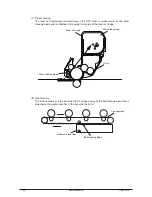

Shading board

Shutter

Toner sensor

(light reception sensor)

Luminous LED

Toner cartridge lever

Toner stir

Toner Sensor Detection Principle

Detection of the low toner is performed by the toner sensor (light reception sensor) installed

inside the equipment and the luminous LED installed inside the cartridge. The shading board is

installed inside the ID and rotates synchronizing with the toner stir. A shutter is attached to the

ID. The shutter synchronizes with the cartridge operation lever and the toner sensor can detect

whether the cartridge is installed properly. If the toner sensor is stained by the toner, etc., or the

ID unit and the toner sensor are not facing each other as specified due to improper setting of

the ID unit or for other reason, the detection may not be executed normally, resulting in a toner

sensor error.

Toner Counter Principle

After the image data is developed into 2 value data to enable printing using the MFP, the print

dot number is counted by the LSI. The amount of the toner used is counted from the above

count value and the remaining amount is displayed. On the other hand, detection of the low

toner by the toner sensor is physically made when the amount of the toner remaining in the

cartridge comes to be under certain amount.

Principles of ID, Belt and Fusing Counter

ID Counter

: 1 count is the value of one third of the amount of drum rotation when three

A4 sheets of paper are continuously printed.

Belt Counter :

1 count is one third of the amount of the belt rotation when three A4 sheets

of paper are continuously printed.

Fusing Counter: Standard is the length of Legal 13 inches sheet of paper. 1 count is the sheet

of paper under that length and when the length is more than that, the number

of count is decided by multiples of Legal 13 inches. (Number under the

decimal point is rounded up.)

30

Service Manual

Y108500-4