Service Manual

Y100250-4

8-7

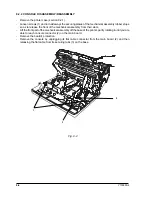

8.6 ROLLER GEAR ADJUSTMENT

MACHINE CONDITION:

Upper mechanical assembly closed.

OBJECTIVE ADJUSTMENT:

Mesh between cogged wheels (1) and (2) with a maximum radial clearance of 0.2 mm between the teeth.

Check this clearance throughout the entire wheel rotation.

Adjust the two matings on the right-hand side of the printer.

PROCEDURE:

Turn screws (3) that secure the bushing, tightening them with a torque equivalent to 6 +0.5 Kgcm.

Fig. 8-6

Note:

Perform this adjustment on both gear pairs on the printer.

0,2

1

2

< 0.2

3

Post-adjustment

clearance

Summary of Contents for PR2 E

Page 1: ...PR2 E Printer SERVICE MANUAL CodeY100250 4...

Page 4: ...OOOOO...

Page 40: ...Y100250 4 3 6 Fig 3 3 Print Test Example PR2 E Basic Version...

Page 41: ...ServiceManual Y100250 4 3 7 Fig 3 4 Print Test Example PR2 E Horizontal Magnetic Device...

Page 92: ...OOOOO...

Page 98: ...Y100250 4 6 6 Fig 6 3 PR2MAGN Card 6 3 2 VIEW OF THE PR2MAGN CARD...

Page 106: ...OOOOO...

Page 124: ...OOOOO...

Page 149: ...UPDATING STATUS DATE UPDATED PAGES PAGES CODE 04 2001 1ST EDITION 149 Y100250 4...