2PX/2PY-2

2-4-2

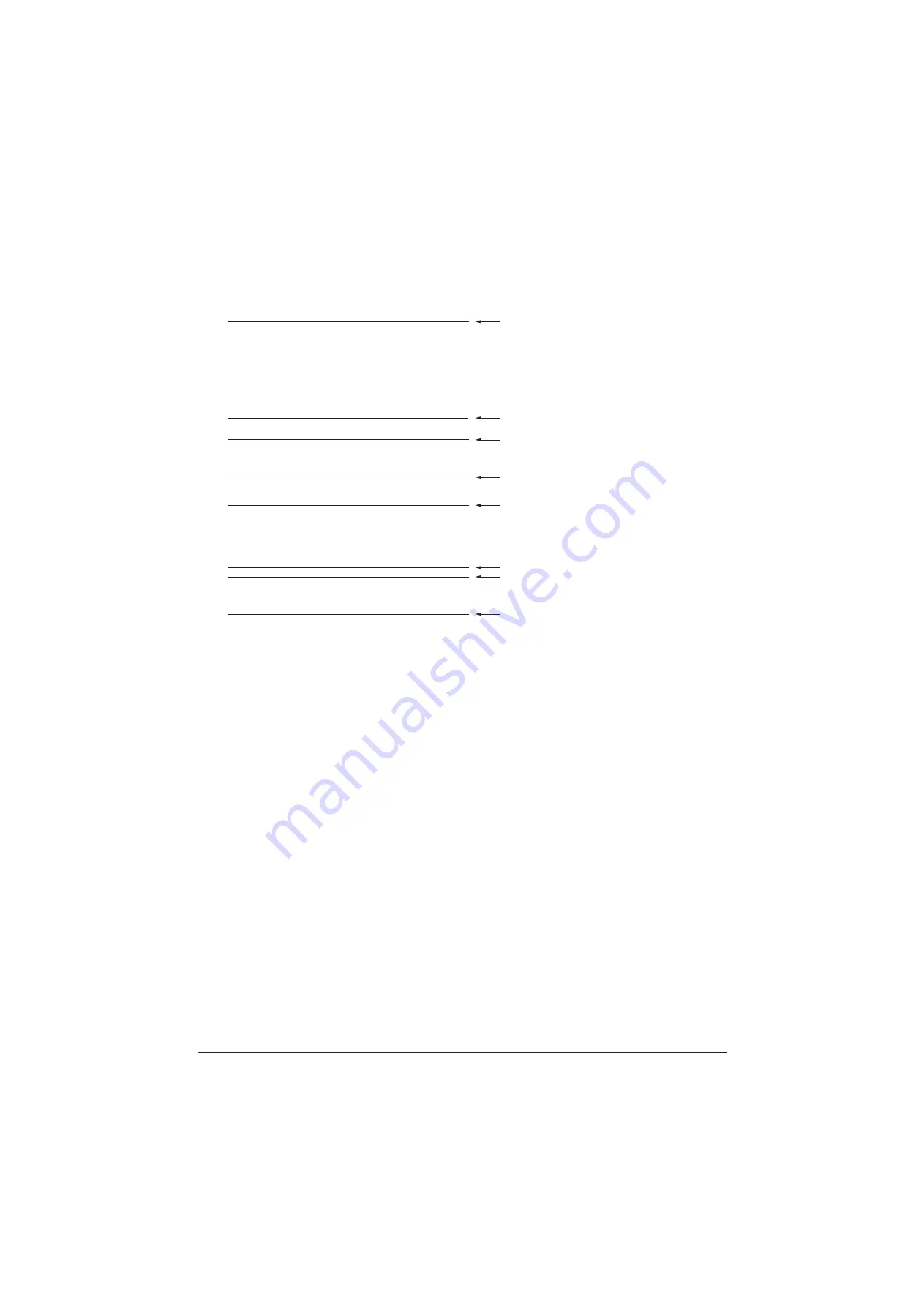

(2) Repetitive defects gauge

* : The repetitive marks interval may vary depending on operating conditions.

31 mm/1

1/4

"

38 mm/1

1/2

"

First occurrence of defect

50 mm/1

15/16

"

50 mm/1

15/16

"

59 mm/2

5/16

"

79/3

1/8

" mm

82/3

1/4

" mm

94/3

11/16

" mm

Rear registration roller

Charger roller

Front registration roller

Sleeve roller

Transfer roller

Press roller

Heat roller

Drum

Service Manual

Y116670-7

Summary of Contents for d-Color MF2613 Plus

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 27: ...1 2 3 Service Manual Y116670 7 This page is intentionally left blank ...

Page 134: ...2PX 2PY 1 3 96 This page is intentionally left blank Service Manual Y116670 7 ...

Page 237: ...2PX 2PY 1 5 51 9 Remove the scanner unit Figure 1 5 78 Scanner unit Service Manual Y116670 7 ...

Page 280: ...2PX 2PY 1 5 94 This page is intentionally left blank Service Manual Y116670 7 ...

Page 284: ...Service Manual Y116670 7 This page is intentionally left blank ...

Page 324: ...2PX 2PY 2 2 10 This page is intentionally left blank Service Manual Y116670 7 ...

Page 372: ...1 1 INSTALLATION GUIDE INSTALLATION GUIDE FOR Card Authentication Kit D ...

Page 373: ...1 2 3 4 5 a a c CARD READER CARD READER HOLDER D b ...

Page 374: ...10 b c 6 8 9 7 ...

Page 375: ...UPDATINGSTATUS DATE UPDATEDPAGES PAGES CODE 07 2014 1ST EDITION 375 Y116670 7 ...