straight grain wood board with flat bottom for a test run. It is

advised to choose a board that is close to 15” wide and at least 2 feet long.

6.

Lower the headstock to remove 1/16” of the workpiece for the test run.

7.

Start the dust collection system and the planer. Gently feed the workpiece towards the infeed

roller. Ones the infeed roller engages the workpiece, it should pull the workpiece through the

planer. Verify the entire top surface has been cut.

8.

Inspect the workpiece for defective finish.

9.

Use a caliper to measure the thickness of each side to ensure the cutterhead is parallel with the

planer table. If the thicknesses are the same, check if the reading is the same as shown on the

headstock height scale.

10.

Check for excessive snipes. Minimum amount of snipe may occur at the ends of the board and it

is expected.

11.

While the machine is running idle, move the feed rate control knob to change feed rate. This

ensures the gearbox and feed rate control knob is functional.

12.

Hit STOP to turn off the planer when all tests complete.

Congratulations for completing the test run! Now your planer is ready for production work. If you

discover any issue from the tests, please refer to the troubleshooting section and maintenance section

for how to diagnose the issue and make adjustments.

Summary of Contents for 10014

Page 2: ......

Page 10: ...10 Page Oliver Machinery 10014 Planer Identification...

Page 11: ...10014 Planer OLIVERMACHINERY NET 11 Page...

Page 12: ...12 Page Oliver Machinery 10014 Planer...

Page 38: ...38 Page Oliver Machinery 10014 Planer Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6...

Page 44: ...44 Page Oliver Machinery 10014 Planer between the cutterhead and the feed rollers...

Page 51: ...10014 Planer OLIVERMACHINERY NET 51 Page WiringDiagram...

Page 52: ...52 Page Oliver Machinery 10014 Planer PartsList Table Assembly...

Page 53: ...10014 Planer OLIVERMACHINERY NET 53 Page Cabinet Assembly...

Page 54: ...54 Page Oliver Machinery 10014 Planer Motor Mount Assembly...

Page 55: ...10014 Planer OLIVERMACHINERY NET 55 Page Headstock Assembly...

Page 56: ...56 Page Oliver Machinery 10014 Planer Gearbox Assembly and Dust Port Assembly...

Page 62: ...62 Page Oliver Machinery 10014 Planer MaintenanceRecord Date Task Operator...

Page 63: ...10014 Planer OLIVERMACHINERY NET 63 Page Notes...