2KL/2KK

1-1-3

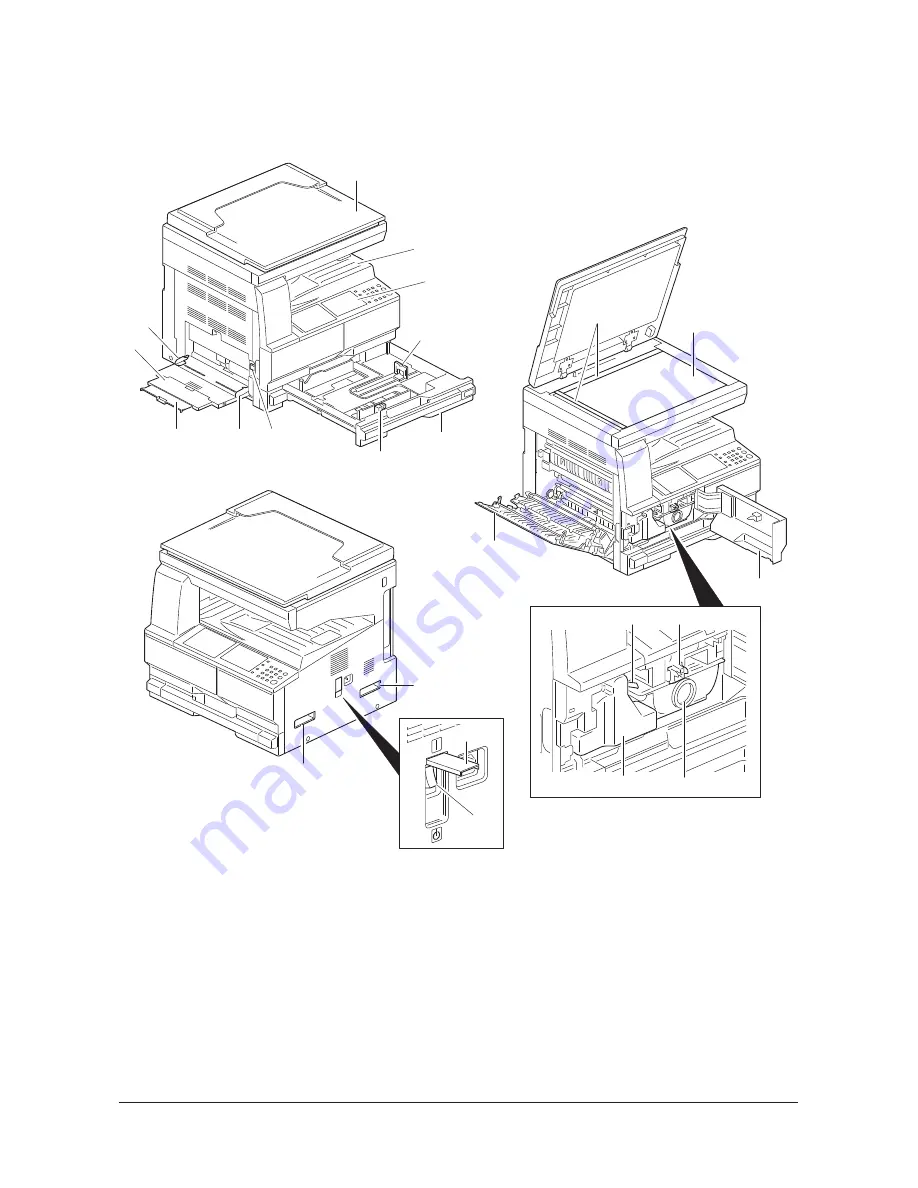

1-1-2 Parts names

(1) Body

Figure 1-1-1

1

11

12

10

8

7

4

5

6

2

3

10

19

19

20

21

18

14

13

15

17

16

9

1. Original cover (option)

2. Output tray

3. Operation panel

4. Cassette

5. Paper width adjusting tab

6. Paper length adjusting tab

7. Left cover handle

8. MP tray

9. MP tray extension

10. Slider

11. Contact glass

12. Original size indicator plates

13. Left cover

14. Front cover

15. Toner container release lever

16. Toner container

17. Charger cleaner rod

18. Waste toner box

19. Handles for transport

20. Main power switch

21. Main power switch cover

Y110980-1 Service Manual

Summary of Contents for d-Copia 1800

Page 1: ...d Copia 1800 d Copia 2200 Digital Copier SERVICE MANUAL Code Y110980 1...

Page 4: ...This page is intentionally left blank...

Page 10: ...This page is intentionally left blank...

Page 14: ...2KL 2KK This page is intentionally left blank...

Page 20: ...2KL 2KK 1 1 6 This page is intentionally left blank Service Manual Y110980 1...

Page 38: ...2KL 2KK 1 2 18 This page is intentionally left blank Service Manual Y110980 1...

Page 108: ...2KL 2KK 1 3 70 This page is intentionally left blank Service Manual Y110980 1...

Page 142: ...2KL 2KK 1 4 34 This page is intentionally left blank Service Manual Y110980 1...

Page 198: ...2KL 2KK 1 5 56 This page is intentionally left blank Service Manual Y110980 1...

Page 224: ...2KL 2KK 2 2 6 This page is intentionally left blank Service Manual Y110980 1...

Page 240: ...2KL 2KK 2 3 16 This page is intentionally left blank Service Manual Y110980 1...

Page 271: ...INSTALLATION GUIDE FOR PAPER FEEDER...

Page 285: ...INSTALLATION GUIDE FOR DUPLEX UNIT...

Page 294: ...INSTALLATION GUIDE FOR Printing System Z...

Page 297: ...UPDATING STATUS DATE UPDATED PAGES PAGES CODE 09 2009 1ST EDITION 297 Y110980 1...