10014 Planer

OLIVERMACHINERY.NET

49

|

Page

Problem

Possible Cause

Possible Solution

Unable to move feed rate

knob.

Machine is not running. Only move feed rate knob while the

machine is running idle at full speed.

Feed rollers does not move

when machine is running.

Gear box is in neutral.

Shift feed rate control knob to set feed rate

to 16/20 FPM while machine is running idle

at full speed.

Workpiece does not feed

smoothly.

Low feed roller

pressure.

Adjust feed roller spring tension.

Incorrect feed roller

height setting.

Adjust feed rollers height so the bottom of

the rollers is below the lowest point of the

cutterhead.

Infeed Roller: 0.020” - 0.027” below.

Outfeed Roller: 0.024” - 0.031” below.

Dirty planer table /

rollers.

Clean table and rollers. Apply paste wax on

the table to reduce drag. Do not use silicon

lubrications on table top.

Belt slipping

Clean belt and the pulleys. Adjust belt

tension.

Stuck planer bed roller. Clean and lubricate roller.

Machine vibrates

excessively or makes

unexpected noise.

Damaged cutter

inserts.

Replace cutter inserts.

Machine stands on

uneven floor.

Reposition on flat, level surface.

Chip deflector is hitting

the cutterhead.

Move chip deflector 1/16”- 1/8” away from

cutterhead.

V-belt worn, slipping or

hitting belt cover.

Clean belt and pulleys. Adjust belt tension.

Replace V-belt if it shows signs of aging.

Feed roller bushing

needs lubrication.

Lubricate bushings.

Bent pulley

Replace pulley.

Improper motor

mounting.

Check and adjust motor mounting.

Loose components.

Tighten fasteners of the component.

Worn bearings

Contact customer service for assistance.

Uneven depth of cut side to

side.

Cutterhead is not

parallel with planer

table.

Adjust cutterhead-table parallelism.

Tolerance: Less than 0.005” side-to-side.

Board thickness does not

match the scale’s

measurement.

Cutterhead height scale

is mispositioned.

Adjust the scale.

Summary of Contents for 10014

Page 2: ......

Page 10: ...10 Page Oliver Machinery 10014 Planer Identification...

Page 11: ...10014 Planer OLIVERMACHINERY NET 11 Page...

Page 12: ...12 Page Oliver Machinery 10014 Planer...

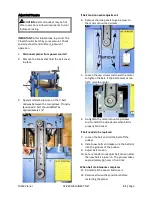

Page 38: ...38 Page Oliver Machinery 10014 Planer Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6...

Page 44: ...44 Page Oliver Machinery 10014 Planer between the cutterhead and the feed rollers...

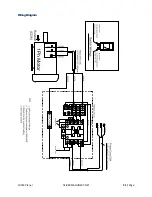

Page 51: ...10014 Planer OLIVERMACHINERY NET 51 Page WiringDiagram...

Page 52: ...52 Page Oliver Machinery 10014 Planer PartsList Table Assembly...

Page 53: ...10014 Planer OLIVERMACHINERY NET 53 Page Cabinet Assembly...

Page 54: ...54 Page Oliver Machinery 10014 Planer Motor Mount Assembly...

Page 55: ...10014 Planer OLIVERMACHINERY NET 55 Page Headstock Assembly...

Page 56: ...56 Page Oliver Machinery 10014 Planer Gearbox Assembly and Dust Port Assembly...

Page 62: ...62 Page Oliver Machinery 10014 Planer MaintenanceRecord Date Task Operator...

Page 63: ...10014 Planer OLIVERMACHINERY NET 63 Page Notes...