16

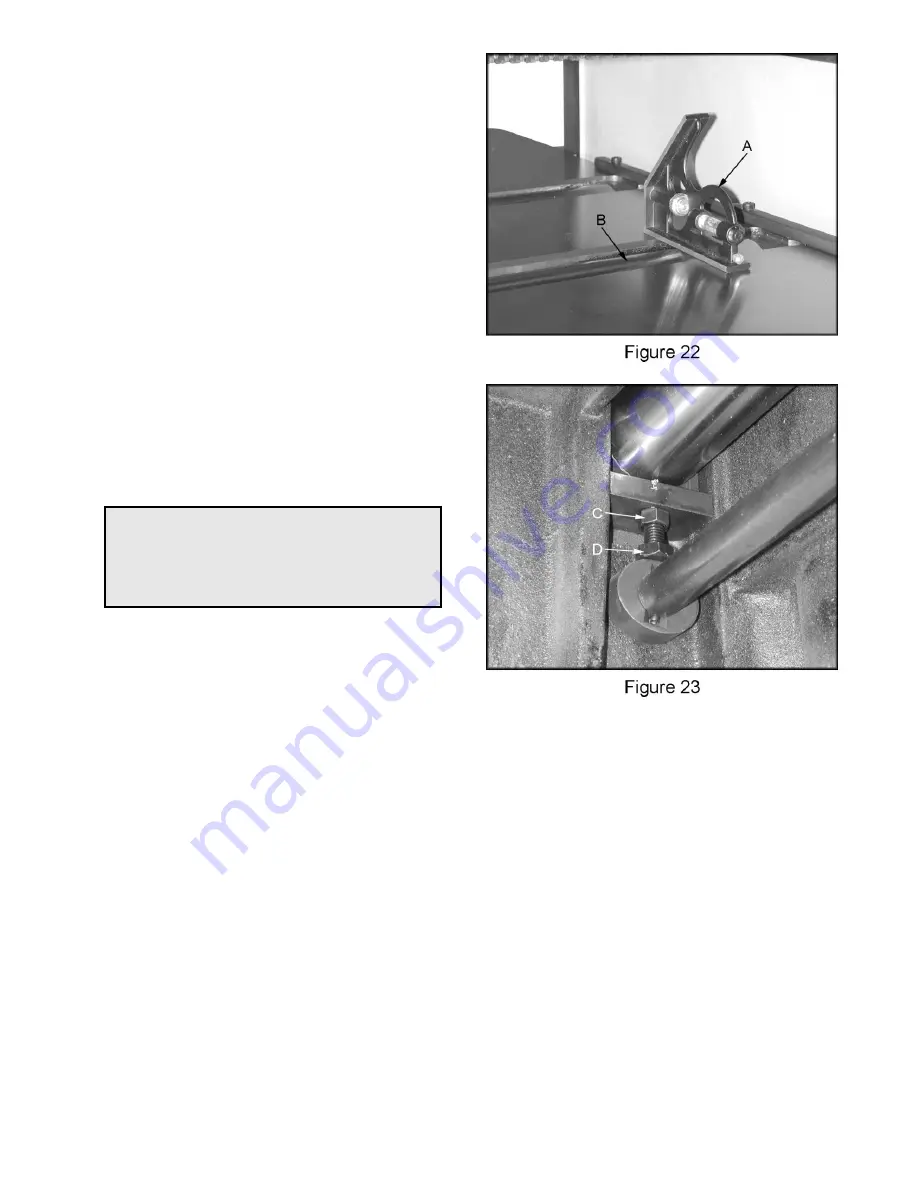

Adjusting Table Rollers

The table rollers come pre-set from the factory

and shouldn’t need any adjustment. If you find

adjustment is necessary, follow the below listed

steps.

1. Lay a straight edge (A, Figure 22) on the

table across the roller (B, Figure 22).

2. Raise the rollers until it contacts the straight

edge and lock the handle. The pointer

should be set at “0”. If not adjust the pointer

to read zero.

Note:

Spin the roller by hand

to know when roller makes contact with the

straight edge.

3. Move straight edge to the opposite side of

bed roller and check to see that the roller

just contacts straight edge. If not loosen the

hex nut (C, Figure 23) and turn the hex cap

bolt (D, Figure 23) to raise or lower the bed

roller until it just contacts the straight edge.

Maintenance

WARNING!

Disconnect the machine from power source

before proceeding with any maintenance,

lubrication or assembly! Failure to comply

may cause serious injury!

Periodic, or regular inspections are required

to ensure that the machine is in proper

adjustment, and that all hardware is tight.

Clean out-feed rollers and table with a non-

flammable solvent to remove pitch, gum and

other unwanted build-up.

Periodically clean the inside of the machine

for dust control.

Keep pulleys and belts free from dirt, dust,

oil and grease. Replace worn v-belts as

needed.

Replace worn knives or sharpen. If a knife

gets nicked stagger the knives. Move one

knife no more than 1/8” to the right and

another knife no more than 1/8” to the left.

There is one limit switch on the planer that

triggers if the hood is opened. Keep it clean

and blown out with an air hose.

Summary of Contents for 4455

Page 19: ......