9

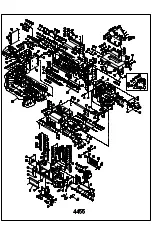

Raising and Lowering Table

Turn the handwheel (A, Figure 6) clockwise to

raise the table. One revolution equals 1/16”.

Table Stop

The socket head cap screw (B, Figure 6) acts as

a stop and prevents you from running the table

into the cutting and feeding assembly.

Opening Hood

Turn the locks (C, Figure 6) clockwise to open

the hood. The hood will open automatically.

Use the handle (D, Figure, 6) to shut the hood.

Calibrating the Thickness Scale

The following sections will describe the use of a

calibrating board. The calibrating board should

be made of a hardwood and have one side that

has been run through a jointer.

1. With the planer turned “OFF – cutterhead

NOT

spinning”, place your calibrating board

jointed surface down on the table and slide it

into the machine.

2. Use the handwheel (A, Figure 6) to raise the

table so that the in-feed roller is about 1/16"

above the calibrating board.

3. Remove calibrating board from planer and

turn the planer “ON”.

4. Turn the handwheel clockwise one complete

revolution to raise the table and run the

calibrating board through the planer.

5. Repeat Step 4 until the planer removes the

entire top surface of your calibrating board.

6. Measure the thickness of the board using a

pair of calipers.

7. Adjust the pointer (E, Figure 6) so that it

reads the measured thickness by loosening

the screw that holds it in place.

Summary of Contents for 4455

Page 19: ......