17

Lubrication

The bearings on the cutterhead

are

factory lubricated and

sealed. They require

no lubrication.

Lubricate the two table elevation screws (A,

Figure 24) as needed. Raise the table and

remove the two screws holding the top of

the accordion cover (B, Figure 24) in place.

Pull the cover down and lightly grease the

elevating screws, see Figure 24.

Use an oiled cloth to wipe the ways (C,

Figure 24) weekly.

The gear box oil should be changed at least

once a year. Remove the drain plug (D,

Figure 25) to drain the oil into an appropriate

container. Replace the drain plug and fill the

gear box with 60 to 90 weight gear oil

through the fill hole (E, Figure 25). Capacity

is 0.494 gallon (1.87L). The sight glass (F,

Figure 25) should be checked periodically

and oil topped off as necessary.

The recommended lubrication for roller

chains used in medium to slow speed

operation is to simply wipe the chain clean.

When there is an appreciable buildup of dust,

dirt or wood shavings, use an oil cloth but

never pour the oil directly on the chain. Over-

oiling defeats the purpose of the lubrication,

since it tends to invite the collection of dust,

shavings, etc. and works into members of the

chain. This hastens wear and leads to

premature replacement.

Weekly oil the bearings on the infeed and

outfeed rollers, through the oil cups located

on the bearing blocks (Figure 26).

Recommended oil type is SAE 30.

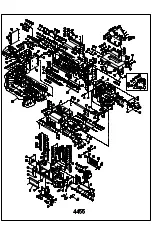

Figure 26

Summary of Contents for 4455

Page 19: ......